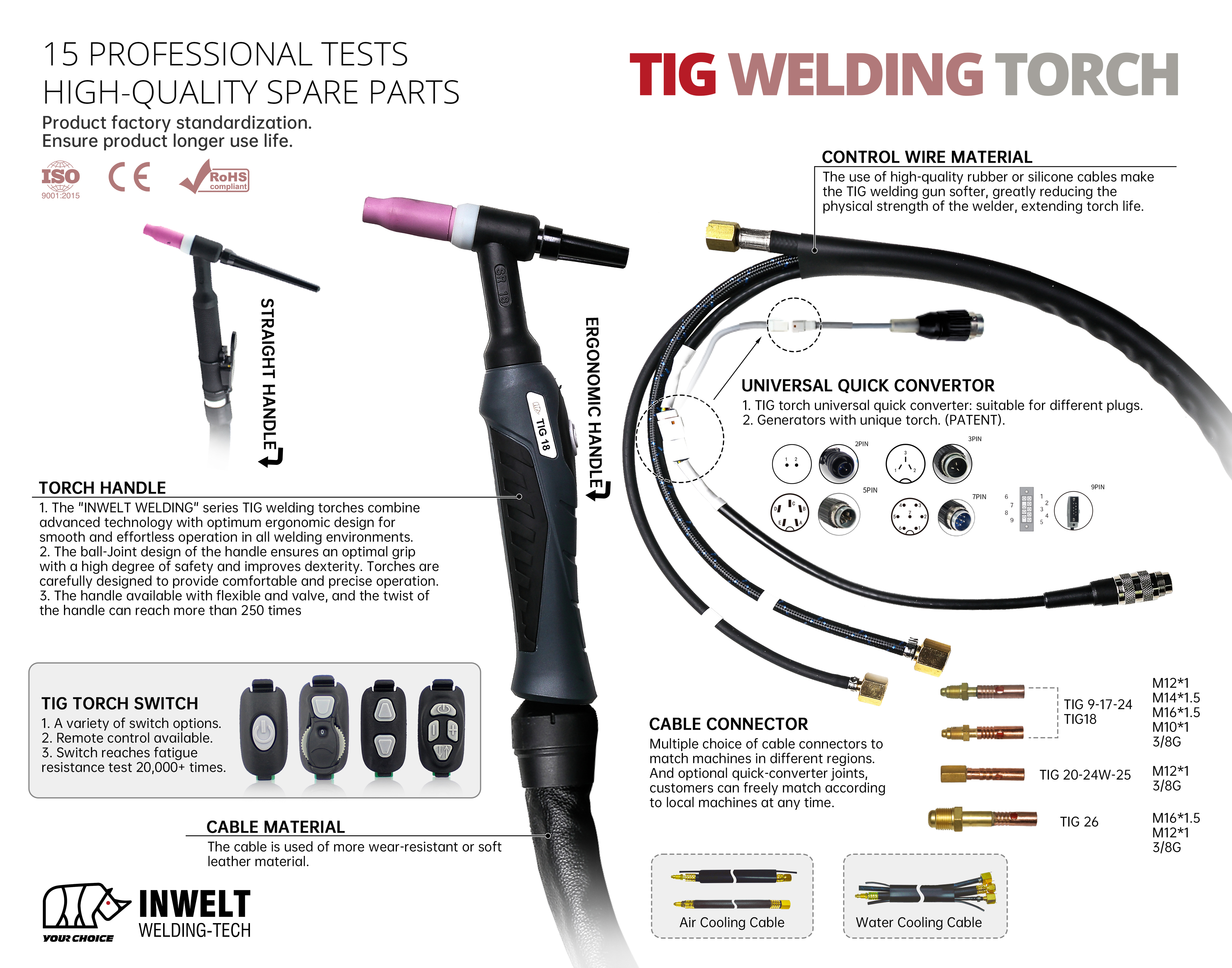

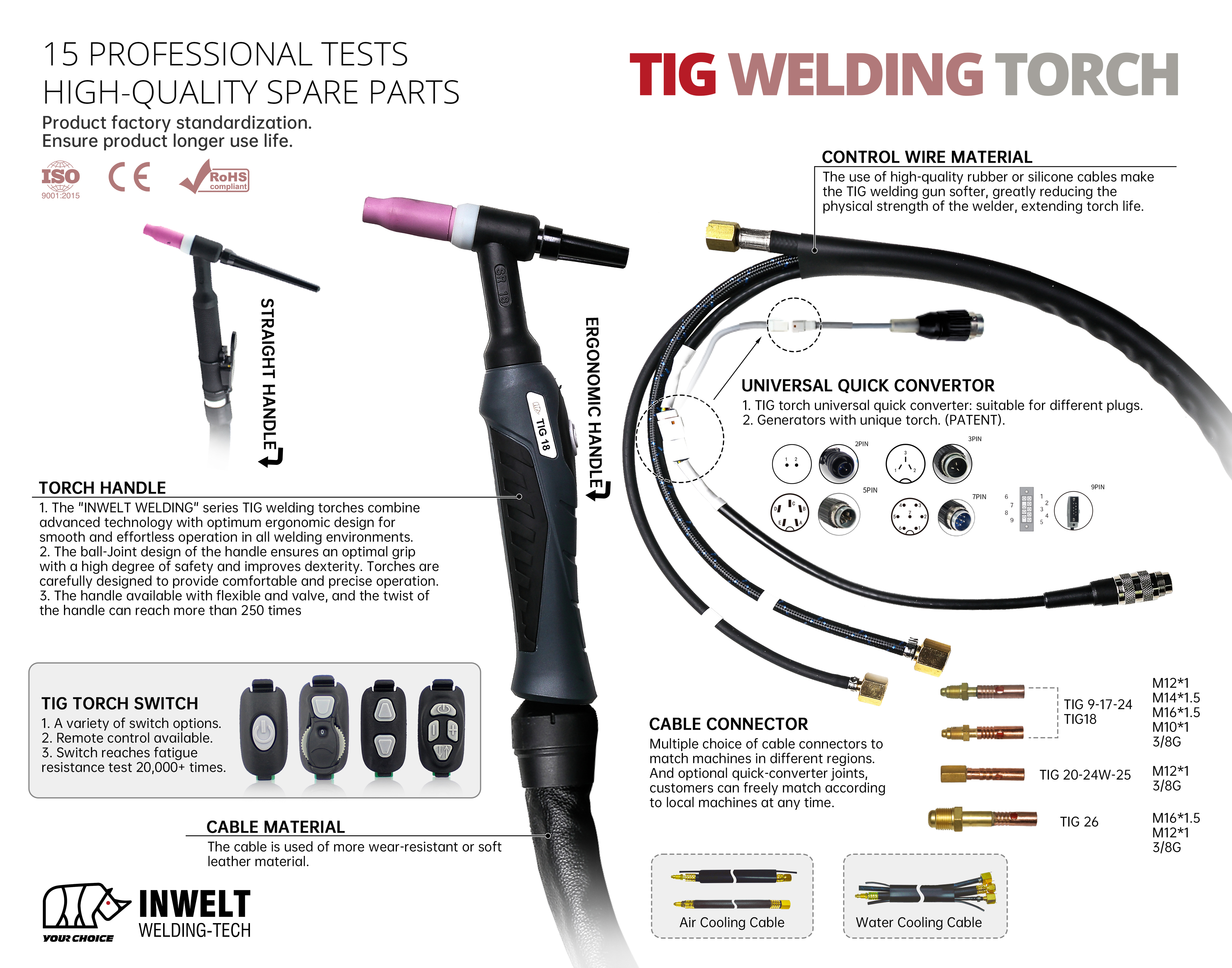

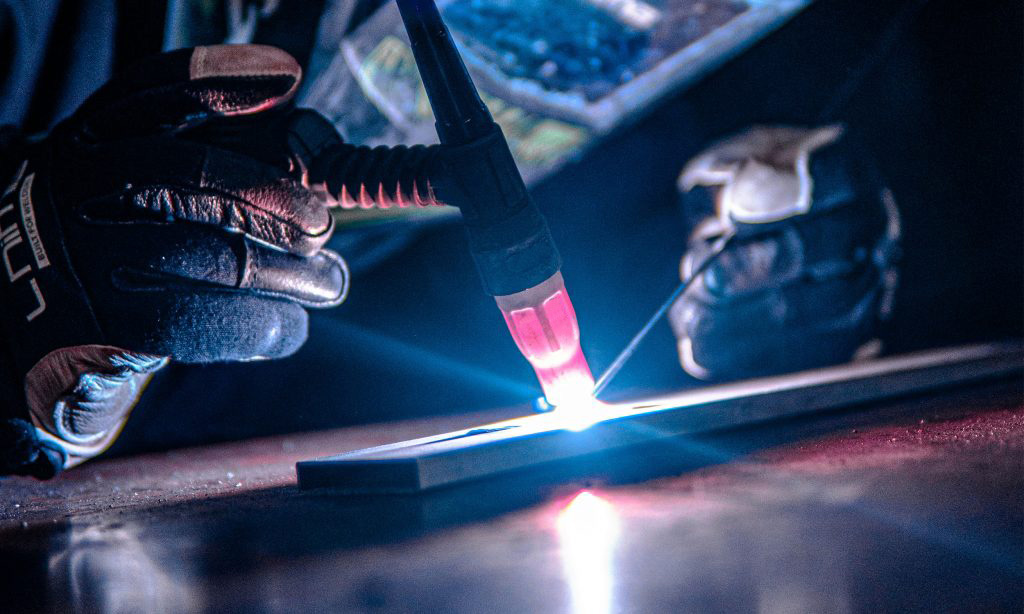

Light and Flexible TIG Welding INWELT line of tried and tested silicone rubber TIG torches are internationally compatible and designed for the best torch cooling technology.

TIG Welding Torch "SR" Style

SR TIG Torches GTAW

Modular, reliable TIG Torches for GTAW Welding

For welding alloyed steels, aluminum, magnesium, copper and their alloys, grey cast iron, bronzes, nickel, silver, titanium, lead, and unalloyed steels.

"SR" style TIG Torches from ABICOR BINZEL offer:

International standard cup and other TIG torch consumable parts

Modular design and build capabilities to meet the job requirements

Tried and trusted technology

Optimum torch cooling

Light and flexible cable assembly

E3® Electrodes for premium arc ignition and service life

Tungsten grinder and cutter accessories for exact electrode points during operation

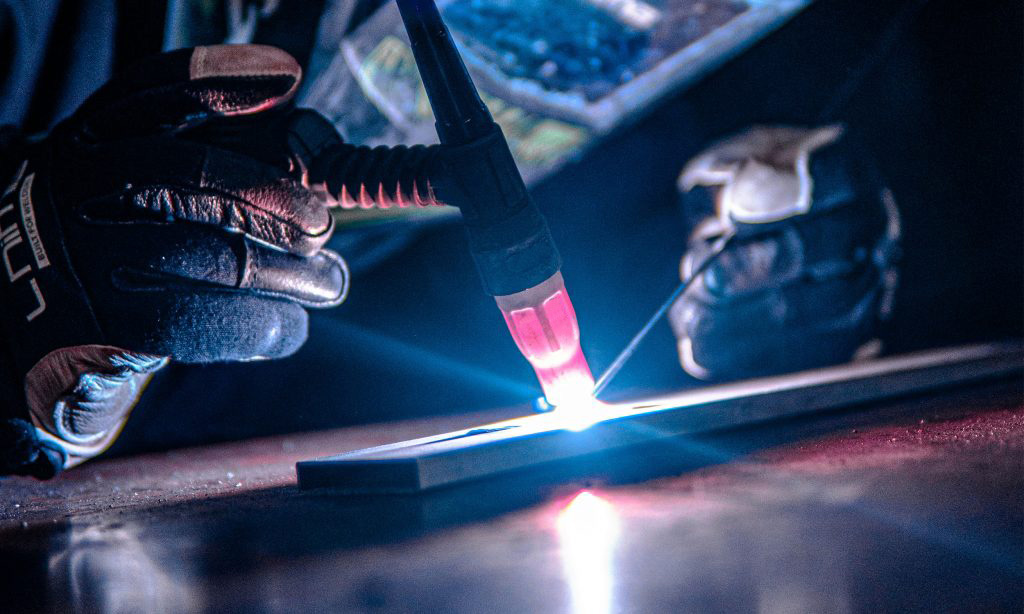

There are many types of TIG torches for different welding applications. TIG torch sizes vary greatly for different jobs. This article will help break down the basics for you when it comes to selecting your first torch. Depending on your amperage needs and your budget, there are always several good torch options for the beginner.

There are two main categories of TIG torches: Air/gas cooled and water cooled.

The main TIG torch types are detailed below.

Air Cooled TIG Torches

Air cooled TIG torches have only one hose input which is for gas. Therefore, Argon or Helium is shielding your weld puddle from external contaminants while the shielding gas is also cooling down the torch with its airflow.

There is debate as to whether these air cooled torches actually cool the torch effectively. They definitely aren’t as effective as water cooled, hence the lower amperage ratings on these torches. They take longer to cool, and cannot handle super high temperatures.

Due to the slower nature of the gas cooling process, these torches can overheat more easily than a water cooled torch setup. Air cooled torches are best for thinner walled materials and smaller hobby projects around the garage. However, the larger air cooled torches mentioned below can handle higher amperages if used properly.

Water Cooled TIG Torches

Water cooled TIG torches have three inputs with three respective hoses. There is the gas input for your shielding gas, a water input line, and a water outflow line.

Water cooled TIG torches have an advantage because they don’t overheat nearly as fast as air cooled torches. They can handle very high amperages, followed by a rapid cooling process.

Water cooled torches are ideal for professional TIG welders and fabricators. If you plan on TIG welding heavy walled materials on bigger projects, then a water cooled torch setup is worth looking into. Keep in mind that you must have a water cooler system for your welding machine in addition to your torch. These water coolers can get pricey, but they generally last a long time.

Air Cooled Torch Models

The gas/air cooled torches come in four main sizes.

A WP24 torch is a gas cooled torch capable of only 80 amps. It is compact but less common due to its limited amperage range – 80 amps will only handle very light TIG welding. However, this torch can fit in some super tight areas.

A WP9 torch is a gas cooled torch capable of 125 amps. It is compact but way more common, and can handle up to 1/8″ material. It can also fit into tight spaces.

A WP17 torch is a gas cooled torch capable of 150 amps. It is very popular with welders but it is more bulky. 150 amps can handle most standard weld joints – This torch is very well liked by fabricators.

A WP26 torch is the largest of the gas cooled torches – capable of 200 or more amps. It is used on very heavy walled alloys and is less common for everyday use among hobbyists.

WP9 and a WP17 gas cooled torches are the only torches with interchangeable gas thread inputs. They are female inputs and can be interchanged with the use of a male gas hose. The rest of the torches have their own types of threading, which can be confusing for beginners.

Water Cooled Torch Models

The water cooled torches come in two main sizes:

A WP20 is a water cooled torch that is the same size as the WP9 gas cooled torch. Being water cooled, it is capable of double the amperage of a WP9 torch. It can handle up to 250 amps

A WP18 is a water cooled torch capable of 350 amps. It is the heaviest duty torch most commonly produced. We use this in our shop for heavy walled aluminum and steel applications.

Torch Heads

The most common torch head is a “Rigid” model – which means its head (top of the torch) has no flexible capabilities for getting in tight spots. The angle that the torch head is set at cannot be moved to different positions. This is the most common type of model available in all torch numberings, and it is more cost friendly.

A “Flex Head” torch is a torch with a moveable head, so you can get into tight spaces and odd overhead joints. It is also just more ergonomic and allows for lots of adjustability. Flex heads will usually have “F” or “FX” next to the model number. Again, lower end torches usually don’t put these markings on any of their products.

Make sure you know if your torch is a flex head or a rigid head model. If you try to flex a rigid model, you’ll snap your torch in half!

Valves

When you are doing scratch start TIG, you have no option to control the gas with your foot pedal control. For more rudimentary processes like these, torch manufacturers introduced a valve feature which allows for manual gas control on the torch.

Before you strike your arc, you simply turn the gas on with a valve on your torches rear; and turn it off when you finish your bead. This feature allows you to conserve some argon without wasting your whole cylinder.

Torches with the valve feature usually have a “V” marking on the torch. However, the valve feature is always obvious because it protrudes from the back of the torch (it looks like a small dial).

Some torches will have different styles of valve mechanisms, but they all require a counter clockwise turn to get the gas flowing.

Amperage Control

The most common type of TIG amperage control is by using a foot pedal. These pedals send a signal to your machine to turn the gas and amperage on for your torch. They also signal when to stop the arc and start your post flow of gas. These are most common with high frequency start – A process where a high surge of amperage starts your TIG arc without having to scratch your tungsten on your material.

With TIG welding in the field, foot pedals can be a real pain. Because of this, there are mechanisms that allow you to control your amperage on the torch with your hand. These can be dials as well as pressure sensitive buttons.

These mechanisms will turn your gas and amperage on without a need for any pedal. They allow you to weld in different positions without worrying about using your feet.

Wrap Up

We hope this gave you a better idea on the types of TIG torches and what a setup involves. There are many options depending on what you plan on doing, and there are no rules – just guidelines.

You may find that you enjoy building small projects with light amperage TIG welding. Or, you may want to tackle big industrial projects. The good news is that there is a torch for everything.

Featured Image Credit : www.czinwelt.com – they make very high end TIG accessories that are worth checking out.

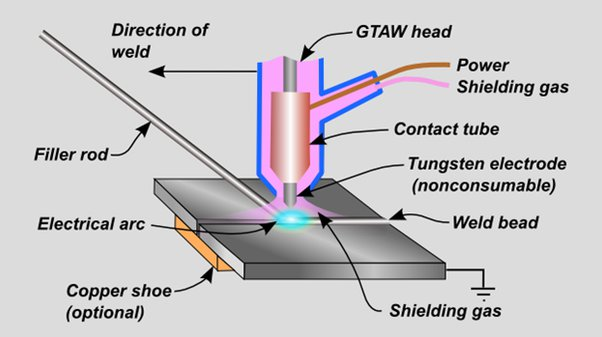

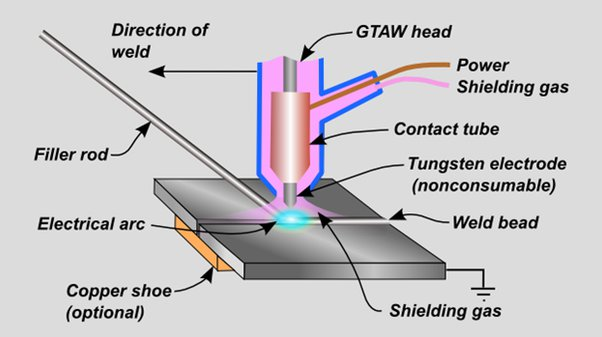

Tungsten Inert Gas

The electrode is tungsten metal. Shielding gas is helium or argon. Filler rod is usually similar to the base metal being welded. The concept is to keep the molten welding puddle from reacting with oxygen or nitrogen in the air. This produces a cleaner weld.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių