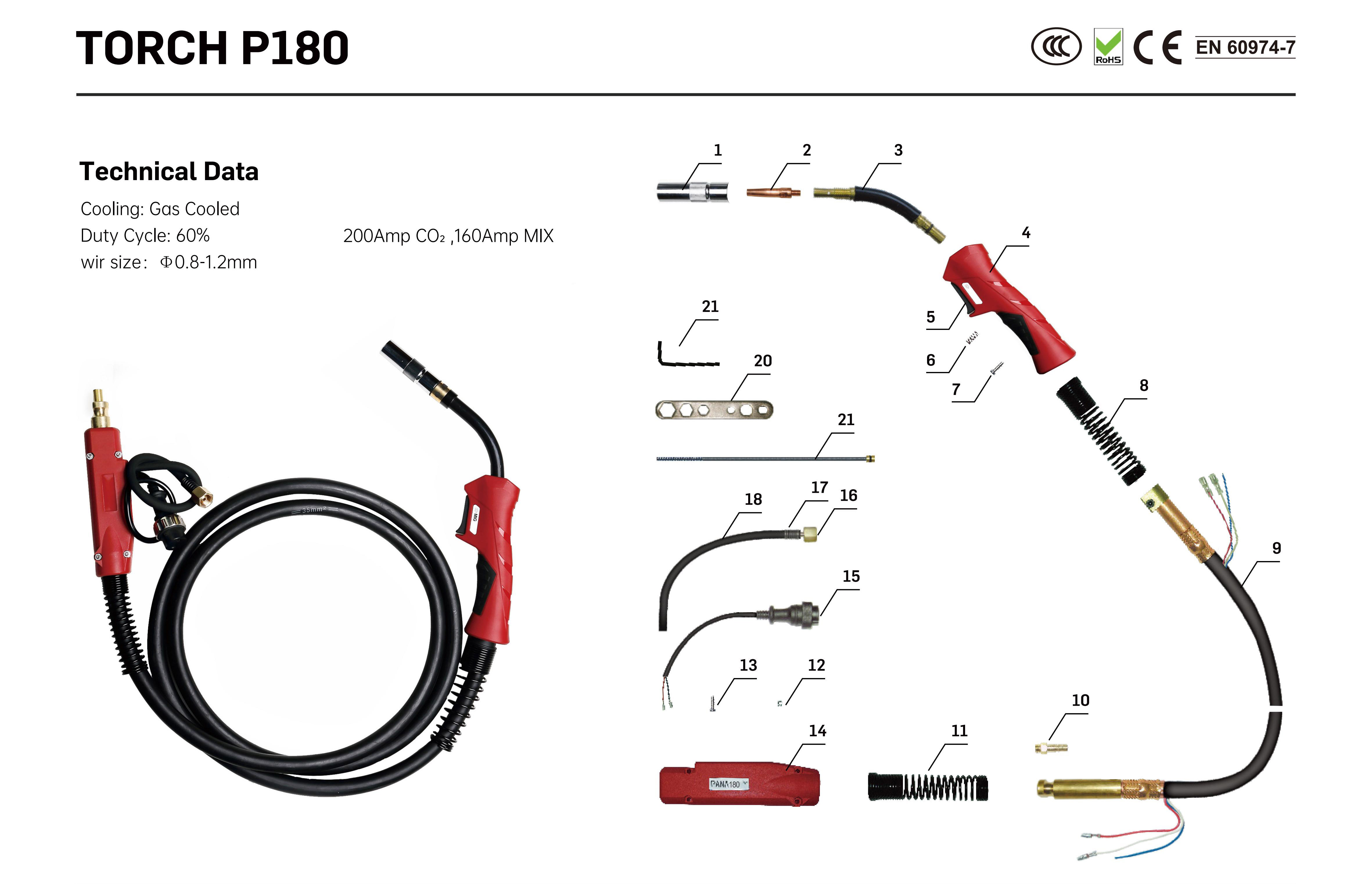

INWELT P180 Gas-Cooled CO2 MIG Welding Gun: Precision & Durability for Professional Welders

The INWELT P180 Gas-Cooled CO2 MIG Welding Gun is more than just a tool; it's a commitment to efficiency and comfort. Recognizing the physical demands of heavy-duty welding, Inwelt has incorporated an ergonomically designed, fully insulated Nylon handle. This feature significantly reduces operator fatigue, allowing welders to maintain focus and precision even during prolonged work sessions. By using only quality raw materials and employing advanced production and testing equipment, Inwelt ensures that every P180 torch meets stringent quality standards, providing welders with a reliable and long-lasting piece of equipment.

Key Features & Unparalleled Benefits

The INWELT P180 MIG Welding Gun stands out in the market due to its thoughtful design and superior construction. Every feature contributes to a better welding experience, from initial setup to the final weld.

Robust & Ergonomic Design for Operator Comfort

The P180 features a fully insulated Nylon handle that is not only robust but also ergonomically shaped to fit comfortably in the welder's hand. This design significantly reduces operator fatigue, allowing for longer, more productive welding periods. The durability of the handle ensures it can withstand the rigors of heavy-duty work environments, providing a secure grip and protection.

Superior Material Quality & Manufacturing Precision

Inwelt's commitment to quality starts with the selection of raw materials. The P180 is constructed from high-quality components, ensuring excellent conductivity, heat resistance, and overall longevity. Coupled with advanced production and rigorous testing equipment, every torch is manufactured to precise standards, guaranteeing consistent performance and reliability right out of the box.

Seamless Compatibility & Easy Installation

The P180 welding gun is designed for universal appeal. It is compatible with a wide array of MIG welding machines that utilize a Europe socket or Panasonic interface. This adherence to standard model sizes ensures easy and quick installation, minimizing downtime and maximizing productivity. Whether you're upgrading an existing setup or integrating into a new system, the P180 offers hassle-free connectivity.

Versatility for Diverse Welding Applications

From thin sheet metal to thicker plates, the P180 is built to handle a variety of welding tasks. Its optimized design ensures versatile performance, meeting the needs of numerous applications across different industries. This adaptability makes it an invaluable tool for workshops handling diverse projects.

Technical Data:

Current | 200Amp CO2, 160Amp MIX

| Gas Flow |

|

Duty Cycle | 60%

| Ignition |

|

Gas | Gas Cooled

| Post flow |

|

Wire Size | 0.8-1.2mm

| Standard Length | 3m 4m 5m

|

Technical Specifications: Powering Your Welds

Understanding the technical data of the INWELT P180 provides insight into its capabilities and suitability for various welding tasks.

Current Rating:

Duty Cycle: 60% - This means the torch can operate at its maximum rated current for 6 minutes out of every 10-minute period. A 60% duty cycle is excellent for professional use, allowing for sustained welding without frequent cooling breaks, thus increasing productivity.

Cooling Method: Gas Cooled - This air-cooled design is simple, effective, and requires no external cooling systems, making the torch highly portable and easy to maintain. The shielding gas itself helps cool the torch components.

Wire Size Compatibility: 0.8mm - 1.2mm - The torch supports a common range of welding wire diameters, offering flexibility for different material thicknesses and weld requirements.

Standard Lengths: Available in 3m, 4m, and 5m cable lengths, providing options to suit various workspace sizes and application needs, from small workshops to large industrial settings.

Understanding the Importance of Duty Cycle

The 60% duty cycle of the P180 is a crucial specification for professional welders. It signifies the torch's ability to maintain high output for extended periods without overheating. For comparison, a lower duty cycle (e.g., 35% or 40%) would require more frequent breaks for the torch to cool down, slowing down production. The P180's robust duty cycle ensures consistent performance even during demanding, repetitive welding tasks.

Optimizing Wire Feed and Gas Flow

The P180's design ensures optimal wire feeding for the specified 0.8-1.2mm wire sizes. Proper tension and liner selection are vital for smooth feeding, preventing bird-nesting and ensuring a consistent arc. The gas-cooled design relies on the shielding gas flow to dissipate heat, making it crucial to set the correct gas flow rate for both effective cooling and proper weld puddle protection.

Versatile Application Areas

The INWELT P180 Gas-Cooled CO2 MIG Welding Gun is a highly versatile tool, making it suitable for a broad spectrum of industries and applications. Its robust performance and adaptability ensure it can handle diverse welding challenges.

General Engineering: Ideal for workshops and fabrication shops handling a variety of metal projects, from light repair work to custom component manufacturing.

Construction Industries: Excellent for on-site fabrication and repair of structural steel, rebar, and other metal components required in building and infrastructure projects.

Power Cycle: Suitable for maintenance and repair of components in power generation facilities, where consistent and reliable welds are critical.

Railway Industries: Useful for fabricating and repairing parts for railway tracks, rolling stock, and associated infrastructure, demanding robust and durable equipment.

Heavy-Duty Industry: Capable of handling the rigorous demands of heavy machinery manufacturing, shipbuilding, and other high-stress industrial environments.

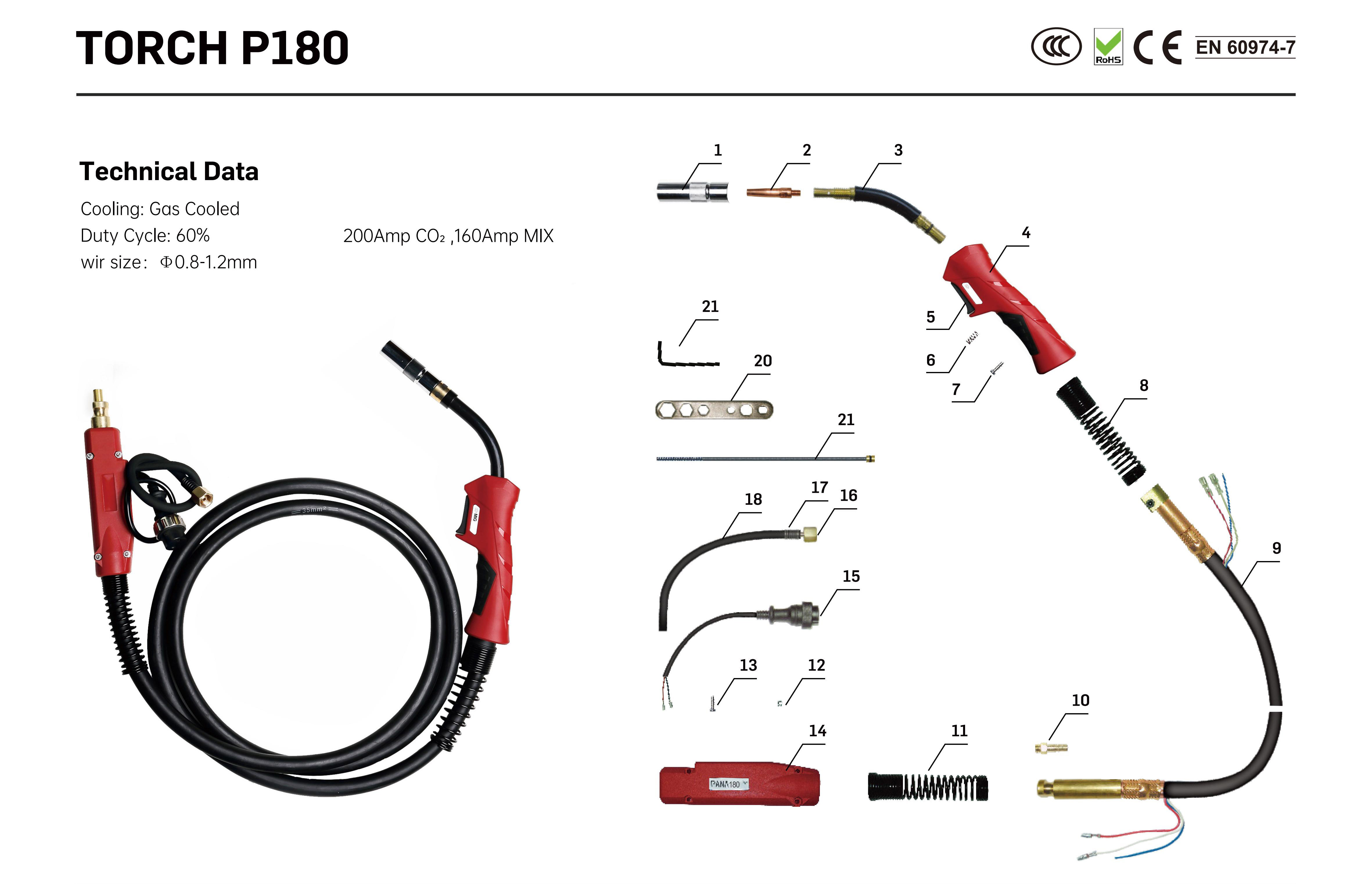

Spare Parts Details:

| Position | Code | Ref. | Description |

| 1 | IJDT0467 | 145.0100 | Nozzle PAN 180 |

| 2 | IJDV0757-10 | 140.0242 | Contact tip Φ0.8mm E-CU/ M6x45 |

| 3 | IJDA0751 | 142.0001 | Torch head PAN 180 |

| 4 | IJDW0806-01 | 004.0012 | MIG handle PAN180 |

| 5 | IJIR0197 | 003.0013 | Switch for MIG/PAN |

| 6 | IJGU0871 | 400.0044 | Spring for switch/PAN |

| 7 | IJGU0885 |

| Screw M3X8mm |

| 8 | IJGU0836 | 185.0031 | Spring cable support |

| 9 | IJD00110-01 |

| Coaxial cable assembling /3m/PAN |

| 10 | IJAI7076 |

| Gas connector for MIG torch/PAN |

| 11 | IJGU0832 |

| Spring cable support/PAN |

| 12 | IJGU0031 |

| Nut M4 |

| 13 | IJGU0080 |

| Screw M4x20 |

| 14 | IJIK0704 |

| Back box for PAN torch |

| 15 | IJIR0760 |

| Connector 2 holes/with connectors/PAN |

| 16 | IJAU9010 |

| Connector with hexagonal nut 9/16-18 |

| 17 | IJGU0814 | 501.2155 | Spring for gas tube |

| 18 | IJLI0679 | 501.0082 | EPDM tube 4.8x10M |

| 19 | IJJD0562 |

| Insulated steel liner Φ0.8-1.0mm/3.1m/Black PAN180 |

| 20 | IJDH6011 | 126.0021 | Spanner for MIG torches |

| 21 | IJDH6018 | 124.0026 | Spanner for PAN torch |

|

| Complete Torch |

| JDU6542-36 |

| MIG 180 torch 3m PAN |

| JDU6543-36 |

| MIG 180 torch 4m PAN |

| JDU6544-36 |

| MIG 180 torch 5m PAN |

Our Catalog:

INWELT MIG WELDING TORCH.pdf

INWELT MIG WELDING TORCH.pdf

FAQ:

1. What is the maximum current capacity of the P180 MIG Welding Gun?

The P180 is rated for 200 Amps when using CO2 shielding gas and 160 Amps with MIX gas, both at a 60% duty cycle.

2. Is the P180 compatible with all MIG welding machines?

The P180 is designed for compatibility with MIG welding machines that feature a standard Europe socket or Panasonic interface.

3. What wire sizes can the P180 welding gun accommodate?

The P180 is compatible with welding wire sizes ranging from 0.8mm to 1.2mm.

4. What lengths are available for the P180 welding gun's cable?

The P180 is available with standard cable lengths of 3 meters, 4 meters, and 5 meters.

5. Is the P180 suitable for heavy-duty industrial welding?

Yes, with its robust design, 60% duty cycle, and high current capacity, the P180 is well-suited for heavy-duty industrial applications, including construction, railway, and general engineering.

6. What kind of cooling does the P180 use?

The P180 is a gas-cooled torch, meaning the shielding gas flowing through the torch helps dissipate heat during operation.

7. How does the ergonomic handle benefit the welder?

The ergonomic, fully insulated Nylon handle is designed to reduce operator fatigue and provide a comfortable grip, enabling longer and more precise welding sessions.

8. Are spare parts readily available for the P180?

Yes, a detailed list of spare parts for the P180, including contact tips, nozzles, and liners, is available to ensure easy maintenance and repair.

9. Can I request a sample of the P180 before making a bulk purchase?

Yes, China Inwelt offers product samples, typically for a reasonable charge, allowing you to evaluate the P180's quality and performance.

10. Does China Inwelt offer customization services for the P180?

Yes, we provide OEM/ODM services to meet specific customization and private labeling requirements for the P180 MIG welding gun.

Why Choose China Inwelt for Your Welding Needs?

Choosing a reliable supplier is as important as choosing the right equipment. China Inwelt is dedicated to providing high-quality welding solutions and exceptional customer service.

Unwavering Quality Control

At China Inwelt, quality is paramount. We implement stringent quality control measures throughout our manufacturing process, from raw material inspection to final product testing. Our engineers provide technical support and oversight to ensure every P180 welding gun meets the highest industry standards, guaranteeing reliability and consistent performance.

Comprehensive Customer Support & Partnership Programs

We believe in fostering strong, long-term relationships with our clients and partners.

Sample Availability: We offer product samples (with reasonable charge) allowing you to test the P180's performance and quality firsthand before making a larger commitment.

OEM/ODM Services: For businesses requiring customized products or private labeling, Inwelt provides comprehensive OEM/ODM services, tailoring solutions to your specific branding and technical requirements.

Distributor Benefits: We offer special discounts and marketing protection to our valued distributors, providing a competitive edge and support for growth in their respective markets.

Flexible Shipping Solutions: We understand diverse logistical needs. We accept mixing various items in 40 Feet High Cube and 20 Feet containers, offering flexibility and efficiency for your shipping arrangements.

Factory Visits: We welcome potential clients to visit our manufacturing facilities. Witness our production processes, quality assurance protocols, and meet our dedicated team to gain complete confidence in our capabilities.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių