Key Features and Technological Advantages of the LT70

The INWELT LT70/LTM70-CB Plasma Cutting Torch incorporates several innovative features and relies on high-quality materials to ensure its exceptional performance and durability.

High-Frequency (HF) Ignition for Reliable Arc Starting

One of the standout features of the LT70 is its High-Frequency (HF) Ignition system. This advanced starting mechanism ensures immediate and consistent arc initiation without requiring direct contact with the workpiece. The benefits are manifold: reduced wear and tear on consumables, extended consumable life, and a cleaner, more precise start to every cut. For busy workshops, HF ignition translates directly to increased uptime and reduced operational costs.

Exceptional Material Composition for Longevity and Performance

The durability and efficiency of the LT70/LTM70-CB are largely attributed to the premium materials used in its construction. Key components are crafted from:

High-Quality Tellurium Copper: Used for tips and electrodes, this material offers excellent electrical conductivity and heat resistance, crucial for maintaining arc stability and extending consumable life.

US Hafnium: Integrated into electrodes, Hafnium is known for its superior electron emission properties, which significantly enhance arc stability and electrode lifespan under intense heat.

Vespel Material: Employed in critical insulating components, Vespel provides exceptional thermal stability and mechanical strength, ensuring the torch operates reliably even at high temperatures.

This meticulous selection of materials ensures the torch can withstand the rigors of plasma cutting, offering a long service life and consistent performance.

Robust Cutting Capacity: Powering Through 30mm Thick Materials

Optimized for 70A current, the LT70 Plasma Cutting Torch boasts an impressive cutting capacity, capable of cleanly severing plates up to 30mm thick. This makes it an incredibly versatile tool for a wide array of metalworking projects, from medium-gauge fabrication to significant material processing. The torch maintains a stable and concentrated plasma arc, crucial for achieving precise cuts with minimal dross and distortion.

Enhanced User Comfort and Durability

Understanding the importance of operator comfort during prolonged use, the INWELT LT70 features a high-density plastic handle. This ergonomic design provides a secure and comfortable grip, reducing operator fatigue and allowing for greater control and precision. Furthermore, an insulated cable cover protects the torch's internal wiring from abrasive environments, high temperatures, and accidental damage, significantly extending the cable's lifespan and ensuring reliable current delivery. This dual focus on comfort and durability makes the LT70 a preferred choice for professionals.

Comprehensive Consumables Package

The LT70/LTM70-CB comes ready for action with a pre-installed set of essential consumables. This includes:

Nozzle (Tip): Crucial for constricting the plasma arc and directing the gas flow.

Electrode: Generates the plasma arc.

Swirl Ring (Diffuser): Shapes the gas flow to create a stable plasma stream.

Shield Cup: Protects the internal components from molten metal splatter and provides the correct standoff distance. Having these consumables pre-installed means you can begin your cutting tasks immediately upon receiving your torch.

Efficient Air Cooling System

The LT70/LTM70-CB is air-cooled, a practical and efficient cooling method for its amperage range. This system uses the flow of the plasma gas (air) to cool the torch components, ensuring consistent performance and preventing overheating during operation. Air cooling also eliminates the need for a separate water cooling unit, making the system simpler, lighter, and more portable.

Why Choose Changzhou Inwelt for Your Plasma Cutting Solutions?

Selecting the right manufacturing partner for your cutting equipment is crucial for long-term success. Changzhou Inwelt is a leading provider, distinguished by its unwavering commitment to quality, innovation, and customer satisfaction.

Uncompromising Commitment to Quality and Reliability

At Changzhou Inwelt, every LT70 Plasma Cutting Torch undergoes stringent quality control at every stage of production. From the selection of premium materials like tellurium copper, US hafnium, and Vespel to the final assembly and testing, our engineers ensure that each torch meets rigorous industry standards. This dedication guarantees that you receive a reliable, high-performance product built for endurance.

Global Compatibility and Seamless Integration

Our torches are designed with global usability in mind. The LT70/LTM70-CB's high-frequency ignition and compatibility with standard 70A plasma cutting machines from various brands ensure easy integration into diverse workshop environments worldwide. We provide solutions that fit your existing setup.

Comprehensive Customer Support and Partnership Programs

We believe in building lasting relationships with our clients and distributors, offering extensive support and flexible partnership programs:

Sample Availability: We offer product samples (with a reasonable charge) allowing potential customers to evaluate the LT70's quality and performance firsthand before committing to larger orders.

OEM/ODM Services: For businesses requiring customized solutions or private labeling, Changzhou Inwelt provides comprehensive OEM/ODM services, tailoring products to meet specific branding, technical, or market requirements.

Distributor Benefits: We value our distribution partners and offer exclusive benefits, including special discounts and marketing protection, to support their growth and success in their respective markets.

Flexible Shipping Solutions: Understanding diverse logistical needs, we accommodate mixing various items in 40 Feet High Cube and 20 Feet containers, offering efficiency and convenience for your inventory and shipping arrangements.

Factory Visits Welcome: We extend an open invitation to potential clients to visit our manufacturing facilities. Witness our state-of-the-art production processes, stringent quality assurance protocols, and meet our dedicated team to gain full confidence in our capabilities and commitment to excellence.

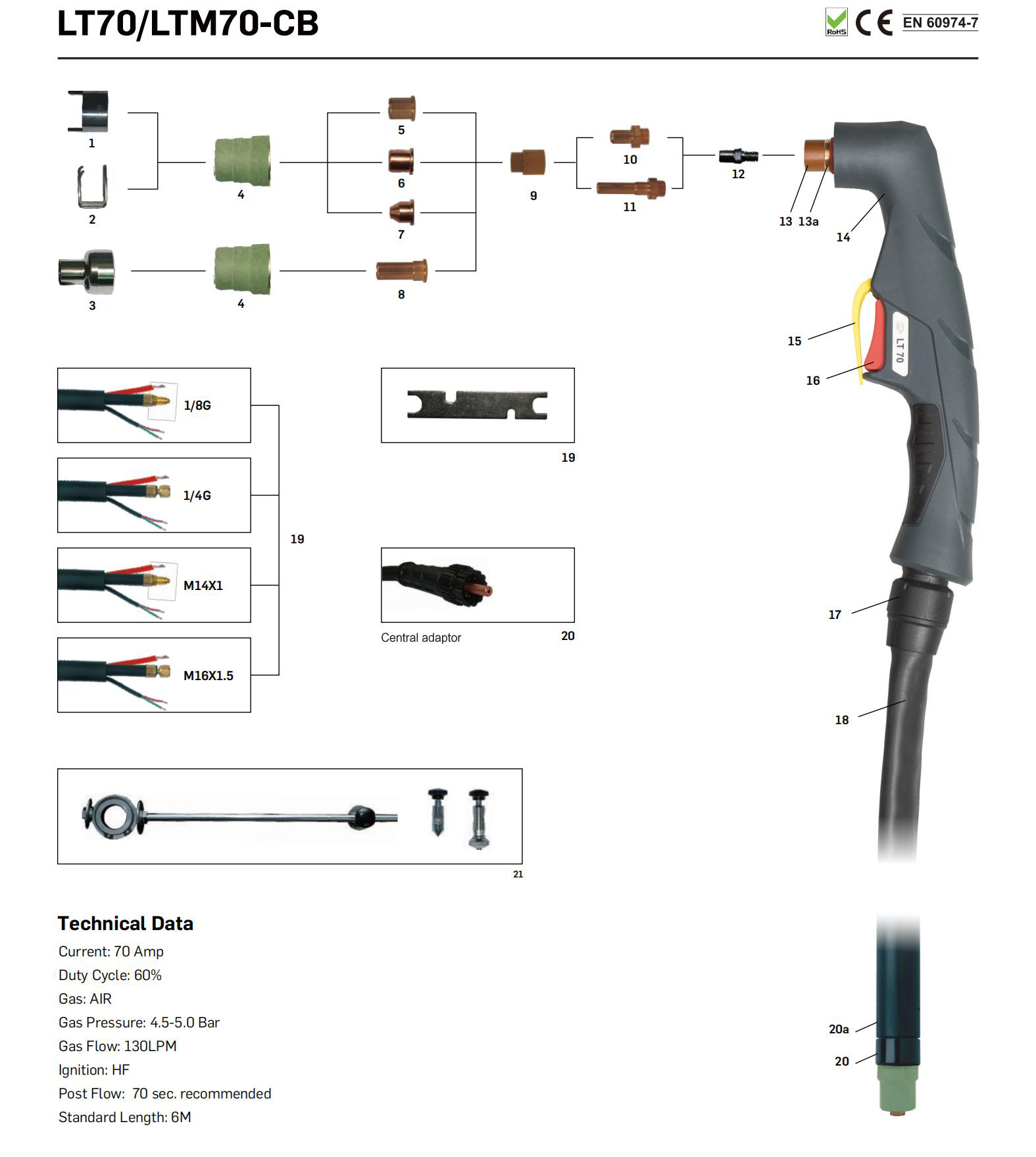

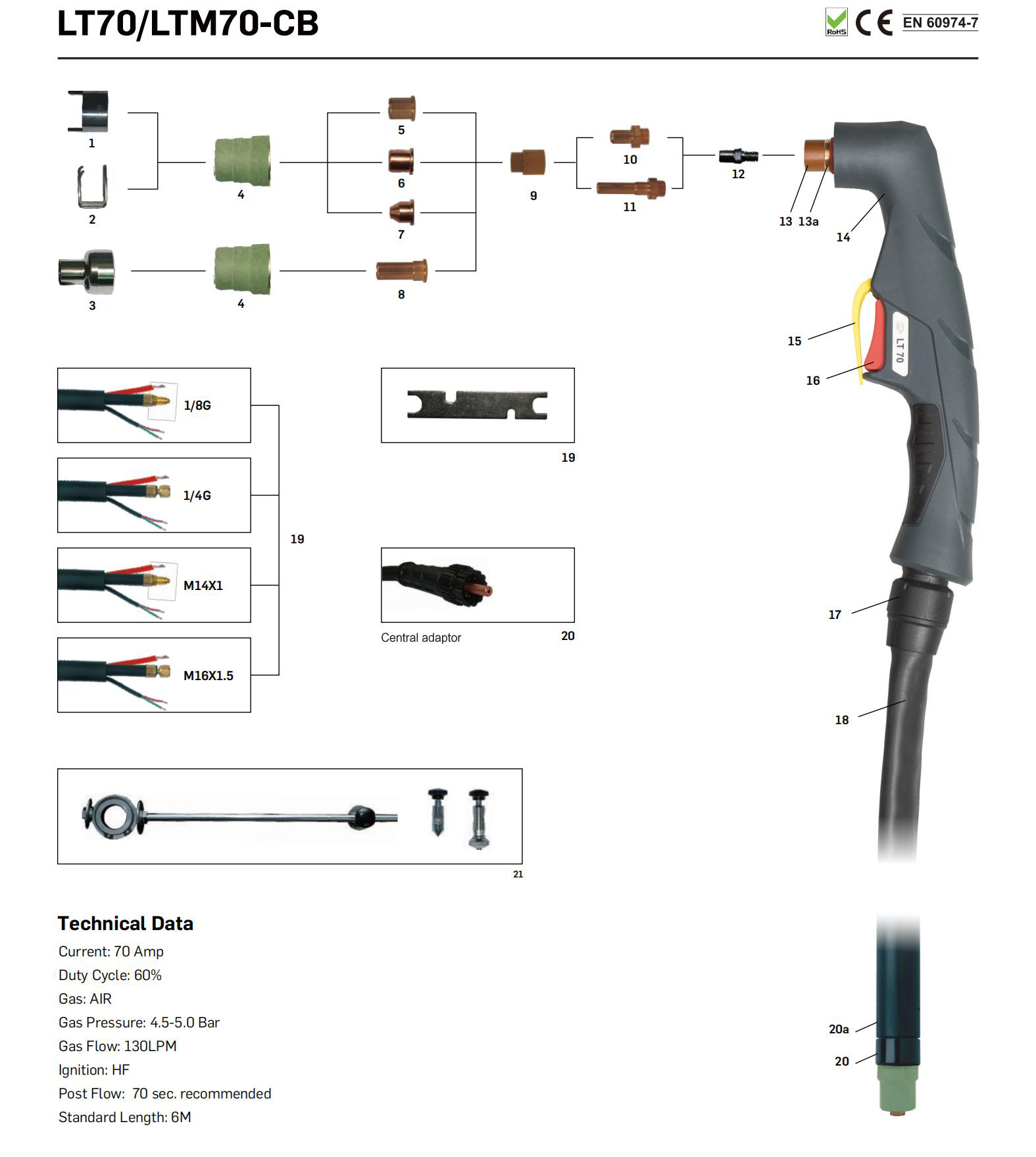

Technical Data:

| Current | 70Amp | Gas Flow | 130LPM |

| Duty Cycle | 60% | Ignition | HF |

| Gas | Air | Post Flow | 70 seconds recommended |

| Gas Pressure | 4.5 - 5.0 Bar | Standard Length | 6M |

Detailed Technical Specifications: Performance at a Glance

Understanding the technical specifications of the INWELT LT70/LTM70-CB provides a clear picture of its operational capabilities and suitability for your specific cutting needs.

Recommended Post-Flow: 70 seconds - This vital post-flow period allows the compressed air to continue flowing after the arc is extinguished, effectively cooling the torch's nozzle and electrode. This helps prevent premature wear and extends consumable lifespan by mitigating thermal shock.

Gas Pressure: 4.5-5.0 Bar - Maintaining this recommended gas pressure is crucial for optimal plasma arc formation, consistent cut quality, and efficient consumable usage.

Standard Length: 6 meters (approximately 20 feet) - Provides ample reach and flexibility for navigating around larger workpieces and versatile positioning within your workspace.

The Significance of a 60% Duty Cycle

A 60% duty cycle at 70 Amps is a strong indicator of the LT70/LTM70-CB's robust construction and efficient thermal management. For professional applications where continuous operation is often required, a higher duty cycle translates directly to increased productivity and reduced interruptions for equipment cooling. This means more cutting time and less waiting.

Optimizing Gas Flow and Pressure for Superior Cuts

The precise gas flow rate of 130 LPM and the recommended pressure range of 4.5-5.0 Bar are critical for maximizing the performance of the LT70. These settings ensure the plasma arc is tightly constricted and powerful enough to cut efficiently. It is crucial to use a clean, dry, oil-free air supply, as contaminants can negatively impact arc stability, cut quality, and significantly reduce the life of your consumables. Investing in good air filtration and drying systems will pay dividends in torch performance and consumable savings.

Diverse Applications Across Industries

The versatility and reliable performance of the INWELT LT70 Plasma Cutting Torch make it an invaluable asset across a wide array of industrial and commercial sectors.

General Engineering and Fabrication

For general engineering workshops and fabrication businesses, the LT70 is an indispensable tool. Its ability to deliver clean, precise cuts on various metals up to 30mm thick makes it perfect for fabricating custom components, repair work, light structural elements, and artistic metalwork. Its ease of use and consistent performance streamline production processes.

Construction Industries

In construction, efficient material processing is key. The LT70's cutting capacity and robust design make it highly suitable for on-site fabrication and modification of structural steel, rebar, sheet metal, and other components required in building and infrastructure projects. Its durability ensures it can withstand the often-harsh conditions of a construction environment.

Power Cycle (Energy Sector) Applications

The energy sector, encompassing power generation plants and renewable energy installations, often requires precise cutting for maintenance, repair, and modification of metal structures and piping. The LT70's reliable performance at 70A makes it an excellent choice for these critical applications, contributing to efficient and safe operations.

Railway Industries

The railway industry involves extensive metalwork, from maintaining existing tracks and rolling stock to fabricating new components. The LT70's power and precision are well-suited for handling the medium-gauge metals typically found in railway applications, supporting efficient infrastructure development and maintenance.

Heavy-Duty Industrial Use

While rated at 70A, the LT70's robust construction and consistent performance make it a valuable tool in aspects of heavy-duty industries such as heavy machinery manufacturing, shipbuilding, and mining. It efficiently handles specific cutting tasks within these sectors where mid-range thickness cutting is common, offering a balance of power and precision.

Consumables and Maintenance: Ensuring Torch Longevity

To maximize the performance, efficiency, and lifespan of your INWELT LT70 Plasma Cutting Torch, proper maintenance and the timely replacement of genuine consumables are absolutely essential.

Critical Consumables for Peak Performance

The INWELT LT70/LTM70-CB comes equipped with a basic set of consumables to get you started immediately. These vital components include:

Nozzles (Tips): Different orifice sizes are available for various cutting requirements and amperages. They focus the plasma arc.

Electrodes: The component from which the plasma arc originates. It wears down with use and needs regular replacement.

Swirl Rings (Gas Diffusers): Control the flow of plasma gas to create a stable, focused arc.

Shield Cups: Protect the internal components from molten metal splatter and maintain the correct standoff distance from the workpiece.

Changzhou Inwelt provides a detailed list of various spare parts for both hand (LT70) and machine (LTM70-CB) torches, including different types of tips, electrodes, and cable assemblies. Always insist on using genuine INWELT consumables. Using inferior or non-OEM consumables can lead to poor cut quality, excessive wear on the torch, and even damage to your plasma power supply.

Best Practices for Torch Maintenance

Implementing a consistent maintenance routine will significantly extend the life of your LT70 torch and ensure optimal cutting performance:

Regular Consumable Inspection: Before each cutting session, visually inspect the nozzle, electrode, swirl ring, and shield cup. Look for signs of wear, pitting, dross buildup, or an enlarged orifice. Replace them proactively, even if they appear minimally worn, to maintain cut quality.

Maintain Clean Air Supply: Contaminated compressed air (containing moisture, oil, or particulates) is the biggest enemy of plasma consumables. Invest in high-quality air filters and dryers for your air compressor system to ensure a clean, dry air supply.

Verify Gas Pressure and Flow: Always set the gas pressure and flow rate according to the recommended specifications (4.5-5.0 Bar and 130 LPM). Incorrect settings can lead to an unstable arc, poor cuts, and rapid consumable wear.

Clean Torch Body: Regularly clean the torch body, especially around the consumable housing, to remove any accumulated spatter or debris.

Handle with Care: While the LT70 is robust, avoid dropping or applying excessive force to the torch. The insulated cable cover offers protection, but continuous abuse can lead to internal damage.

Spare Parts Details:

Hand Torch

|

| Code | Ref. | Description |

| IJWU6881 | 1564 | Plasma cutting torch LT70/6m 1/8G |

| IJWU6887 |

| Plasma cutting torch LT70/6m 1/4G |

| IJWU6886 |

| Plasma cutting torch LT70/6m M16×1.5 |

| IJWU6888 | 1573 | Plasma cutting torch LT70/6m central adaptor |

Machine Torch

|

| Code | Ref. | Description |

| IJWU6751 | 1563 | Plasma cutting auto torch LTM70/6m 1/8G |

| IJWU6753 |

| Plasma cutting auto torch LTM70/6m 1/4G |

| IJWU6755 |

| Plasma cutting auto torch LTM70/6m M16×1.5 |

| IJWU6757 | 1566 | Plasma cutting auto torch LTM70/6m central adaptor |

|

| Positio |

| Code | Ref. | Description |

| 1 |

| IJTN6673 | 1405 | Double pointed spacer/LT70 |

| 2 |

| IJTN0071 | 1394 | Spacer spring/LT70 |

| 3 |

| IJTN0018 |

| Shield cap for Extended tip/LT70 |

| 4 |

|

|

| Outside nozzle |

| 4.1 |

| IJWT0098- 03 | 5.710.171 | Outside nozzle /bakelite/LT70 |

| 4.2 |

| JWT0098-01 |

| Outside nozzle/maximum life/gray glass fiber/LT70 |

| 5 |

|

|

| Tip |

| 5.1 |

| IJWV0076-09 | 1309 | Tip Φ0.9mm LT50-70/L=11.2mm |

| 5.2 |

| IJWV0044-10 | 1396 | Tip Φ1.0mm LT50-70/L=12.3mm |

| 5.3 |

| IJWV0044-11 |

| Tip Φ1.1mm LT50-70/L=12.3mm |

| 5.4 |

| IJWV0044-12 |

| Tip Φ1.2mm LT50-70/L=12.3mm |

| 6 |

|

|

| Tip |

| 6.1 |

| IJWV0039-10 |

| Flat tip Φ1.0mm |

| 6.2 |

| IJWV0039-12 |

| Flat tip Φ1.2mm |

| 7 |

|

|

| Tip |

| 7.1 |

| IJWV0075-10 | 1305 | Conical tip Φ1.0mm/LT50-70 |

| 7.2 |

| IJWV0075-12 |

| Conical tip Φ1.2mm/LT50-70 |

| 8 |

|

|

| Tip |

| 8.1 |

| IJWV0046-98 | 1395 | Extended tip Φ1.0mm/LT50-70 |

| 8.2 |

| IJWV0029-10 |

| Extended tip Φ1.1mm/LT50-70 |

| 8.3 |

| IJWV0029-11 |

| Extended tip Φ1.2mm/LT50-70 |

| 9 |

| IJWG0013 |

| Diffuser LT50-70 |

| 10 |

| IJWC0029 | 1402 | Electrode HF Plasma LT70 |

| 11 |

| IJWC0020 | 1368 | Extended electrode HF Plasma LT70 |

| 12 |

| IJAO0777 | 3.065.204 | Airtube/LT70 |

| 13 |

| IJWA0026 | 1071 | Plasma torch head LT70 |

| 13a |

| IJGU0718 |

| "O"ring Φ12.42x1.78mm in silicon red |

| 14 |

| IJHW0040 |

| Plasma handle manual/CB50-70/Red |

| 15 |

| IJIK0733 |

| Protection part/Plasma/Yellow |

| 16 |

| IJIR0081 | 185.0031 | Trigger |

| 17 |

| IJIK0804 |

| Joint/small/new type |

| 18 |

|

|

| Cable assembly |

| 18.1 |

| IJWO00006077-00 |

| Cable assembly/LT50-70/6MMQ/6M ATT.1/8G |

| 18.2 |

| IJWO00006071-00 |

| Cable assembly/LT50-70/6MMQ/6M center adaptor |

| 18.3 |

| IJWO10006071-00 |

| Cable assembly/LTM50-70/6MMQ/6M central adaptor |

| 18.4 |

| IJWO10006077-00 |

| Cable assembly/LTM50-70/6MMQ/6M ATT.1/8G |

| 19 |

| IJDH6017 |

| Spanner for Plasma |

| 20 |

| IJWA0084 | 1349 | Plasma torch head LTM70 |

| 20a |

| IJHW0024 |

| Fiber glass position tube/LTM |

| 21 Adaptor |

| 21.1 IJAU5698 Connecting adaptor 1/8G-1/4G |

| 21.2 IJAU5699 Connecting adaptor 1/8G-M16×1.5 |

| 21.3 IJAU5690 Central adaptor torch side Plasma 5 pins |

| 22 IJAY0089 Circle cutting attachment/LT70 |

| 22.1 IJTN0030 Wheel spacer with spanner/LT70 |

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

FAQ:

1. What plasma cutter machines is the LT70/LTM70-CB torch compatible with?

The LT70/LTM70-CB torch is designed for standard 70A Plasma Cutter Machines. It's compatible with major brands like Rilon, Riland, Jasic, Mitech, Chiry, UNT, Krypton, and Longetivity.

2. What is the maximum cutting thickness of the LT70 torch?

The LT70 Plasma Cutting Torch can efficiently cut plates up to 30mm (approximately 1.18 inches) thick when used with a 70A plasma cutter machine.

3. Does the LT70 torch use High-Frequency (HF) ignition?

Yes, the LT70/LTM70-CB features High-Frequency (HF) Ignition for reliable and non-contact arc starting, which helps minimize consumable wear.

4. What is the duty cycle of the LT70 torch?

The LT70 has a 60% duty cycle, meaning it can operate at its full 70 Amp output for 6 minutes out of every 10-minute period. This ensures sustained performance for demanding tasks.

5. What consumables are typically included with the LT70 torch?

The LT70/LTM70-CB comes with a set of pre-installed essential consumables, including a nozzle (tip), electrode, swirl ring (diffuser), and shield cup, allowing you to start cutting immediately.

6. What type of gas does the LT70 torch use, and what are the recommended settings?

The LT70 uses air as its plasma gas. The recommended gas flow is 130 LPM, and the optimal gas pressure is between 4.5-5.0 Bar. Always ensure a clean and dry air supply.

7. How does the choice of material (Tellurium Copper, US Hafnium, Vespel) benefit the torch?

These high-quality materials are chosen for their excellent electrical conductivity, heat resistance, and mechanical strength. They contribute to superior arc stability, extended consumable lifespan, and overall torch durability, ensuring consistent high-performance cutting.

8. Is the LT70 available as a machine torch for CNC applications?

Yes, the LTM70-CB variant is specifically designed as a machine torch, making it suitable for integration into CNC plasma cutting tables for automated and precise cutting operations.

9. Can I request a sample of the LT70 torch for testing?

Yes, Changzhou Inwelt offers product samples of the LT70 torch for evaluation, typically for a reasonable charge.

10. Does Changzhou Inwelt offer OEM/ODM services for the LT70 torch?

Yes, Changzhou Inwelt provides comprehensive OEM/ODM services, allowing for customization and private labeling of the LT70/LTM70-CB plasma cutting torch to meet specific business requirements.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių