Environmental Protection Fume Extraction Welding Torch

The design of collection systerm is integrated on the welding body, high negative pressure is usded to absorb and discharge welding dust(potratly dust purfier is required).

Long term protection of weldier respiratory system, reduce environmental pollution, more healthy and more environmentally friendly choice.

Specification

| Protective Gas Type | 340A CO2/ 290A Mix |

| Test Gas Flow | 10-25L/min |

| Welding Method | MIG/MAG Welding |

| Length | 3m 4m 5m or customized |

| Rated Load Duration | 60% |

| Guiding Method | Manual |

| Voltage Rating | ≤113V |

| Rear Interface | Euro Type |

| Certification | CE |

| Type | MIG Welding Torch |

The torch is connected to the welding machine or control device. With different diameters of welding wire and contact tip, MIG/MAG welding can be done by protective cooling gas CO2 or mix air.

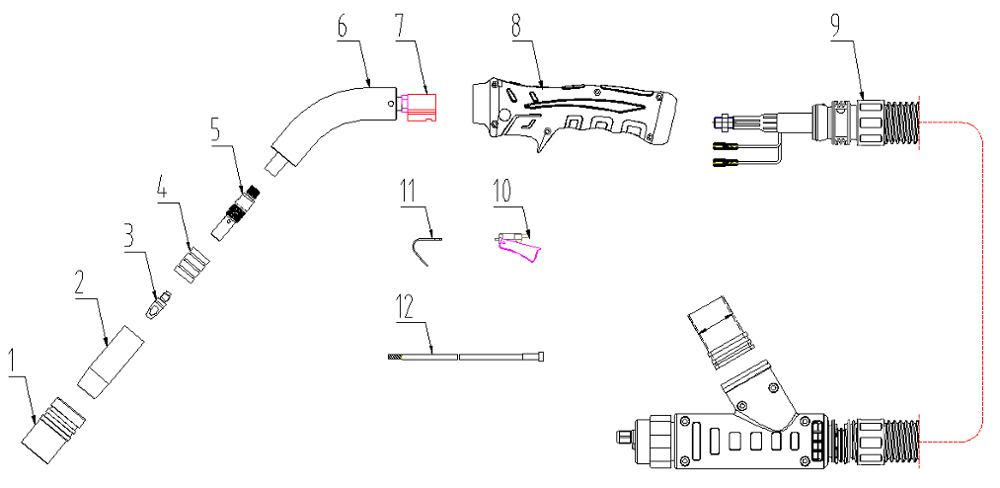

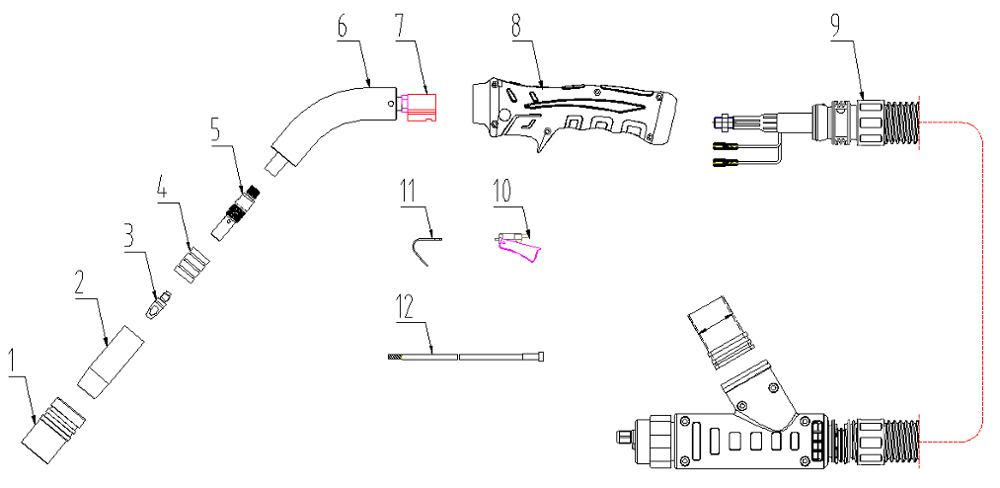

Welding Torch Structure Diagram and List:

| Position | Code | Ref. | Description |

| 1 | UDT0668 |

| Conical nozzle/fume extraction/GF351/8 HOLES |

| 2 | UDT0661 |

| Gas nozzle/GF351/Φ15mm |

| 3 | IJDV0015-12 |

| Contact tip/Φ1.2mm E-CU/M8*30 |

| 4 | IJDL0697 |

| Insulator 34A |

| 5 | IJDG0004 |

| Diffuser/GF351/M8 |

| 6 | IJDA0615 |

| Felix torch head/GF351/M10*1 |

| 7 | IJGU8217 |

| Hook up/Q235/extractione welding torch |

| 8 | IJIR0081 |

| Trigger red |

| 9 | IJDW0079 |

| Torch handle/black/pa66+30%gf/extractione welding torch |

| 10 | IJIK0147 |

| Joint with hole/black/pa66+30%gf/extractione welding torch |

| 11 | IJD00535 |

| Cable assembling 25MMQ/3M |

| 11.1 | IJAI0801 |

| Torch head tube/GF351/Φ27 |

| 12 | IJIK0972 |

| Back box hole/blackpa66+30%gf/extractione welding torch |

| 13 | IJIK0081 |

| Gun plug nut |

| 14 | IJUC0060 |

| Euro central adapter body/spring pins |

| 15 | IJJD0571-02 |

| Insulated steel liner/Φ1.0-1.2mm/3m RED/torch |

| 16 | IJDH6011 |

| Spanner for MIG |

|

| Complete Torch |

| IJDUF2909 |

| MIG GF351 TORCH 3M WITH SPRING PINS/FUME EXTRACTION |

| IJDUF2900 |

| MIG GF351 TORCH 4M WITH SPRING PINS/FUME EXTRACTION |

| IJDUF2906 |

| MIG GF351 TORCH 5M WITH SPRING PINS/FUME EXTRACTION |

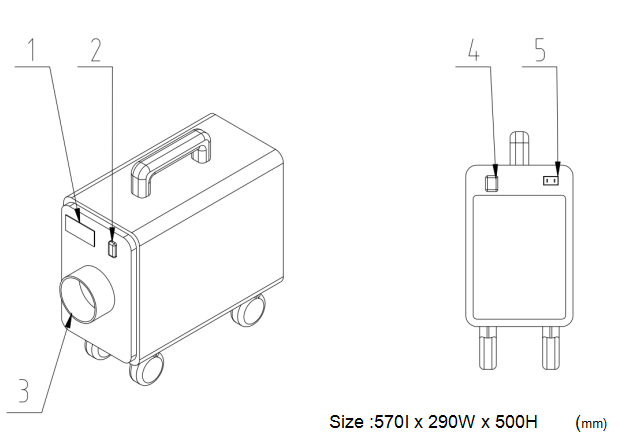

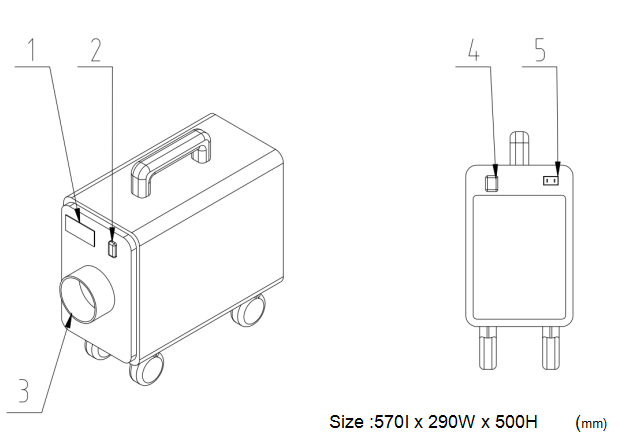

SFPG-20A

| Inspiratory Air Volume (m3/h) | 200±10 | Total Filtration Area (m2) | 6 |

| Motor Power (Kw) | 0.8 | Compressed Air (Mpa) | 0.5-0.6 |

| Fan negative Pressure (Pa) | 23000 | Gray drum Volume (L | 5 |

| Noise (dB)(A) | ≤70±5 | Cleaning Method | Automatic Cleaning |

| Voltage (V/Hz) | 220/50 | Control Section | Delixi Electric |

| Equipment Dimensions (mm) | 570L x 290W x 500H | Equipment Weight (Kg) | 25±5 |

| Number of Filter Cartridges | 1 | Filtration Area (m2) | 6 |

| Filter Material | Polyester + Microporous Film | Filter Cartridge Size | 200x170 |

Structure Chart and List:

| SN. | Number | Part Name | Quantity |

| 1 | \ | Display panel | 1 |

| 2 | \ | Switch button | 1 |

| 3 | \ | Air duct interface | 1 |

| 4 | \ | Switch | 1 |

| 5 | \ | Power input interface | 1 |

Welding Fume Extraction Gun Can Be Efficiently Protect Welders Risk from Welding Fumes

The Risk of Harmful Welding Fumes

As people concerns, during the welding , welders will face the risk of harmful welding fumes. The awareness of the risk and illness has increased and then New Regulations and Obligations for employers have come into force. People no longer ignored the risk .

Inwelt Fume Extraction Gun Protect Welders for Health and Hetter Life

All the welders are started to looking for health and better life. The great news is Inwelt awareness and concerns welders health risk. With an Inwelt fume extraction gun, the welding fume are collected directly from the nozzle during the during welding. By this way, it provide the safe working environment for welder and entire team.

Optimal Fume Extraction for a Safer Workspace

The INWELT FE340 Fume Extraction MIG Welding Gun is a state-of-the-art fume extractor designed to significantly reduce welding fume exposure, ensuring a safer and cleaner working environment. By integrating an advanced fume extraction system directly into the welding torch, the FE340 targets and removes hazardous fumes right at the source, protecting welders from the health risks associated with welding emissions.

High-Efficiency Welding Fume Extractor

As an industry-leading welding fume extractor, the FE340 boasts a high negative pressure system that is adept at capturing and channeling welding dust through the torch body, requiring only a compatible dust purifier for complete fume management. This focus on health through technology makes the FE340 an essential tool for any welding professional looking to prioritize respiratory health and workplace safety.

Ergonomic Design and Versatility

The ergonomic design of the FE340 Fume Extraction MIG Welding Gun from INWELT WELDING TECH ensures that users can handle their welding tasks with ease and comfort. Available in various lengths—3m, 4m, and 5m—and compatible with wire sizes ranging from Φ0.8-1.2mm, this fume extractor is versatile and suitable for a wide array of welding operations. Its gas-cooled system and impressive duty cycle of 60% at 340Amp with CO2 and 290Amp with mixed gases assure consistent performance and reliability.

Compliant with Safety Standards

Compliance with safety regulations is more than a commitment; it is a necessity. The FE340 welding fume extractor not only meets but exceeds expectations by adhering to CE certification standards. By incorporating this fume extraction product into your welding processes, you align with the latest safety protocols and ensure a healthier working environment for all.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių