Ensuring Eye Safety in an Era of High-Precision Manufacturing

In the world of high-precision manufacturing, laser technology is a pivotal force, offering the ability to slice and fuse materials with unparalleled precision. With such formidable technology comes the imperative of meticulous safety practices, especially the protection of our vision. INWELT WELDING TECH, an expert in the field of welding torches, plasma cutters, and safety equipment, emphasizes the significance of fortifying our sight with dedicated vigilance.

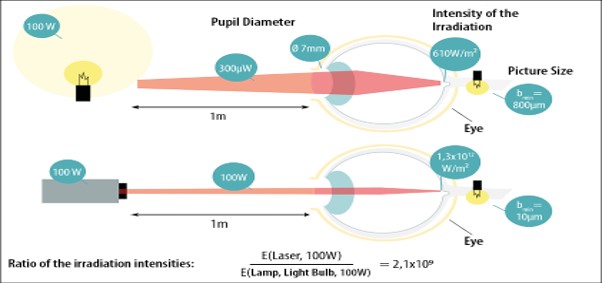

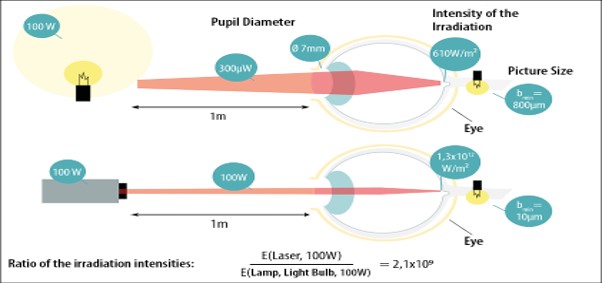

The Dangers of Laser Radiation

Laser beams, by their nature, concentrate radiation into a tight, coherent stream, unlike traditional light sources. The result is an energy density in the laser light that can cause permanent ocular or skin damage upon contact. To put it into perspective, when coherent light enters the eye, its energy density can be a colossal 2.1 billion times more intense than that of non-coherent light at the same energy level, illustrating the extreme risks posed by lasers.

How Your Eyes Are at Risk

Because many industrial lasers, like the Nd:YAG laser, emit light that's invisible and won't provoke a blink reflex, it's crucial to employ artificial means of protection. Laser welding and cutting safety goggles are indispensable for anyone in the vicinity of class 3R, 3B, or 4 lasers, with legal mandates in place for such protective measures.

The Lifespan of Safety Goggles

Laser welding and cutting safety goggles do have a finite service life, often spanning at least five years. Proper care can prolong their efficacy, continuing to shield your eyes over time.

Choosing Appropriate Safety Goggles

The selection process for safety goggles involves pairing the laser's specific characteristics with the goggles' protective features. They must defend against the laser's particular wavelength and operational mode, and offer adequate protection for the laser's power output.

Interpreting Goggle Markings

Safety goggles are marked with various symbols that inform the user of their specifications:

Numerical values (e.g., 180-350) indicate the wavelength range covered.

Letters denote the operation mode (D for continuous, I/R for pulsed, M for mode-locked).

LB ratings (e.g., LB 6) convey the protection level.

The manufacturer's identification is marked as PF.

An 'S' indicates the material's structural strength.

CE marking confirms compliance with European standards.

Understanding MPE and OD

The Maximum Permissible Exposure (MPE) and Optical Density (OD) are key indicators in the realm of laser safety. The MPE represents the highest level of laser radiation that can be endured without causing harm, typically capped at 2 mW for unprotected eyes. The OD value measures the level of absorption; for instance, an OD of 6+ signifies that the energy has been reduced by a factor of one million, lowering a 1000w beam to a safe 1mw.

The Value of Certification

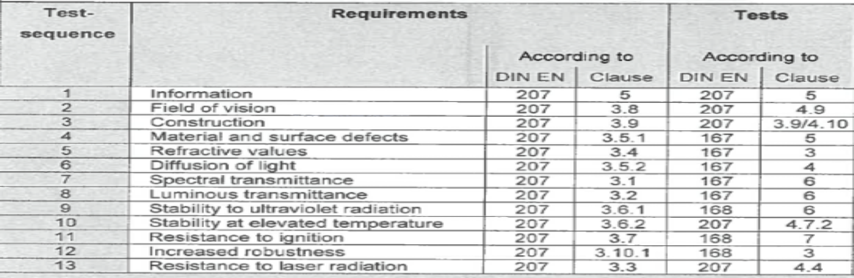

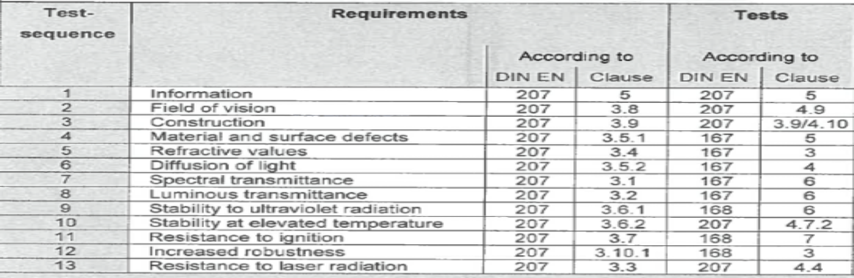

When considering the purchase of safety goggles, the choice between certified and non-certified options should be carefully made, bearing in mind the invaluable nature of one's vision. Certified goggles meet stringent standards, such as DIN EN 207, which assesses endurance against laser exposure and offers a reliable guarantee of safety beyond just OD values.

Standards for Safety Goggles

DIN EN 207 is pertinent to laser safety goggles, detailing protection levels from LB1 to LB10 based on the goggles' resilience to direct laser exposure for a specified duration or number of pulses. DIN EN 208 applies to goggles intended for alignment work with lasers, providing another layer of safety standardization.

The Role of High-Quality Materials in Safety Goggles

Selecting laser welding and cutting safety goggles crafted from superior materials is not a luxury—it's a necessity. High-quality materials ensure that the goggles not only absorb dangerous radiation but also withstand the test of time. Goggles from INWELT WELDING TECH are designed with robust substances that resist scratches and impacts, maintaining clarity of vision and structural integrity even in rigorous industrial settings.

Comfort and Compatibility

The effectiveness of safety goggles isn't just about protection—it's also about comfort and compatibility with other safety equipment. Comfortable goggles encourage consistent use, a non-negotiable factor in ensuring workplace safety. INWELT WELDING TECH's safety goggles are engineered to be lightweight and compatible with respirators and helmets, ensuring they can be worn for extended periods without causing fatigue.

Regular Inspection and Maintenance

To maintain the highest level of safety, regular inspection and maintenance of laser welding and cutting safety goggles are critical. Users should routinely check for any damage, such as cracks or deep scratches that could impede protection. Proper cleaning and storage are equally important to prevent damage. INWELT WELDING TECH provides guidelines and accessories to help users care for their safety goggles, ensuring long-term dependability.

Training and Awareness

While the right equipment is essential, the importance of training cannot be overstated. Workers must be thoroughly trained in the proper use and maintenance of safety goggles. INWELT WELDING TECH advocates for comprehensive training programs that equip workers with the knowledge to operate safely in environments where lasers are used.

A Final Word of Caution

In the dynamic world of laser technology, the stakes for eye safety are high. Choosing the correct laser welding and cutting safety goggles is not just a regulatory compliance issue but a safeguard against irreversible damage. INWELT WELDING TECH stands at the forefront of this protective battle, offering a range of certified goggles that meet and exceed the industry standards for laser safety.

Advanced Features of Laser Safety Goggles

When selecting laser welding and cutting safety goggles, it’s important to consider advanced features that enhance usability. INWELT WELDING TECH incorporates state-of-the-art design elements such as anti-fog coatings and ventilation systems to prevent the build-up of moisture, ensuring clear vision at all times. Additionally, the ergonomic design conforms to different face shapes, providing a secure fit that keeps the goggles in place during complex tasks.

The Spectrum of Protection

It's not only about the intensity of the laser; the spectrum of light that a laser emits is also of paramount concern. Safety goggles must offer protection across the necessary spectrum. INWELT WELDING TECH’s range covers a broad spectrum, ensuring users are shielded from ultraviolet, visible, and infrared radiation, tailoring protection to the specific lasers in use.

The Importance of Lens Quality

The lens quality in safety goggles is a critical factor that cannot be overlooked. Lenses must be free of imperfections to avoid diffraction or scattering of the laser beam, which could lead to inadvertent eye exposure. INWELT WELDING TECH ensures that each pair of safety goggles is equipped with high-grade optical lenses that provide clear and undistorted vision.

Considerations for Different Laser Types

Different laser applications require different types of safety goggles. For example, goggles used for cutting applications may need to withstand more intense radiation compared to those used for engraving. INWELT WELDING TECH offers a diverse selection of goggles, each optimized for specific laser types, whether for industrial cutting, medical applications, or research and development.

Compliance With Global Safety Standards

INWELT WELDING TECH's commitment to global safety standards is unwavering. Our safety goggles not only adhere to standards such as ANSI Z136 in the United States and DIN EN 207 in Europe but are also rigorously tested to comply with a variety of international protective regulations. This ensures that wherever your operations are based, our safety goggles provide the necessary level of protection.

After-Sale Support and Warranty

Understanding that after-sale support is crucial for customer satisfaction, INWELT WELDING TECH offers comprehensive after-sales service. This includes a warranty on our safety goggles, guaranteeing against manufacturing defects, and dedicated customer service to address any queries or concerns about our products.

Conclusion: A Vision of Safety

To sum up, the key to ensuring eye safety while performing laser welding and cutting lies in choosing the right protective gear. INWELT WELDING TECH’s laser welding and cutting safety goggles are engineered with precision, integrating comfort, durability, and compliance with international safety standards. By selecting our goggles, you're not just purchasing a product; you're investing in a culture of safety that protects your most valuable asset—your vision.

Integration of Technology in Safety Goggles

In this digital age, integrating technology into safety equipment is a trend that cannot be ignored. INWELT WELDING TECH is at the forefront of innovation, exploring ways to incorporate smart technology into laser welding and cutting safety goggles. Features like real-time alerts for radiation exposure and connectivity with other smart devices on the factory floor enhance safety protocols and ensure a cohesive protective environment.

Emphasis on User Education

Proper use of safety goggles extends beyond their physical application. INWELT WELDING TECH believes in empowering users through education. By providing comprehensive user manuals, online tutorials, and interactive training sessions, we ensure that individuals understand the importance of laser safety and the correct way to utilize their protective gear.

Customization Options

Recognizing that one size does not fit all, INWELT WELDING TECH offers customization options for its range of laser welding and cutting safety goggles. From adjustable straps and replaceable lenses to a variety of colors and designs, we accommodate the unique requirements and preferences of our clients. This ensures a more personal fit and encourages regular use, which is essential for effective protection.

The Role of Feedback in Product Development

Feedback from users plays a crucial role in the continuous improvement of safety goggles. INWELT WELDING TECH values customer insights and actively seeks out feedback to drive product development. This collaborative approach results in safety goggles that are not only technically advanced but also refined to meet the practical needs of end-users in the field.

Aligning with Industry Trends

The laser industry is ever-evolving, and staying current with its trends is vital. INWELT WELDING TECH’s product development team keeps a pulse on the latest advancements in laser technology to ensure that our safety goggles meet the demands of new and emerging applications. We are committed to innovation that matches the pace of the industry while maintaining the highest safety standards.

Environmental Considerations

Sustainability is increasingly becoming a priority in the manufacturing of safety equipment. INWELT WELDING TECH is dedicated to reducing the environmental impact of our products. Our safety goggles are made with recyclable materials wherever possible, and we implement eco-friendly practices throughout our manufacturing process to minimize our carbon footprint.

Final Thoughts on Safety Goggles

Laser welding and cutting operations are integral to modern manufacturing, and so is the need for reliable safety goggles. INWELT WELDING TECH's laser welding and cutting safety goggles represent the pinnacle of protection, comfort, and technological integration. By choosing our products, you are choosing to prioritize the well-being of your workforce and the quality of your operations.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių