If you've ever thought about picking up a MIG welder but didn't want to deal with heavy gas tanks, you're probably wondering—can you MIG weld without gas? The short answer is yes, but it's not as simple as just leaving the gas out of the equation. Gasless MIG welding exists, but it works a little differently than traditional MIG welding. Whether you're a beginner trying to simplify your setup or a pro welder looking for convenience, gasless welding might be an option worth exploring. Let's dive into what it is, how it works, and whether it's the right choice for you.

Understanding MIG Welding

Before we talk about gasless MIG welding, let's take a quick look at what MIG welding is and why shielding gas is typically a key part of the process.

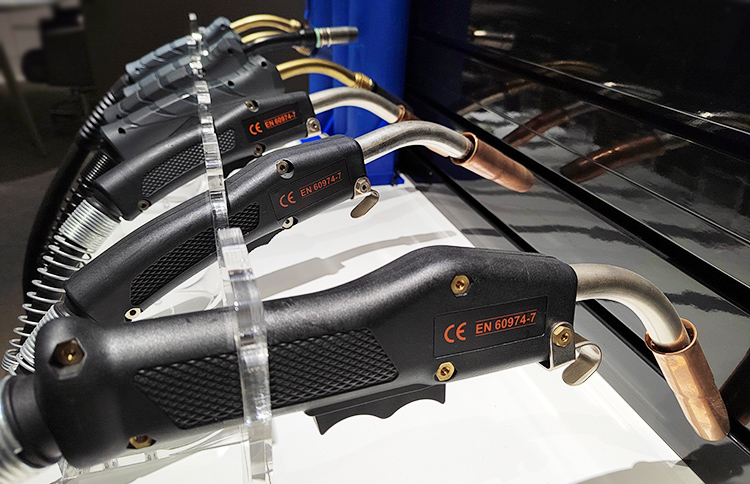

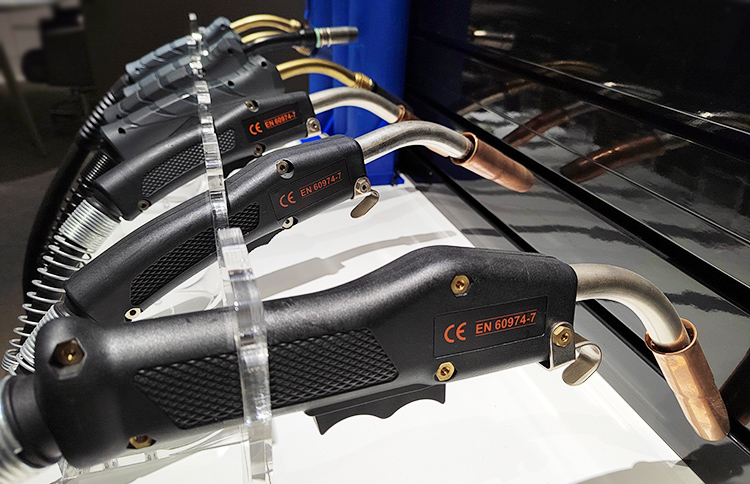

What is MIG Welding?

MIG welding, short for Metal Inert Gas welding, uses a continuously fed wire electrode to create an arc that melts and fuses metal. It's one of the most popular welding methods because it's fast, easy to learn, and versatile. A key part of the process is the shielding gas, which protects the weld pool from contaminants in the air like oxygen and moisture. Without this protection, the weld can weaken or become porous.

The Role of Shielding Gas in MIG Welding

Shielding gas, usually a mix of argon and CO2, creates a barrier around the weld. This prevents oxidation and ensures a clean, strong bond. It's essential for traditional MIG welding, especially when working with materials that need precise, high-quality welds. But what happens when you remove the shielding gas? That's where gasless MIG welding comes in.

What Does“Gasless” MIG Welding Mean?

Gasless MIG welding isn't actually gas-free—it just doesn't rely on an external shielding gas. Instead, it uses a special type of wire called flux-cored wire that generates its own shielding gas during the welding process.

Flux-Cored Wire: The Key to Gasless MIG Welding

Flux-cored wire is the secret sauce for gasless MIG welding. It has a hollow core filled with flux, which creates a protective gas shield when heated. This eliminates the need for an external gas tank, making the setup simpler and more portable. Think of it like a self-contained system—everything you need for shielding is built right into the wire.

Differences Between Gas MIG Welding and Gasless MIG Welding

The biggest difference between gas and gasless MIG welding is where the shielding comes from. Traditional MIG welding uses an external gas supply, while gasless welding relies on flux-cored wire. This difference affects everything from the weld quality to the types of projects each method is best suited for.

Advantages of Gasless MIG Welding

Gasless MIG welding has a lot going for it, especially when it comes to convenience and practicality.

Portability and Outdoor Use

One of the biggest perks of gasless welding is that it's perfect for outdoor projects. Traditional MIG welding struggles in windy conditions because the shielding gas can get blown away. With flux-cored wire, you don’t have to worry about that, making gasless welding ideal for repairs or construction work outside.

Cost Savings

Gasless welding can save you money in the long run. You don't need to buy or refill gas tanks, which can be expensive. Plus, the equipment setup is simpler, so you might save on upfront costs as well.

Simplicity and Convenience

If you’re just getting started with welding, gasless MIG welding is easier to manage. There are fewer components to worry about, and you don’t have to deal with setting up and regulating gas flow. It’s a great option for beginners or quick, on-the-go projects.

Limitations of Gasless MIG Welding

While gasless MIG welding has its advantages, it's not without its downsides. Here are some challenges you might face.

Spatter and Cleanup

Flux-cored wire tends to produce more spatter than traditional MIG welding. This means you'll spend more time cleaning up after your welds, and the finished product might not look as smooth or polished.

Weld Quality and Strength

Gasless MIG welding isn't always as precise as its gas-shielded counterpart. The welds can be slightly weaker or less clean, making it less suitable for critical or high-quality applications.

Limited Material Applications

Gasless welding works well for mild steel and thicker materials, but it struggles with thinner metals or materials that require a delicate touch. If you’re working on thin aluminum or stainless steel, traditional MIG or TIG welding might be a better choice.

How to Set Up MIG Welding Without Gas

If you’re ready to give gasless MIG welding a try, here’s how to set yourself up for success.

Choosing the Right Flux-Cored Wire

Not all flux-cored wires are created equal, so choose one that matches your project. Look for wire designed for gasless welding and make sure it’s compatible with your welder.

Adjusting Your MIG Welder

Gasless welding requires slightly different settings than traditional MIG welding. You'll need to reverse the polarity on your welder (set it to DCEN, or Direct Current Electrode Negative) and adjust the voltage and wire feed speed to match the flux-cored wire.

Techniques for Successful Gasless Welding

To get the best results, keep your welding angle consistent and maintain a steady travel speed. Work in short bursts if needed to avoid overheating the material, and always clean the metal surface before welding to prevent contamination.

Gasless MIG Welding vs. Other Welding Methods

How does gasless MIG welding compare to other popular welding methods? Let’s take a look.

Gas MIG Welding vs. Gasless MIG Welding

Gas-shielded MIG welding produces cleaner, stronger welds and is better for thin materials. Gasless MIG welding, on the other hand, is more portable and works better in outdoor or windy conditions.

Gasless MIG Welding vs. Stick Welding

Both gasless MIG welding and stick welding are good for outdoor use, but gasless MIG welding is faster and produces less slag. Stick welding, however, might be a better option for very thick materials or rough environments.

Gasless MIG Welding vs. TIG Welding

TIG welding is all about precision and quality, making it ideal for thin or delicate materials. Gasless MIG welding can’t match TIG’s finesse but is much faster and easier to set up.

When Should You Use Gasless MIG Welding?

Gasless MIG welding isn’t the best choice for every job, but it excels in certain situations.

Outdoor Environments

If you’re working outside in windy conditions, gasless MIG welding is the way to go. The flux-cored wire’s built-in shielding makes it immune to wind interference.

DIY and Hobby Projects

If you’re a hobbyist or DIY enthusiast, gasless MIG welding is a simple, cost-effective option. It's easy to learn and doesn't require a lot of expensive equipment.

Repairs and Quick Fixes

For quick repairs or on-the-go welding jobs, gasless MIG welding is hard to beat. Its portability and simplicity make it perfect for patching up fences, machinery, or other metal structures.

Safety Considerations for Gasless MIG Welding

Safety is always a priority when welding, and gasless MIG welding is no exception.

Protecting Yourself from Fumes

Flux-cored wire produces more fumes than traditional MIG welding, so make sure you're working in a well-ventilated area or using a fume extractor. Always wear a welding helmet and respirator if necessary.

Managing Heat and Spatter

Gasless welding generates a lot of heat and spatter, so wear protective gloves, a welding jacket, and safety glasses. Keep flammable materials away from your workspace to reduce the risk of fire.

Conclusion

So, can you MIG weld without gas? Absolutely! Gasless MIG welding, powered by flux-cored wire, offers a convenient and portable alternative to traditional gas-shielded MIG welding. While it has its limitations—like increased spatter and slightly lower weld quality—it's a fantastic option for outdoor projects, repairs, and hobby welding. Just remember to choose the right wire, adjust your settings, and prioritize safety. With the right approach, gasless MIG welding can be a valuable tool in your welding arsenal. Happy welding!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių