Premium Welding Accessories & Consumables for Professional Welders | INWELT

Discover INWELT's comprehensive range of welding accessories and consumables designed for durability, precision, and efficiency. As a leading manufacturer, we offer high-quality MIG, TIG, plasma, and gas cutting solutions to meet the demands of industrial welding projects. Whether you're looking for reliable torches, electrodes, or spare parts, our products ensure optimal performance and safety. Shop now for fast shipping and competitive pricing on welding consumables online.

Why Choose INWELT Welding Accessories & Consumables?

At INWELT, we prioritize innovation and reliability in every product. Our welding accessories are engineered to withstand harsh environments, reducing downtime and enhancing weld quality. Key benefits include:

Superior Materials: Heat-resistant and corrosion-proof components for long-lasting use.

Customizable Options: Tailored series for various welding applications.

Expert Support: Comprehensive FAQs and guides to help you select the right consumables.

Explore our categories below to find the perfect welding supplies for your needs.

MIG Welding Torches & Accessories

Our MIG welding torches are built for high-volume production and precision arc control. Ideal for automotive, fabrication, and construction industries, these torches feature ergonomic designs and easy maintenance.

BND Series MIG Torches

Robust construction for heavy-duty use.

Compatible with standard MIG welders.

Available in air-cooled and water-cooled variants.

BZL Series MIG Torches

Lightweight and flexible for extended reach.

Integrated gas diffuser for stable shielding.

Perfect for aluminum and stainless steel welding.

PANA Series MIG Torches

High-amperage capacity up to 500A.

Swirl ring technology for uniform gas flow.

Quick-change consumables to minimize setup time.

PSF Series MIG Torches

Push-pull design for soft wire feeding.

Anti-spatter nozzles included.

Suited for robotic welding systems.

TR Series MIG Torches

Compact size for tight spaces.

Euro-style connections for versatility.

Enhanced trigger durability.

TW Series MIG Torches

Browse our full MIG Welding Accessories collection for spare parts and kits.

TIG Welding Accessories & Consumables

TIG welding demands precision—our accessories deliver just that. From torch kits to collets and nozzles, INWELT's TIG consumables ensure clean, high-quality welds on thin materials.

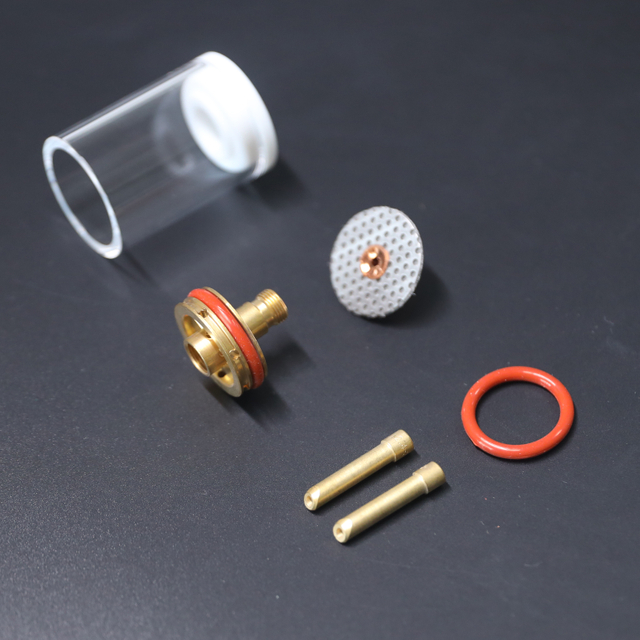

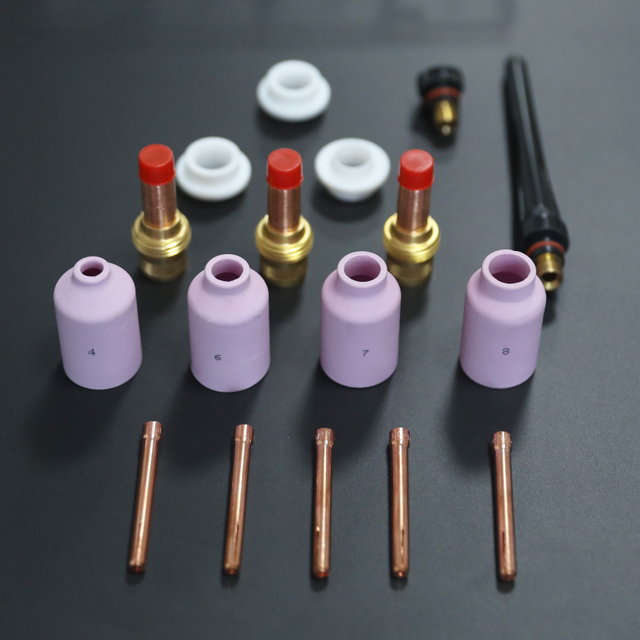

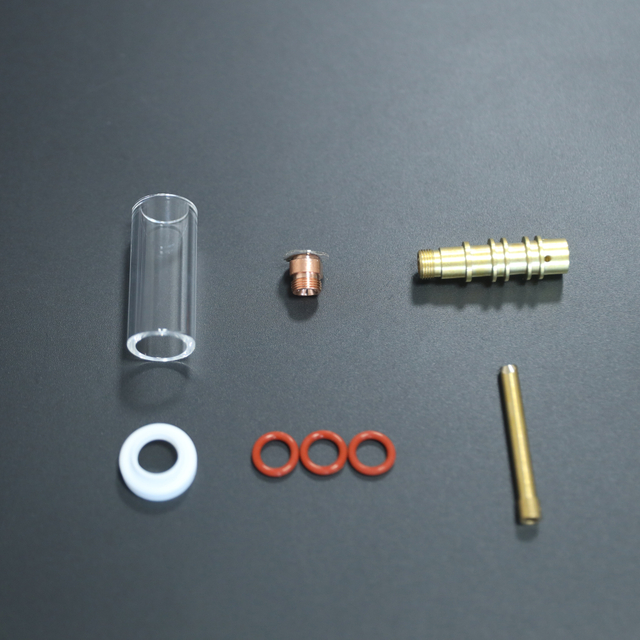

WP17/18/26 TIG Torch Kits

Complete accessory sets with gas lens and back caps.

Compatible with most TIG welders.

Includes ceriated tungsten electrodes for AC/DC use.

Essential TIG Consumables

Nozzles: Replace if cracked or deformed (typically every 40–60 welding hours).

Collets and Cups: Precision-fit for stable arc.

Gas Lenses: Improve gas coverage for better penetration.

FAQs on TIG Welding Accessories:

How often should I replace TIG torch nozzles? Replace if cracked or deformed (typically every 40–60 welding hours).

What tungsten electrode is best for stainless steel? 2% lanthanated for versatile AC/DC welding.

Check out our TIG Welding Accessories & Consumables for more details.

Plasma Welding Accessories

For cutting-edge plasma applications, our accessories provide superior conductivity and heat dissipation. Perfect for aerospace and medical device fabrication.

Key Plasma Consumables

Electrodes and Nozzles: High-purity copper for extended life.

Swirl Rings: Optimize plasma arc stability.

Shield Caps: Protect against molten splatter.

Frequently Asked Questions (FAQs) About Welding Accessories & Consumables

How to Select the Right MIG Torch?

Consider amperage rating, cooling method, and wire diameter compatibility. INWELT's series guide simplifies the choice.

Benefits of Quality Welding Accessories

Using premium consumables reduces defects, extends equipment life, and complies with industry standards like AWS and ISO.

What is used in welding torches?

Welding torches, commonly used in processes like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, rely on specific consumables. For MIG welding, a torch uses a consumable wire electrode and shielding gas (like argon or a CO2 mix). In TIG welding, the torch uses a non-consumable tungsten electrode, shielding gas, and sometimes a separate filler rod.

How do you calculate welding consumables?

To calculate welding consumables, you need to consider the weld length, joint type, and material thickness. For filler material, estimate the volume of the weld joint (cross-sectional area × length) and account for deposition efficiency (typically 60-90% depending on the process). For gases, calculate flow rate (e.g., liters per minute) multiplied by welding time. For electrodes, estimate the number based on weight per weld length and electrode size.

How do I choose welding consumables?

Choosing welding consumables depends on the base material, welding process, and desired weld properties. Match the consumable’s composition to the base metal (e.g., use stainless steel filler for stainless steel welding). Consider the welding method (MIG, TIG, or stick), joint design, and environmental factors like corrosion resistance or temperature. Always check manufacturer specifications for compatibility.

What is F number in welding consumables?

The F number (Filler number) is a classification used in welding to group filler metals and electrodes based on their usability and characteristics, as defined by the American Welding Society (AWS). For example, F numbers for electrodes in shielded metal arc welding (SMAW) range from F1 to F6, indicating the type of flux coating and welding position suitability.

What is the difference between consumable and non-consumable welding?

In consumable welding, the electrode or filler material melts and becomes part of the weld, as in MIG or stick welding. In non-consumable welding, the electrode doesn’t melt (e.g., tungsten in TIG welding), and a separate filler material may be added if needed. Consumable methods are faster for thicker materials, while non-consumable methods offer more precision for thinner or delicate materials.

How do you handle welding consumables?

Handle welding consumables with care to ensure quality welds. Store electrodes and filler wires in dry, temperature-controlled environments to prevent moisture absorption, which can cause weld defects. Use clean gloves to avoid contamination, follow manufacturer storage guidelines, and check for damage or expiration before use. For gases, ensure proper regulator settings and secure storage of cylinders.

How do I choose welding material?

Choosing welding material involves matching the filler metal to the base metal’s composition (e.g., carbon steel, aluminum, or stainless steel). Consider the welding process (MIG, TIG, etc.), mechanical properties like tensile strength, and environmental factors such as corrosion resistance. Refer to welding codes (e.g., AWS or ASME) and consult material compatibility charts for guidance.

Contact INWELT for Custom Welding Solutions

Ready to upgrade your welding setup? Contact our experts today for bulk orders, custom configurations, or technical advice. Follow us for the latest in welding technology and promotions.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių