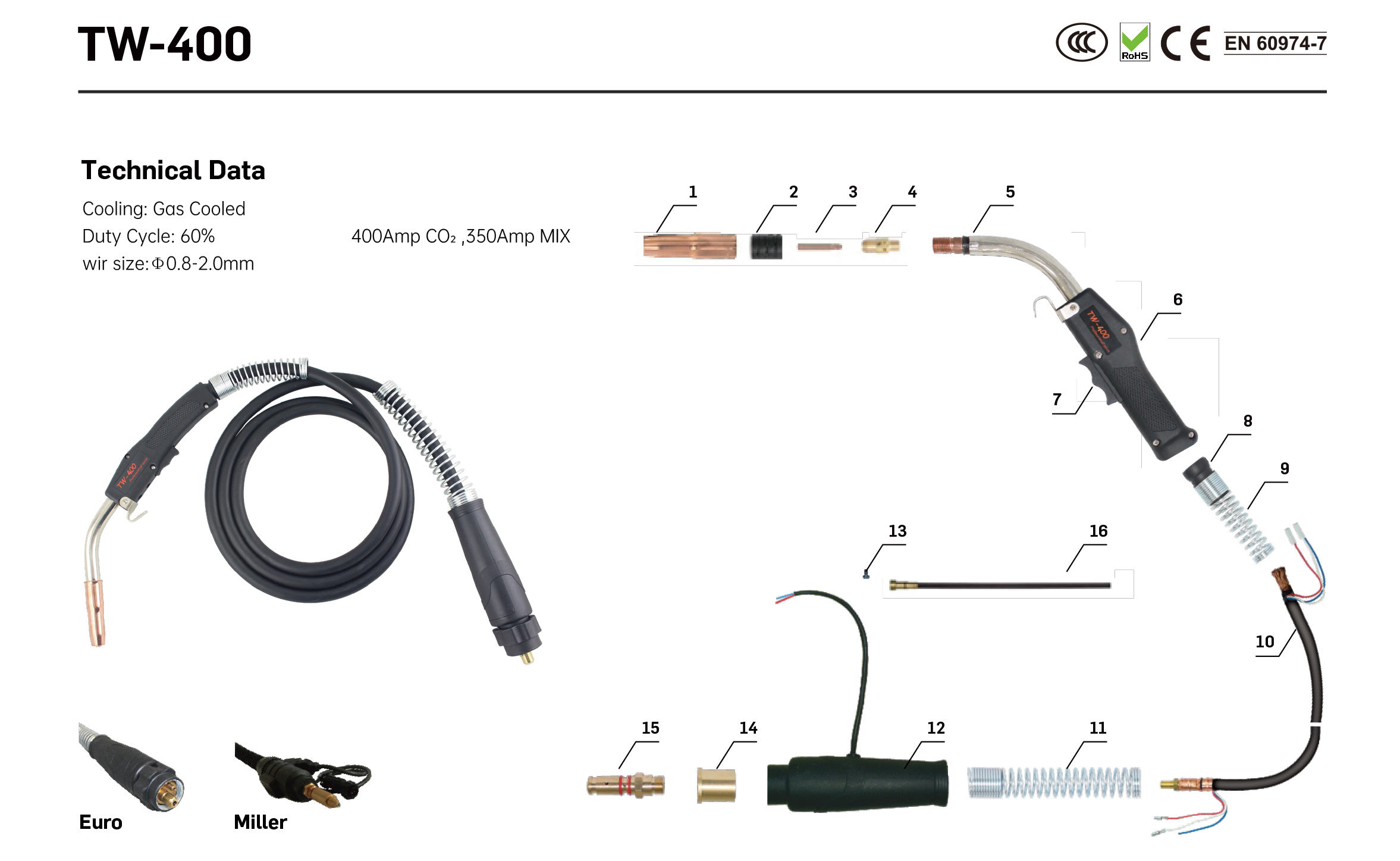

TW400 Gas Cooled Mig Welding Torch

The "INWELT WELDING TECH” TW400 Air-Cooled MIG Welding Torch is a classic Tweco Series air-cooled MIG welding torch rated at 400 amps at a 60% duty cycle.

The whole gun adopts an interlocking handle design with excellent toughness, a more comfortable pulling angle trigger, higher impact-resistant materials, and a comprehensive ergonomic design concept.

"INWELT WELDING TECH” also offers a complete stock of consumables and spare parts for the Tweco range of MIG Welding Guns

TW400 Features & Benefits:

The TW series MIG Welding Torches are the High-quality 250Amp (60% duty cycle) MIG guns. Suitable for most farm, shop, and home projects, heavy repairs, maintenance, and auto body work applications

Consumables are compatible with Lincoln and Tweco Series Nozzle, and Contact Tips

Durable Housing: With rubber and nylon casing for better hand-feel, durability, and stability.

Ergonomic Design: Non-slip, comfortable, and safe. Equipped with a high-quality phosphor bronze switch for extra strength and durability.

Upgraded Nozzle: Seamless thickening design, made with sufficient premium materials. Exquisite workmanship.

Solid Material: This welding torch with pure copper joints and oxygen-free super flexible mono cable for welding safety. CNC integrated processing, optimal pure brass copper.

Premium Cable: MIG CO2 Gas Shielded Welding Torch, featuring tensile, anti-wear, anti-corrosion, lightweight, and soft.

Adapt to miller, euro, tweco, lincoln, tregaskiss, panasonic connections.

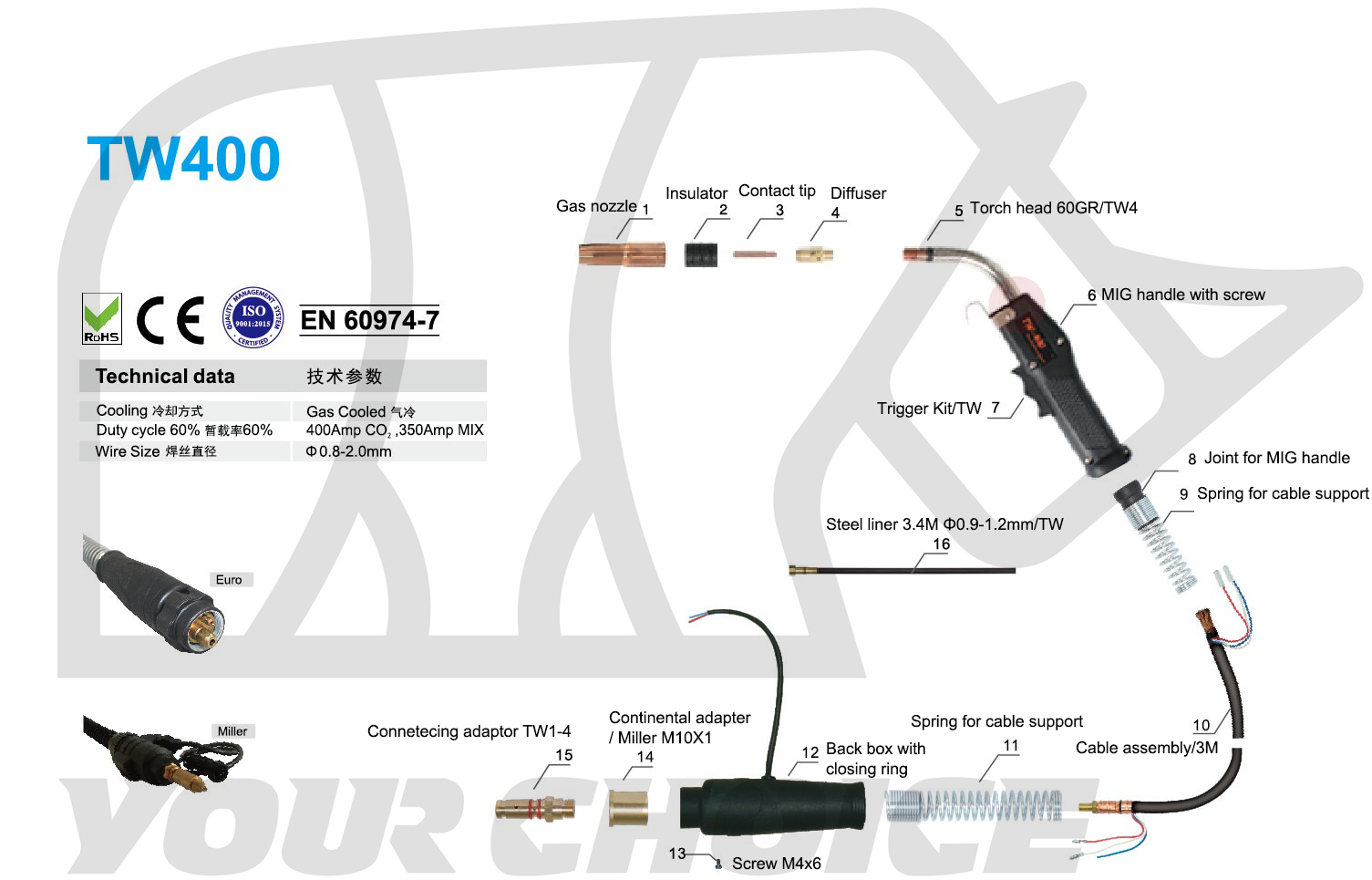

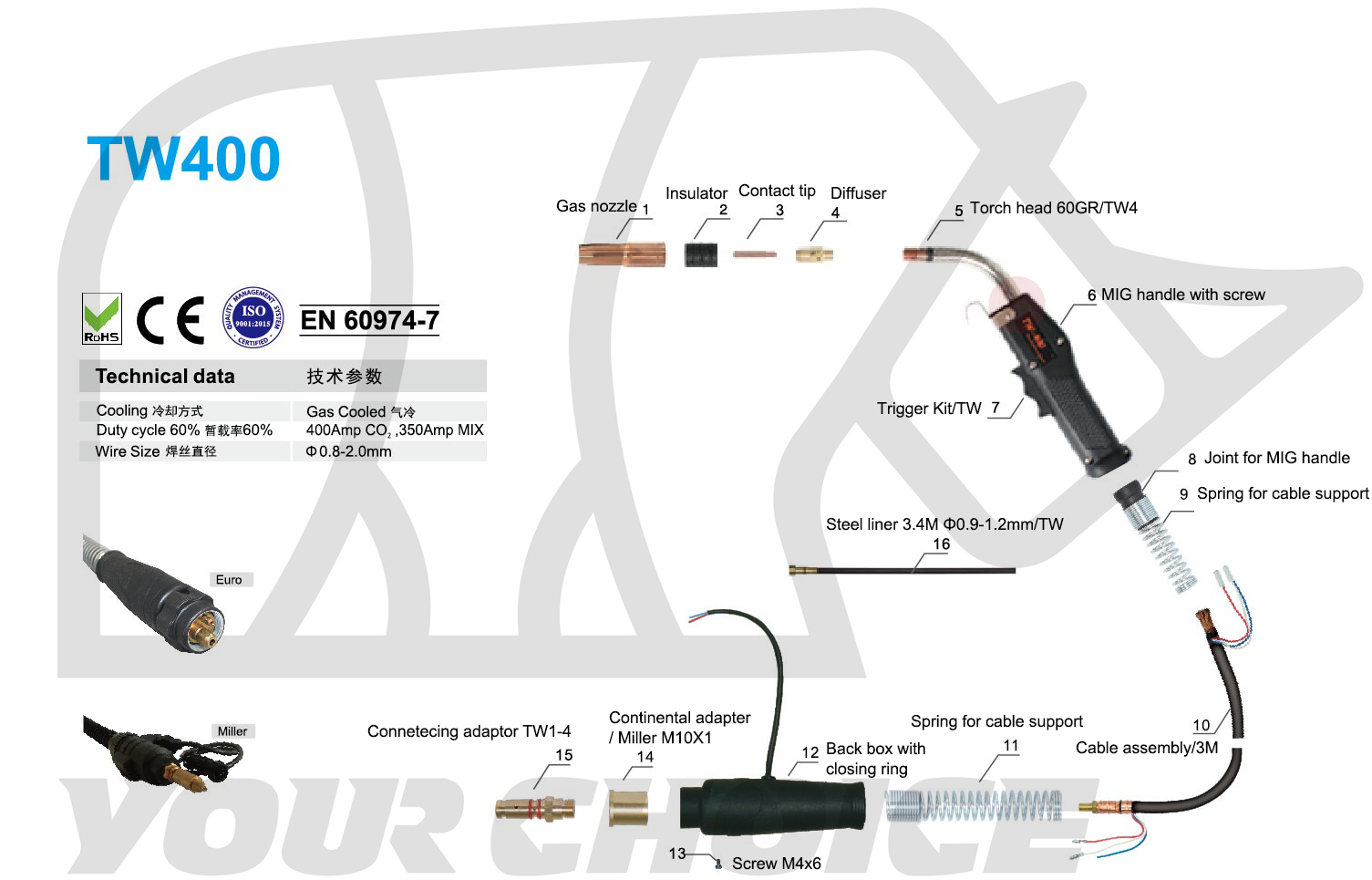

Technical Data:

| Cooling | Gas Cooled | wire size | Φ0.8-2.0mm |

| Duty 60% DC | 400Amp CO2, 350Amp MIX | Package | OPP Bag + 1Set/Box |

| Switches | Single | Length | 3m/4m/6m |

| Certificate | CE & Rohs | Gas nozzle | Φ16 mm |

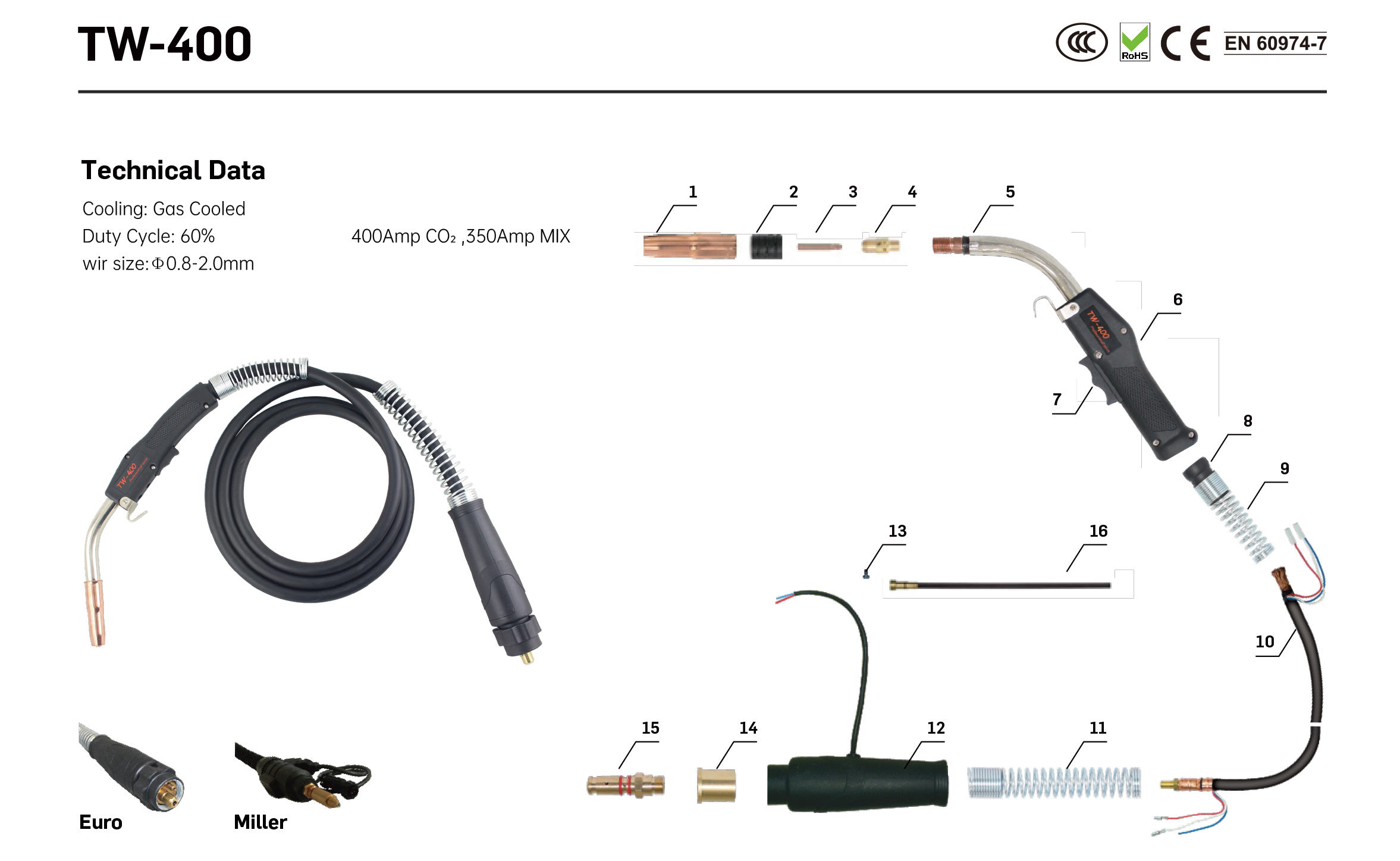

| Position | Code | Ref. | Description |

| 1 | UDT0602 | 24A-62 | Gas nozzle Φ16 |

| 2 | IJDL0697 | 34A | Insulator |

| 3 | IJDV0010-12 | 14-116 | Contact tip Φ1.2mm/ 1/4-28X37.4 |

| 4 | IJDG0081 | 54A | Diffuser |

| 5 | IJDA0600-01 |

| 5 Torch head 60GR/TW4/64J-60/Nickel-plated outer tube |

| 6 | IJDW0704 | 84A | MIG handle with screw |

| 7 | IJIR0092 |

| Trigger Kit/TW |

| 8 | IJIK0788 |

| Joint for MIG handle |

| 9 | IJGU0887-02 |

| Spring for cable support/Zin/Long/TW |

| 10 | IJD00919 |

| Cable assembly/3M |

| 11 | IJGU0835 |

| Spring for cable support/Blue and white zinc plating |

| 12 | IJIK0883 |

| Back box with closing ring |

| 13 | IJGU0074 | EA0018 | Screw M4x6 |

| 14 | IJAI7062 |

| Continental adapter / Miller M10X1 |

| 15 | IJUP0003 |

| Connetecing adaptor TW1-4 |

| 16 | IJJD0010-03 |

| Steel liner 3.4M Φ0.9-1.2mm/TW |

| Complete Torch |

| IJDU5911 | 410-3545 | TW4 Torch 3m |

| IJDU5917 | 412-3545 | TW4 Torch 4m |

| IJDU5918 | 415-3545 | TW4 Torch 4.6m |

| IJDU5926 | X410-3545 | TW4 Torch 3m euro adaptor |

| IJDU5922 | X412-3545 | Tw4 Torch 4m euro adaptor |

| IJDU5923 | X415-3545 | Tw4 Torch 4.6m euro adaptor |

| IJDU5924 | M410-3545 | Tw4 Torch 3m Miller adaptor |

| IJDU5925 | M412-3545 | Tw4 Torch 4m Miller adaptor |

| IJDU5931 | M415-3545 | Tw4 Torch 4.6m Miller adaptor |

Labeled diagram of the components parts of TW400 Gas Cooled Mig Welding Torch & Gun

Introducing our comprehensive diagram of a MIG welding gun, featuring labeled components for easy identification. Our diagram includes all the parts of a MIG gun, including the torch, welder, and gun components, along with detailed descriptions of each. Whether you're looking to repair or upgrade your MIG welding gun, or simply want to learn more about the torch welding process, our diagram is the perfect resource. Explore our guide to find out more about MIG gun parts diagram, labeled parts of a MIG gun, and mig gun components. We also cover mig welding gun parts, parts of a mig welder gun, and mig welder gun parts. Additionally, we provide tips for torch welding aluminum, so you can achieve the best results possible.

Introduction:

The "INWELT WELDING TECH” TW400 Air-Cooled MIG Welding Torch is a classic Tweco Series air-cooled MIG welding torch rated at 400 amps at a 60% duty cycle.

The TW400 MIG welding torch has several advantages over other options on the market. Firstly, its ergonomic design provides improved comfort and control for the welder, reducing fatigue and increasing precision during welding.

Secondly, the TW400 MIG welding torch features a top-loading design that ensures easy and quick replacement of contact tips, reducing downtime and improving productivity.

Thirdly, the TW400 MIG welding torch boasts a tapered contact tip locking system, which ensures a secure fit and eliminates the risk of loose tips that can cause weld defects.

Finally, the TW400 MIG welding torch is designed with high-quality materials and precision manufacturing, ensuring durability and reliability even in harsh welding environments. These advantages make the TW400 MIG welding torch a top choice for welders who value performance, durability, and efficiency.

"INWELT WELDING TECH”also offers a complete stock of consumables and spare parts for the Tweco range of MIG Welding Guns.

About Mig Welding:

⒈ Like TIG welding, it can weld almost all metals, especially suitable for welding aluminum and aluminum alloys, copper and copper alloys, stainless steel and other materials. There is almost no oxidation burning loss during the welding process, only a small amount of evaporation loss, and the metallurgical process is relatively simple.

⒉ high labor productivity

⒊MIG welding can be DC reversed, welding aluminum, magnesium and other metals has a good cathode atomization effect, which can effectively remove the oxide film and improve the welding quality of the joint.

⒋Do not use tungsten electrode, the cost is lower than TIG welding; it is possible to replace TIG welding.

⒌When MIG welding aluminum and aluminum alloys, the sub-jet droplet transfer method can be used to improve the quality of the welded joints.

⒍Since argon is an inert gas and does not chemically react with any substances, it is more sensitive to oil stains and rust on the surface of the welding wire and base metal, and it is easy to generate pores. The welding wire and workpiece must be carefully cleaned before welding.

⒊MIG welding droplet transfer

Droplet transfer refers to the whole process in which the molten metal at the end of the welding wire or electrode forms a droplet under the action of arc heat, and is detached from the end of the welding wire and transferred to the welding pool under the action of various forces. It is directly related to the stability of the welding process, weld formation, spatter size, etc.

⒊1. The force affecting the transfer of molten droplets The droplet formed by the molten metal at the end of the welding wire is affected by various forces, and the influence of various forces on the transfer of the droplet is different. ⒈ Gravity: in the flat welding position, the direction of gravity is the same as the direction of the droplet transfer, which promotes the transition; the overhead welding position hinders the transfer of the droplet

⒉Surface tension: the main force to maintain the droplet on the wire end, the thinner the wire, the easier the droplet transition.

⒊Electromagnetic force: The force generated by the magnetic field of the conductor itself is called electromagnetic force, and its axial component force always expands from a small section to a large section. In molten electrode arc welding, the cross-section of the conductor changes when the current passes through the wire-droplet-electrode spot, and the direction of the electromagnetic force also changes. At the same time, the high current density at the spot will cause the metal to evaporate strongly, and will also have a great reaction force on the surface of the molten metal. The effect of electromagnetic force on droplet transfer depends on the arc shape.

⒋Plasma flow force: Under the contraction of electromagnetic force, the hydrostatic pressure generated by the arc plasma in the direction of the arc axis is inversely proportional to the cross-sectional area of the arc column, that is, it gradually decreases from the end of the welding wire to the surface of the molten pool. Favorable factors to promote droplet transfer.

⒌ Spot pressure

⒊2. Droplet transfer characteristics of MIG welding In MIG welding and MAG welding, short-circuit transfer and jet transfer are mainly used for droplet transfer. Short-circuit welding is used for high-speed welding and all-position welding of thin plates, and jet transfer is used for horizontal butt and fillet welding of medium and thick plates.

In MIG welding, DC reverse connection is basically used. Because the fine jet transition can be achieved in the reverse connection, and the positive ions hit the droplet in the positive connection, which produces a large spot pressure to hinder the droplet transition, so that the normal connection is basically an irregular droplet transition. Alternating current is not suitable for MIG welding because the melting of the wire is not equal on each half-circle.

When using MIG welding to weld aluminum and aluminum alloys, because aluminum is easy to oxidize, in order to ensure the protection effect, the arc length cannot be too long during welding, so we cannot use the jet transition method with large current and long arc length. If the selected current is greater than the critical current, and the arc length is controlled between the jet transition and the short-circuit transition, a sub-jet transition is formed.

MIG welding is now widely used for welding aluminum and aluminum alloy workpieces.

Application Areas:

» General engineering

» Construction industries

» Power cycle

» Railway industries

» Heavy duty industry

Our Catalog:

INWELT MIG WELDING TORCH.pdf

INWELT MIG WELDING TORCH.pdf

FAQ:

Q1: Can I have a sample for testing?

A: Yes, we can support sample. The sample will be charged reasonably according to the negotiation between us.

Q2: Can I add my logo on the boxes/cartons?

A: Yes, we have a R&D capability and professional & efficient team, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: Special discount Marketing protection.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftermarket support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 Feet High Cube Containers, but 20 feet containers are also acceptable.

Q6: Can I have a visit to your factory before the order?

A: Sure, welcome your visit to our factory.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių