Welding stainless steel is not just a task, it's an intricate dance of heat, metal, and technique. With its robust strength and steadfast resistance to corrosion, stainless steel has become the backbone of industries ranging from high-rise buildings to the culinary arts. In this comprehensive guide, we delve into the nuances of torch welding stainless steel, a skill that marries the precision of science with the elegance of art. We'll explore key techniques, the best equipment for the task, and insider tips to ensure your welding is as resilient as the material itself.

Can You Torch Weld Stainless Steel?

The answer is a resounding yes, but it's not without its challenges. Stainless steel's laudable attributes come at the cost of requiring meticulous attention to detail and specialized techniques to maintain its integrity during the welding process. Torch welding, a favored method among experts and enthusiasts, offers the precision necessary to tackle these challenges head-on.

Choosing the Perfect Welding Machine

When faced with the question, "What welding machine for stainless steel?" the decision often comes down to two front-runners: TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding machines, both boast their strengths, but the right choice hinges on your project's unique needs, including material thickness and the finish you're aiming for.

TIG Welding: Precision's Best Friend

TIG welding stands out as the preferred method for stainless steel. Renowned for its precision, TIG welding employs a non-consumable tungsten electrode, offering unmatched control over heat and ensuing weld quality—both critical factors when working with stainless steel.

MIG Welding: Efficient and User-Friendly

For projects requiring longer welds or involving thicker materials, MIG welding steps into the limelight. Faster than its TIG counterpart, MIG uses a consumable wire electrode, making it an easier technique for beginners to pick up without sacrificing efficiency.

Essential Techniques for Torch Welding Stainless Steel

Torch welding stainless steel demands more than just selecting the right welding machine; it requires a deep understanding of the techniques that can make or break the integrity of a weld. Here are some essential techniques to enhance your torch welding prowess:

Pre-Weld Preparation: The Foundation of Success

Before igniting your torch, preparation is key. Ensure that the stainless steel surface is impeccably clean and free from any contaminants like oil, grease, or paint, which can cause weld defects. Use a stainless steel brush dedicated solely to this task to avoid cross-contamination from other metals.

Heat Control: Walking the Thin Line

Stainless steel is sensitive to heat; too much can lead to warping, while too little can result in weak welds. Mastering the art of heat control is vital, and one way to manage this is by using a heat sink, which absorbs excess heat and helps distribute it more evenly.

Post-Weld Treatment: Preserving Weld Quality

After welding, the cooling process begins, but the job isn't done yet. To prevent oxidation and maintain corrosion resistance, a process known as passivation may be applied, which involves cleaning and treating the weld area with chemicals that remove surface contaminants and support the formation of a protective oxide layer.

The Role of Welding Torches in Stainless Steel Fabrication

A welding torch is the extension of the welder's hand, and choosing the right one is crucial. INWELT TECH offers a diverse collection of welding torches and guns designed to meet the specific demands of stainless steel welding, ensuring precision, durability, and ease of use.

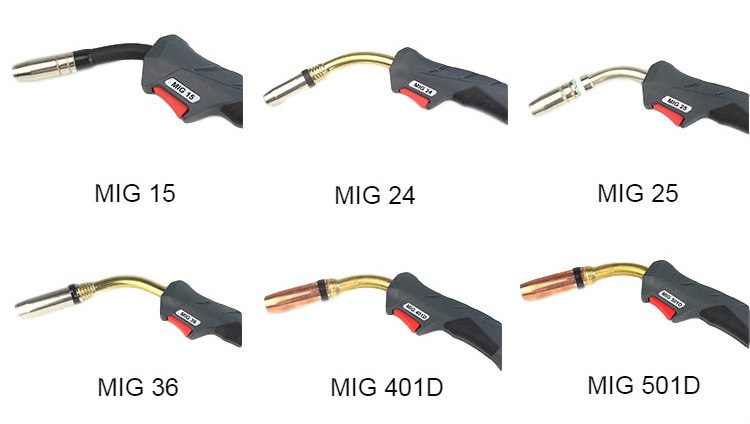

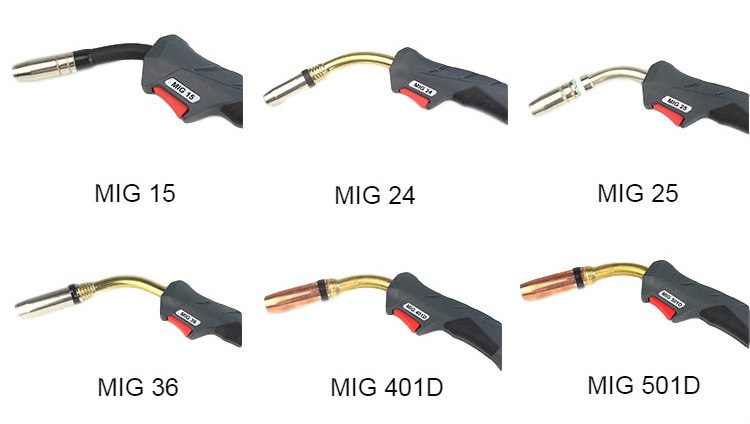

MIG Welding Torches: The Power of Versatility

With options such as the MB, PANA, and PSF series, INWELT's MIG welding torches provide versatility without compromising performance. The Spool Gun and Fume Extraction Gun further cater to specialized needs, offering solutions for intricate welds and safer work environments, respectively.

TIG Welding Torches: The Essence of Control

The WP series, including models WP9, WP17, WP18, and WP26, represents the pinnacle of control. These TIG welding torches are engineered to deliver precise arcs and consistent welds, essential when working with stainless steel's delicate nature.

Maximizing Efficiency with Welding Accessories

The right accessories not only make the welding process more efficient but also enhance the final outcome. At INWELT TECH, an array of welding accessories is available to complement your torch welding techniques for stainless steel.

MIG Welding Accessories: Enhancing Your Welding Experience

From contact tips to nozzles and liners, the right MIG welding accessories ensure smooth wire feeding and protect your welding gun from spatter. INWELT TECH's selection is designed to maintain the precision and longevity of your MIG setup.

TIG Welding Accessories: Refining Precision

TIG welding is known for its precision, and using the appropriate accessories is non-negotiable. Tungsten electrodes, collets, and gas lenses are just a few of the TIG accessories INWELT TECH provides to help you achieve those perfect, clean welds on stainless steel.

Plasma Cutting Accessories: Cutting with Confidence

For projects that require cutting stainless steel, having reliable plasma-cutting accessories is essential. INWELT TECH's plasma torches and consumables ensure that you can cut through stainless steel with ease and accuracy.

Safety Gear: The Unsung Hero of Welding

While the focus is often on the welding process itself, safety gear is paramount. The intense light and heat generated during welding can pose significant risks without proper protection.

Welding Helmets: Your First Line of Defense

A high-quality welding helmet is a non-negotiable tool in any welder's arsenal. INWELT TECH offers laser-safety helmets that provide not only protection from ultraviolet and infrared light but also ensure clear visibility during the welding process.

Laser Safety: Protecting Your Vision

Beyond traditional welding helmets, INWELT TECH's laser-safety goggles and windows offer additional layers of protection, especially when working with cutting-edge laser welding technologies that demand stringent safety measures.

The INWELT TECH Advantage: Quality and Innovation

Choosing INWELT TECH for your welding needs means opting for a partner that values quality and innovation. With a range of welding torches, accessories, and safety gear optimized for stainless steel welding, INWELT TECH stands as a leader in the welding industry.

Our Commitment to Excellence

At INWELT TECH, we understand the intricacies of welding stainless steel. Our factory and lab are at the forefront of research and development, ensuring that every product we offer meets the highest standards of quality and performance.

Quality Control: A Staple of Trust

With stringent quality control measures in place, we guarantee that our welding products are not just effective but also reliable. Our commitment to excellence is further reflected in the certifications we've earned and the positive reviews from our customers.

Staying Ahead: The Importance of Continued Education in Welding

The world of welding is always advancing, with new techniques and technologies emerging regularly. For professionals in the industry, continual learning is not just an option—it's a necessity to stay competitive and proficient.

Embracing New Welding Technologies

INWELT TECH is committed to innovation, which is reflected in our product offerings and the resources we provide to our customers. By staying informed about the latest advancements, welders can take advantage of new tools and methods that can improve efficiency and weld quality.

The Value of Customer Service and Support

At INWELT TECH, we believe that the sale is just the beginning of our relationship with our customers. Our dedicated customer service team is always ready to assist international customers with any questions, providing support that extends far beyond the purchase.

Post-Sale Service: Ensuring Long-Term Satisfaction

Our post-sale services are designed to ensure that you continue to get the most out of our welding products. Whether it's assistance with troubleshooting, guidance on product usage, or answering technical queries, we are here to help.

Conclusion: The Art and Science of Stainless Steel Welding

Welding stainless steel with a torch is an intricate balance of art and science. By understanding the techniques, choosing the right equipment, and utilizing the proper accessories and safety gear, welders can achieve high-quality results that are both aesthetically pleasing and structurally sound.

At INWELT TECH, we are proud to support welders in this endeavor with our high-quality welding torches, accessories, and safety gear. With a focus on innovation, quality, and customer service, we are dedicated to helping you accomplish your welding projects with excellence and ease.

Embrace the challenge of stainless steel welding with the confidence that comes from using INWELT TECH's trusted products and support. As you master the torch and refine your technique, you'll not only build structures but also a reputation for quality craftsmanship that stands the test of time.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių