LT100 Plasma Cutting Torch for 100A Plasma Cutter Machine

Overview of the LT100 Plasma Cutting Torch

The LT100 Plasma Cutting Torch is a high-performance tool designed for precision cutting in industrial applications. Compatible with 100A plasma cutting CNC machines, this torch features high-frequency (HF) ignition for easy arc starting and a robust design for durability. Manufactured by Inwelt, the LT100 is ideal for professionals seeking reliable plasma cutting solutions.

Key Features of the LT100 Plasma Cutting Torch

High-Frequency Ignition: Ensures reliable and efficient arc starting for precise cutting.

Cutting Capacity: Capable of cutting materials up to 40mm thick with accuracy.

High-Quality Materials: Constructed with tellurium copper, hafnium, and Vespel for enhanced durability.

CNC Compatibility: Designed to work seamlessly with standard 100A plasma cutting machines.

Air Cooling System: Prevents overheating, maintaining optimal performance during operation.

Compatibility with 100A CNC Plasma Machines

The LT100 is engineered for smooth integration with 100A CNC plasma cutting machines, including popular brands. It ensures precise, repeatable cuts, making it suitable for industries like automotive, metal fabrication, and construction.

Why Choose the LT100 Plasma Cutting Torch?

The LT100 stands out due to its high-quality materials, including tellurium copper, hafnium, and Vespel, ensuring long-lasting performance. Its compatibility with 100A CNC plasma machines and ease of use make it a top choice for professionals in metal fabrication, automotive repair, and industrial manufacturing.

Benefits for Industrial Applications

Enhanced precision for complex cuts on various metals.

Reliable performance with high-frequency ignition for consistent arc starts.

Designed for integration with automated CNC systems or robotic arms.

How to Use the LT100 Plasma Cutting Torch

Operating the LT100 is straightforward, thanks to its HF ignition and ergonomic design. Follow these steps for optimal performance:

Connect the torch to a compatible 100A plasma cutting machine.

Ensure proper air supply for cooling and cutting efficiency.

Adjust settings based on material thickness (up to 40mm).

Initiate the arc using the high-frequency ignition system.

Perform cuts with steady, controlled movements for best results.

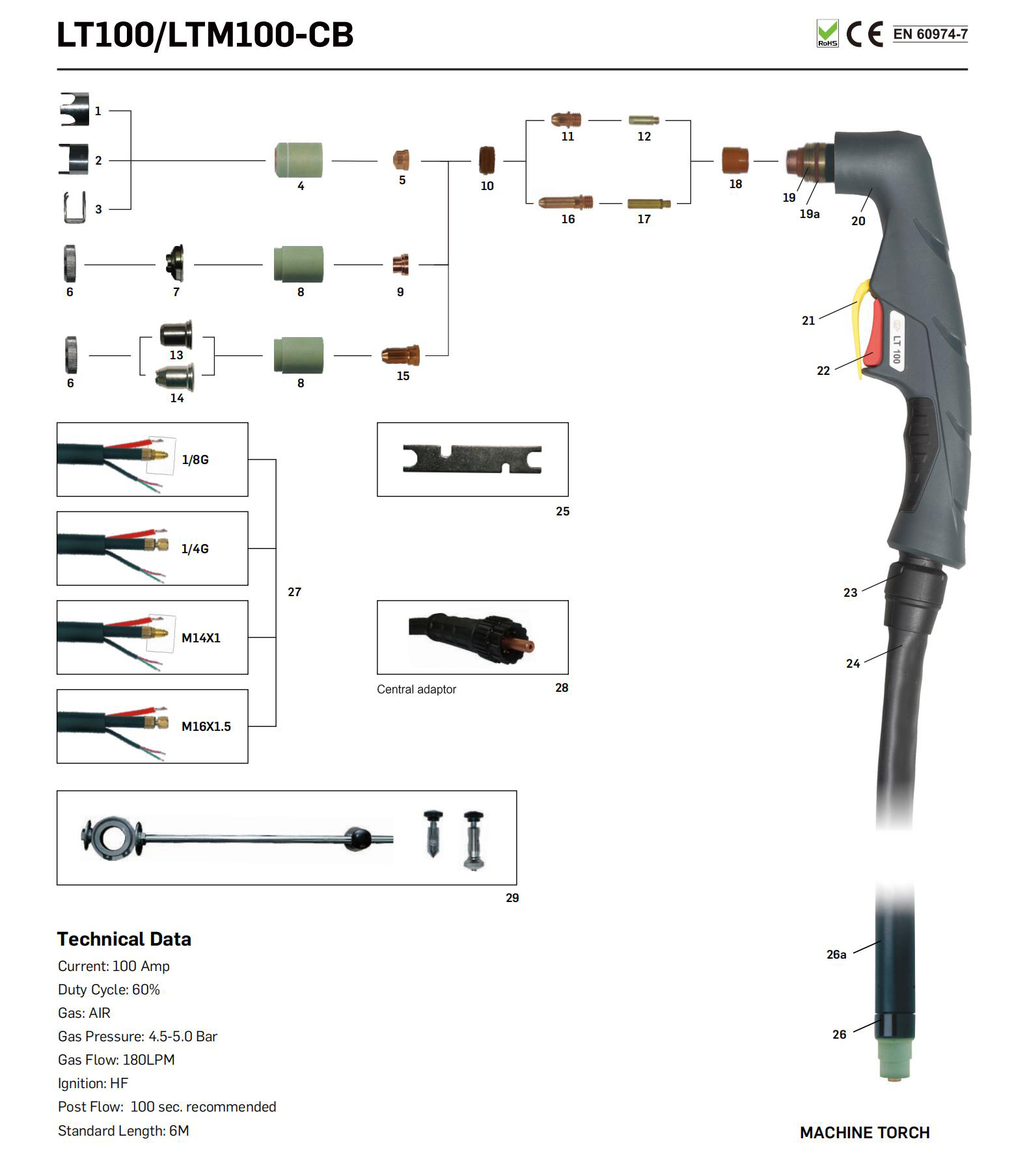

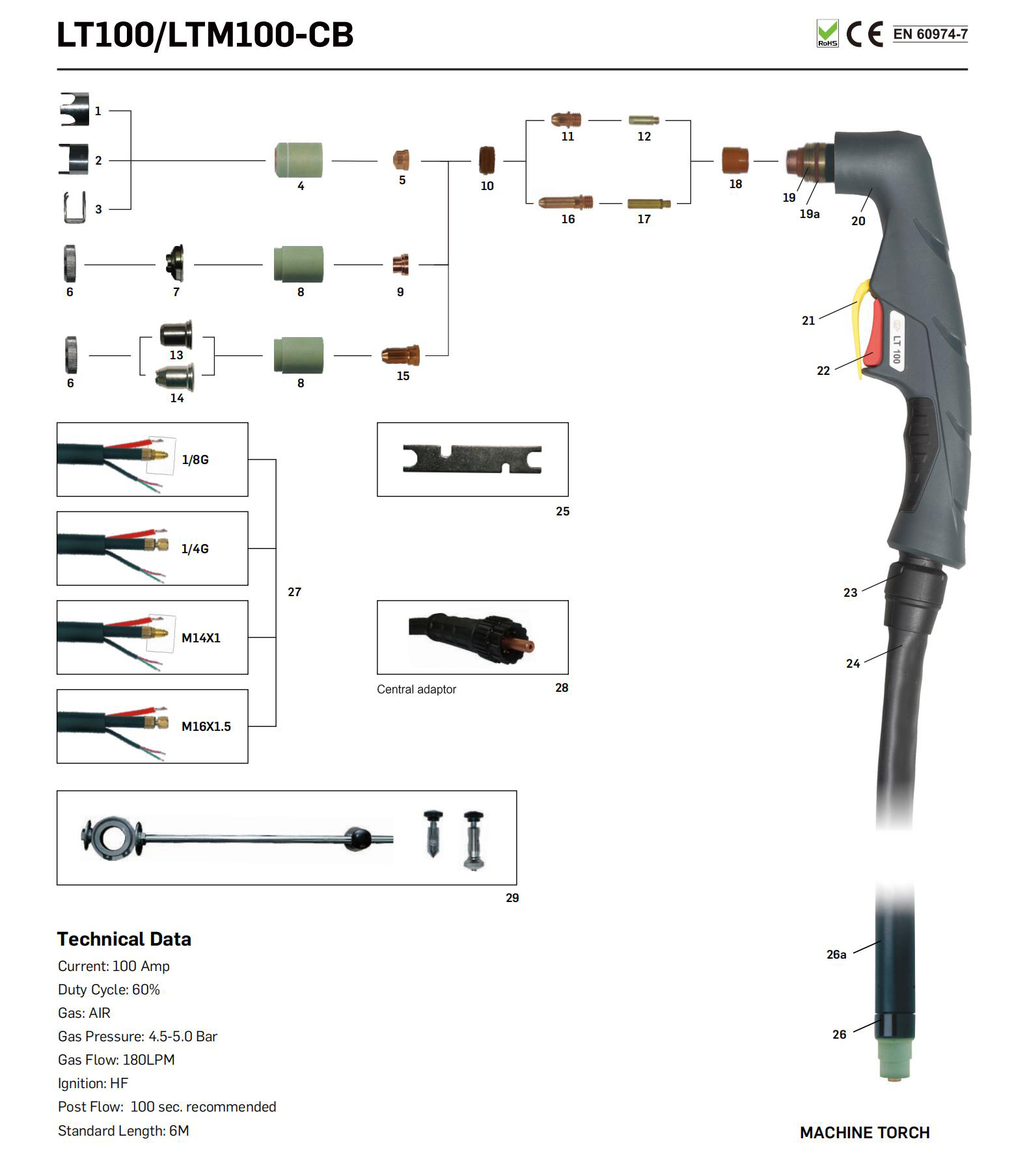

Technical Data:

| Current | 100Amp | Gas Flow | 180LPM |

| Duty Cycle | 60% | Ignition | HF |

| Gas | Air | Post Flow | 100 seconds recommended |

| Gas Pressure | 4.5-5.0 Bar | Standard Length | 6M |

LT100 Plasma Cutting Torch Application Scenarios

Metal Fabrication: Perfect for cutting precise shapes in steel, stainless steel, and aluminum up to 40mm thick, ideal for custom metal parts and structures.

Automotive Repair: Used in auto shops for cutting metal panels, chassis, and exhaust components with high precision and efficiency.

Industrial Manufacturing: Supports high-volume production with its robust design, suitable for manufacturing heavy machinery and industrial equipment components.

CNC Machining: Integrates seamlessly with 100A CNC plasma cutting machines for automated, repeatable cuts in large-scale production settings.

Construction: Employed for cutting structural steel, beams, and pipes on construction sites, offering reliable performance for heavy-duty tasks.

Shipbuilding: Facilitates precise cutting of thick metal plates for ship components, leveraging HF ignition and air cooling for consistent results.

Metal Art and Sculpture: Enables artists to create intricate designs and sculptures in various metals with clean, accurate cuts.

Spare Parts Details:

| HAND TORCH |

| Code | Ref. | Description |

| IJWU6961 | PA1450 | Plasma cutting torch LT100/6m 1/8G |

| IJWU6967 |

| Plasma cutting torch LT100/6m 1/4G |

| IJWU6968 | PA1452 | Plasma cutting torch LT100/6m M14×1 |

| IJWU6969 |

| Plasma cutting torch LT100/6m M16×1.5 |

| IJWU6960 |

| Plasma cutting torch LT100/6m central adaptor |

| Machine | Torch |

|

| Code | Ref. | Description |

| IJWU0671 | PA0110 | Plasma cutting auto torch LTM100/6m 1/8G |

| IJWU0677 | PA0111 | Plasma cutting auto torch LTM100/6m M14×1 |

| IJWU0692 |

| Plasma cutting auto torch LTM100/6m M16×1.5 |

| IJWU0693 |

| Plasma cutting auto torch LTM100/6m central adaptor |

| IJWU0694 |

| Plasma cutting auto torch LTM100/6m 1/4G |

|

| Positio | Code | Ref. | Description |

| 1 | IJTN0069 | CV0014 | Four point edspacer/LT100-150 |

| 2 | IJTN0078 | CV0012 | Double point edspacer/LT100-150 |

| 3 | IJTN0077 | CV0011 | Spacer spring LT100-150 |

| 4 | IJWT0677 | PC0111 | Outside nozzle LT101 |

| 5 | IJTN0095 | CV0039 | Four point crown shield with insulator/LT101-141 |

| 6 | IJTN0089 | CV0023 | Spacer for contact cutting/LT101-141 |

| 7 | IJWT0691 | PC0130 | Contact nozzle retaining cap/LT101 |

| 8 |

|

| Tip |

| 8.1 | IJWV0617-11 | PD0101-11 | Tip Φ1.1mm LT101-141 |

| 8.2 | IJWV0617-14 | PD0101-14 | Tip Φ1.4mm LT101-141 |

| 8.3 | IJWV0617-17 | PD0101-17 | Tip Φ1.7mm LT101-141 |

| 9 | IJWG0617 | PE0101 | Diffuser LT101-141 |

| 10 | IJWC0617 | PR0101 | Electrode Plasma LT101-141 |

| 11 | IJAO0770 |

| Airtube/LT100-101 |

| 12 | IJTN0000 |

| Locking nut |

| 13 | IJTN0014 | CV0008 | Contact cutting attachment/LT101-151 |

| 14 | IJTN0015 | CV0009 | Long contact cutting attachment/LT101-151 |

| 15 |

|

| Tip |

| 15.1 | IJWV0673-14 | PD0117-14 | Extended tip Φ1.4mm/LT101-151 |

| 15.2 | IJWV0673-17 | PD0117-17 | Extended tip Φ1.7mm/LT101-151 |

| 15.3 | IJWV0677 |

| Extended tip 50A/LT101-151 |

| 16 | IJWC0672 | PR0116 | Extended electrode Plasma LT101 |

| 17 | IJWA0606 |

| Plasma torch head LT101 |

| 17a | IJGU0697 | EA0131 | “O”ring Φ18.77x1.78mm in silicon |

| 17b | IJWG9017 |

| Frontin sulator/LT101 |

| 18 | IJHW0046 |

| Plasma hand lemanual/ASeries/Red |

| 19 | IJIK0733 |

| Protection part/Plasma/Yellow |

| 20 | IJIR0081 | 185.0031 | Trigger |

| 21 | IJIK0805 |

| Joint/big/new type |

| 22 |

|

| Cable assembly |

| 22.1 | IJWO00210077-00 |

| Cable assembly/LT100-101/10MMQ/6MATT.1/8G |

| 22.2 | IJWO00210071-00 |

| Cable assembly/LT100-101/10MMQ/6M central adaptor |

| 22.3 | IJWO10210077-00 |

| Cable assembly/LTM100-101/10MMQ/6MATT.1/8G |

| 22.4 | IJWO10210071-00 |

| Cable assembly/LTM100-101/10MMQ/6M central adaptor |

| 22.5 | IJWO0642 |

| Cable assembly/LT100-101/6M/central adaptor |

| 23 | IJDH6017 |

| Spanner for Plasma |

| 24 | IJWA0676 |

| Plasma torch head LTM101 |

| 24a | IJHW0024 | W0300144 | Fiber glass position tube/LTM |

| 25 |

|

| Cable assembly LTM |

| 25.1 | IJAU5698 |

| Connecting adaptor 1/8G-1/4G |

| 25.2 | IJAU5697 |

| Connecting adaptor 1/8G-3/8G |

| 25.3 | IJAU5699 |

| Connecting adaptor 1/8G-M14×1 |

| 25.4 | IJAU5690 |

| Connecting adaptor 1/8G-M16×1.5 |

| 26 IJAY0089 FY0023 Central adaptor torch side Plasma 5pins |

| 27 IJTN0088 CV0022 Circle cutting attachment/LT100-151 |

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

LT100 Plasma Cutting Torch FAQs

1. What materials can the LT100 Plasma Cutting Torch cut?

The LT100 can cut conductive metals such as steel, stainless steel, aluminum, and copper, with a maximum cutting capacity of up to 40mm, depending on the material and plasma cutter settings.

2. Is the LT100 compatible with all 100A plasma cutters?

The LT100 is compatible with standard 100A plasma cutting CNC machines. It’s designed to work with popular brands, but always confirm compatibility with your specific machine model before purchasing.

3. What is the cutting capacity of the LT100 Plasma Cutting Torch?

The LT100 can cut materials up to 40mm thick, making it suitable for heavy-duty industrial applications requiring precise and clean cuts.

4. How does the high-frequency (HF) ignition work?

HF ignition uses a high-voltage, low-current spark to initiate the plasma arc, ensuring easy and reliable arc starting, particularly for CNC and automated cutting tasks.

5. What materials are used in the LT100 Plasma Cutting Torch?

The LT100 is constructed with high-quality materials, including tellurium copper, hafnium, and Vespel, which enhance durability and performance under demanding conditions.

6. What cooling system does the LT100 use?

The LT100 features an air-cooling system that prevents overheating, ensuring consistent performance and extending the torch’s lifespan during prolonged use.

7. Can the LT100 be used with robotic arms or automated systems?

Yes, the LT100 is designed for integration with CNC plasma cutting machines and robotic arms, making it ideal for automated, high-precision cutting applications.

8. How do I maintain the LT100 Plasma Cutting Torch?

Regularly inspect and replace consumables (e.g., electrodes, nozzles), ensure proper air supply for cooling, and clean the torch to maintain optimal performance. Refer to the user manual for specific maintenance guidelines.

9. Where can I purchase the LT100 Plasma Cutting Torch?

The LT100 can be purchased from INWELT’s official website or authorized distributors. For more details or to place an order, contact Inwelt directly or visit their product page.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių