Welding is a craft that combines skill and technology, and when it comes to choosing the right tools, MIG torches are often a top choice for professionals and hobbyists alike. But what makes them so popular? Let’s dive into the advantages of MIG torches.

Introduction to MIG Torches

Metal Inert Gas (MIG) torches are a staple in the welding world. Known for their efficiency and ease of use, these torches are ideal for both beginners and seasoned welders.

Understanding MIG Welding

To appreciate MIG torches fully, it's essential to understand the basics of MIG welding.

Basics of MIG Welding

MIG welding involves using a continuous wire feed as an electrode and a shielding gas to protect the weld from contamination. It’s straightforward, making it accessible for many.

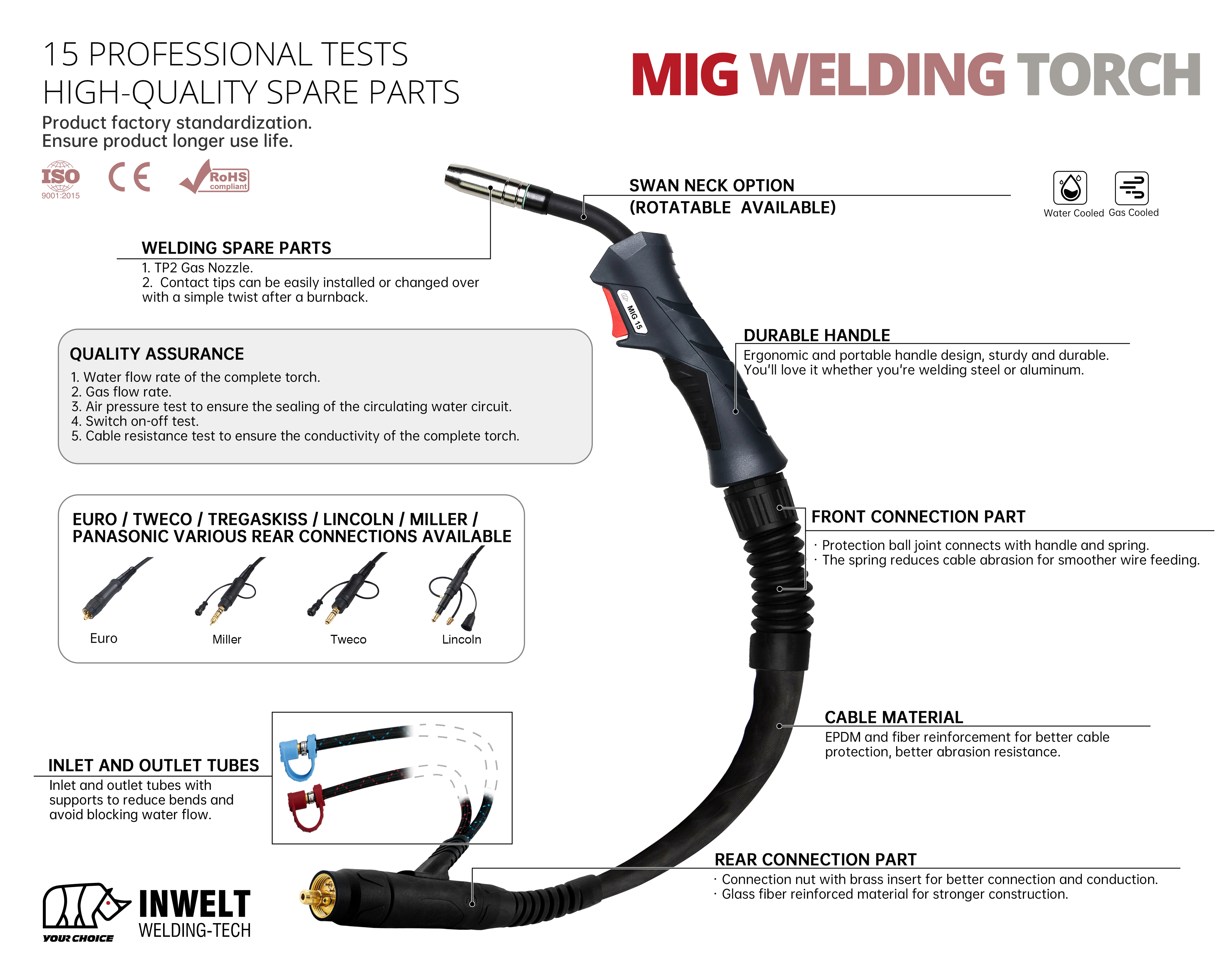

How MIG Torches Work

MIG torches deliver the electrode wire and shielding gas to the weld pool, making them crucial for the welding process's success.

Key Advantages of MIG Torches

MIG torches offer several benefits that make them stand out among other welding tools.

Ease of Use

One of the primary advantages is their simplicity. MIG torches are user-friendly, requiring minimal setup and adjustment, which is great for those new to welding.

Efficiency and Speed

MIG welding is known for its speed. The continuous wire feed allows for fast welding, which is perfect for large projects needing quick turnaround times.

Versatility

MIG torches can handle a variety of metals, including steel, aluminum, and stainless steel, making them versatile for different projects.

Cost-Effectiveness

MIG welding is generally cost-effective due to its efficiency and the relatively low cost of consumables like wire and gas.

Detailed Analysis of MIG Torch Benefits

Let’s break down these advantages further.

Improved Precision

MIG torches allow for precise control over the welding process.

Accurate Welds

The consistent wire feed ensures smooth, even welds, reducing the need for extensive clean-up or rework.

Reduced Spatter

MIG torches produce less spatter compared to other methods, resulting in cleaner work and less post-weld cleaning.

Enhanced Safety Features

Safety is paramount in welding, and MIG torches come equipped with features to protect the user.

Ergonomic Design

Many MIG torches are designed with ergonomics in mind, reducing fatigue during long welding sessions.

Safety Mechanisms

Built-in safety features like thermal overload protection help prevent accidents and ensure the torch operates safely.

Durability and Maintenance

MIG torches are built to last, making them a reliable choice.

Longevity of Equipment

High-quality materials and construction mean that MIG torches can withstand heavy use over time.

Simple Maintenance Practices

Routine maintenance is straightforward, extending the life of the equipment and ensuring consistent performance.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių