TW400 Gas Cooled MIG Welding Torch

The TW400 Gas Cooled Mig Welding Torch from Changzhou Inwelt is a high-performance welding tool designed for professionals and hobbyists. Rated at 400 amps at a 60% duty cycle, this air-cooled MIG welding torch is part of the classic Tweco Series, known for its reliability and durability. Its ergonomic design and robust construction make it ideal for a wide range of welding applications.

"INWELT WELDING” also offers a complete stock of consumables and spare parts for the Tweco range of MIG Welding Guns.

Key Features of the TW400 Welding Gun

Ergonomic Design for Comfort and Control

The TW400 features an interlocking handle with a comfortable pulling angle trigger and high-impact-resistant materials. Its ergonomic design reduces welder fatigue, enhancing precision during extended use.

Top-Loading Contact Tip System

The top-loading design allows for quick and easy replacement of contact tips, minimizing downtime and boosting productivity on the job site.

Tapered Contact Tip Locking System

A secure, tapered locking system ensures contact tips remain firmly in place, eliminating loose tips and reducing weld imperfections for consistent results.

Durable and High-Quality Materials

Built with rubber and nylon casing, the TW400 offers superior durability and stability. Its premium construction ensures reliability even in harsh welding environments.

Versatile Consumables Compatibility

Compatible with Lincoln and Tweco Series nozzles and contact tips, the TW400 is supported by INWELT’s comprehensive stock of consumables and spare parts for easy maintenance.

Benefits of Choosing the TW400 MIG Welding Torch

Enhanced Welding Performance

With its ability to weld aluminum, copper alloys, and stainless steel with minimal oxidation or evaporation loss, the TW400 delivers high-quality welds. Its DC reverse capability provides excellent cathode atomization, improving joint quality for metals like aluminum and magnesium.

Cost-Effective Alternative to TIG Welding

Unlike TIG welding, the TW400 does not require tungsten electrodes, reducing costs while maintaining versatility. It’s a reliable alternative for professional welding tasks.

Increased Productivity and Efficiency

The ergonomic design, quick tip replacement, and secure locking system reduce downtime and enhance workflow, making the TW400 ideal for demanding welding projects.

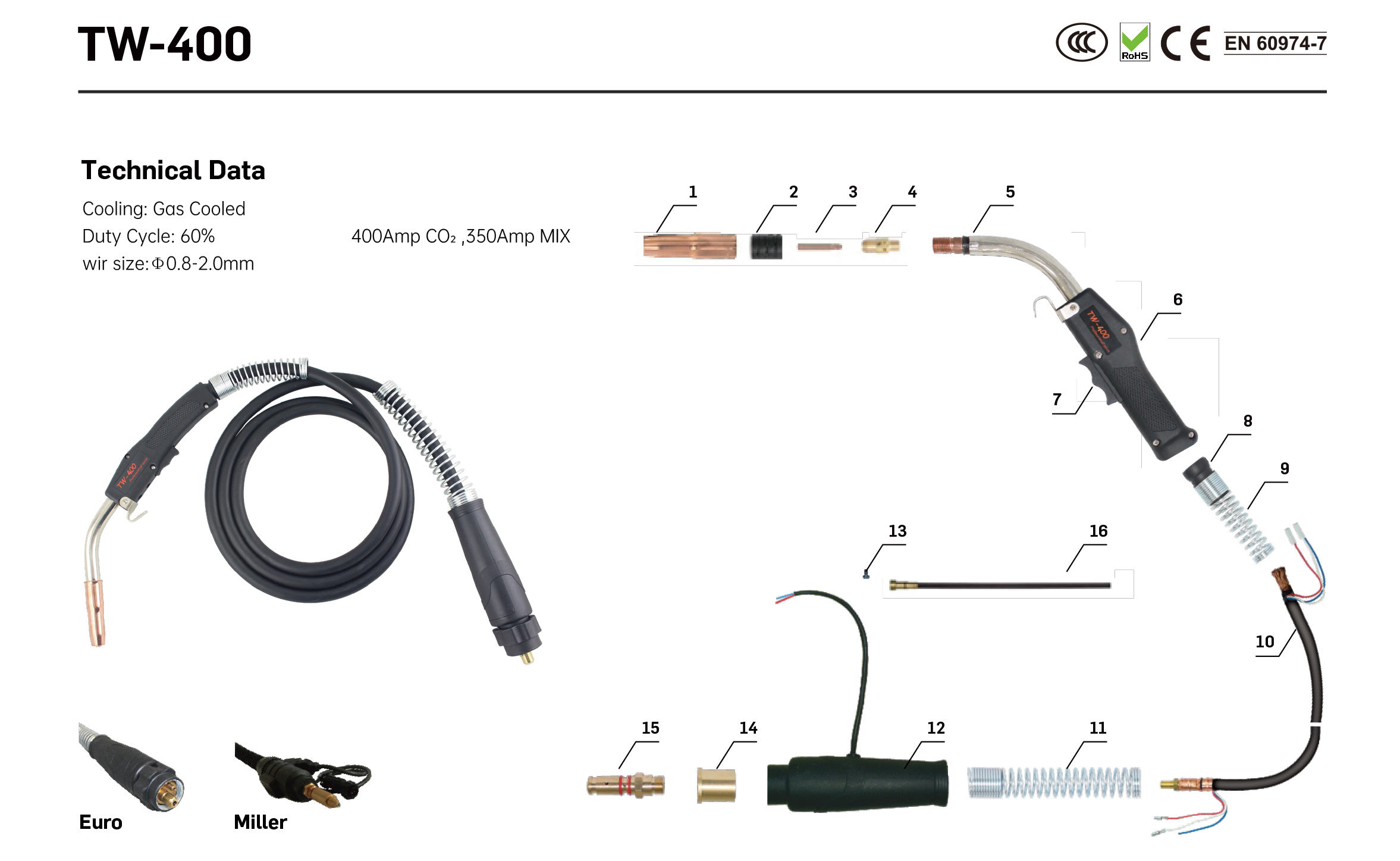

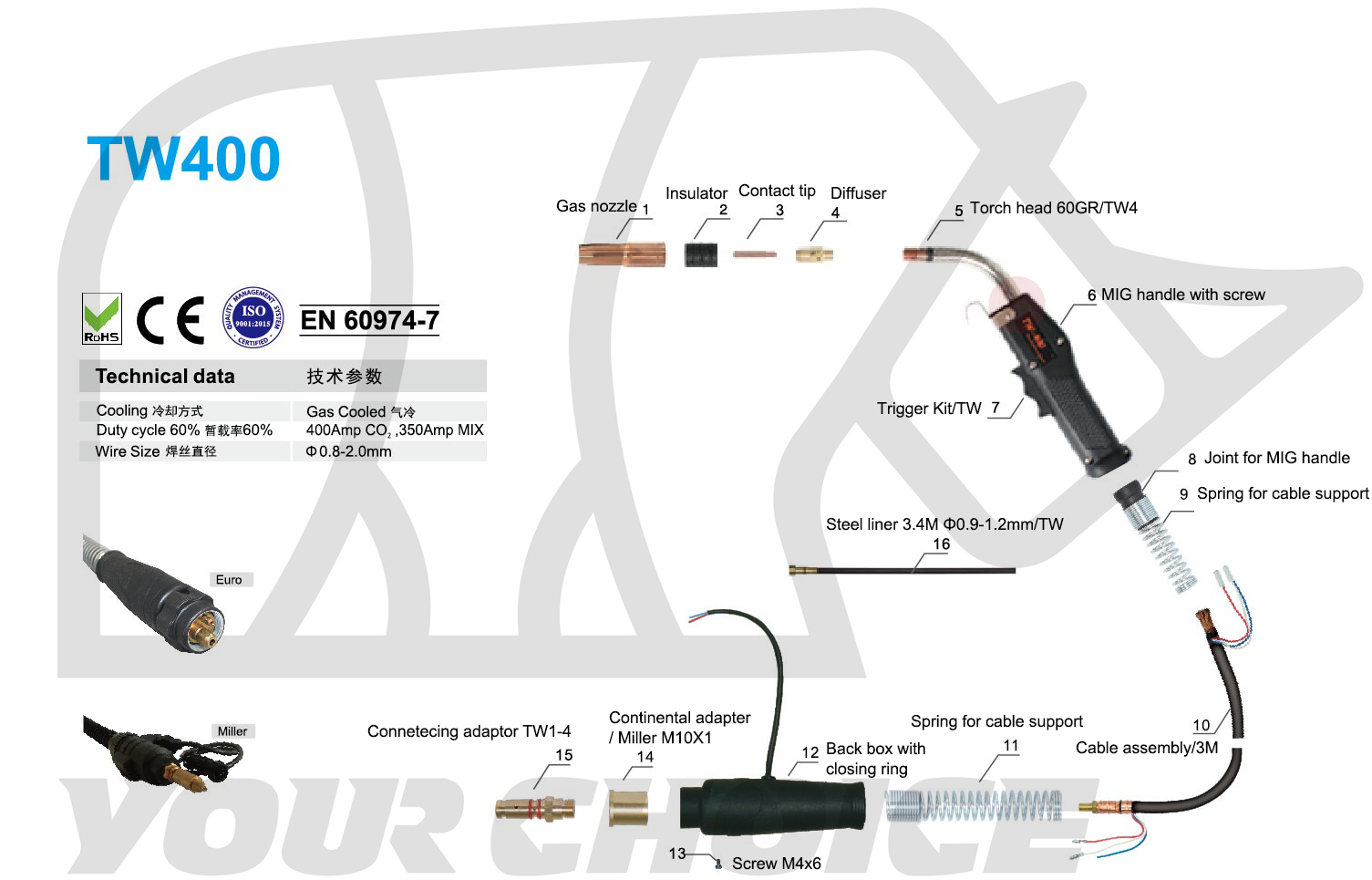

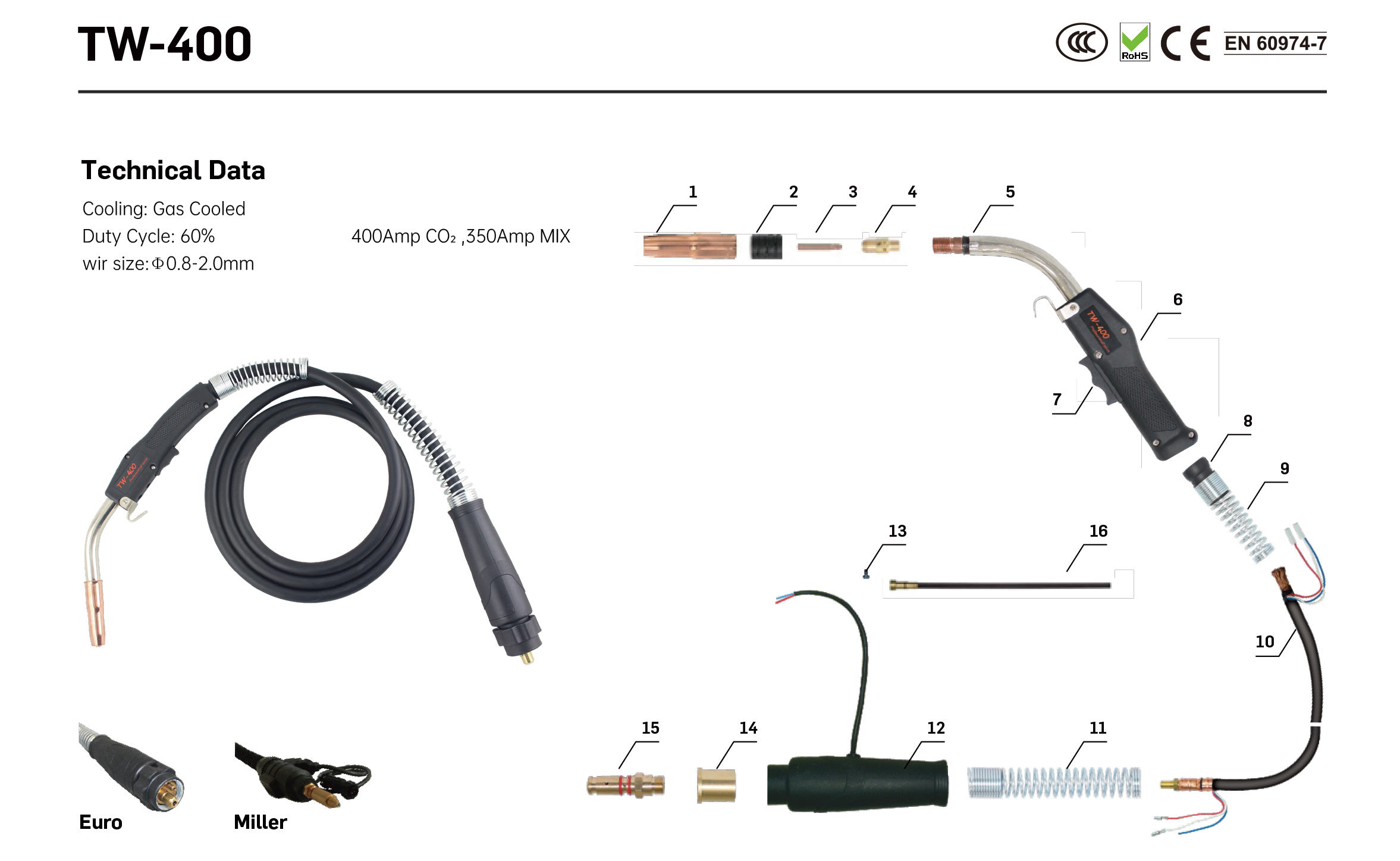

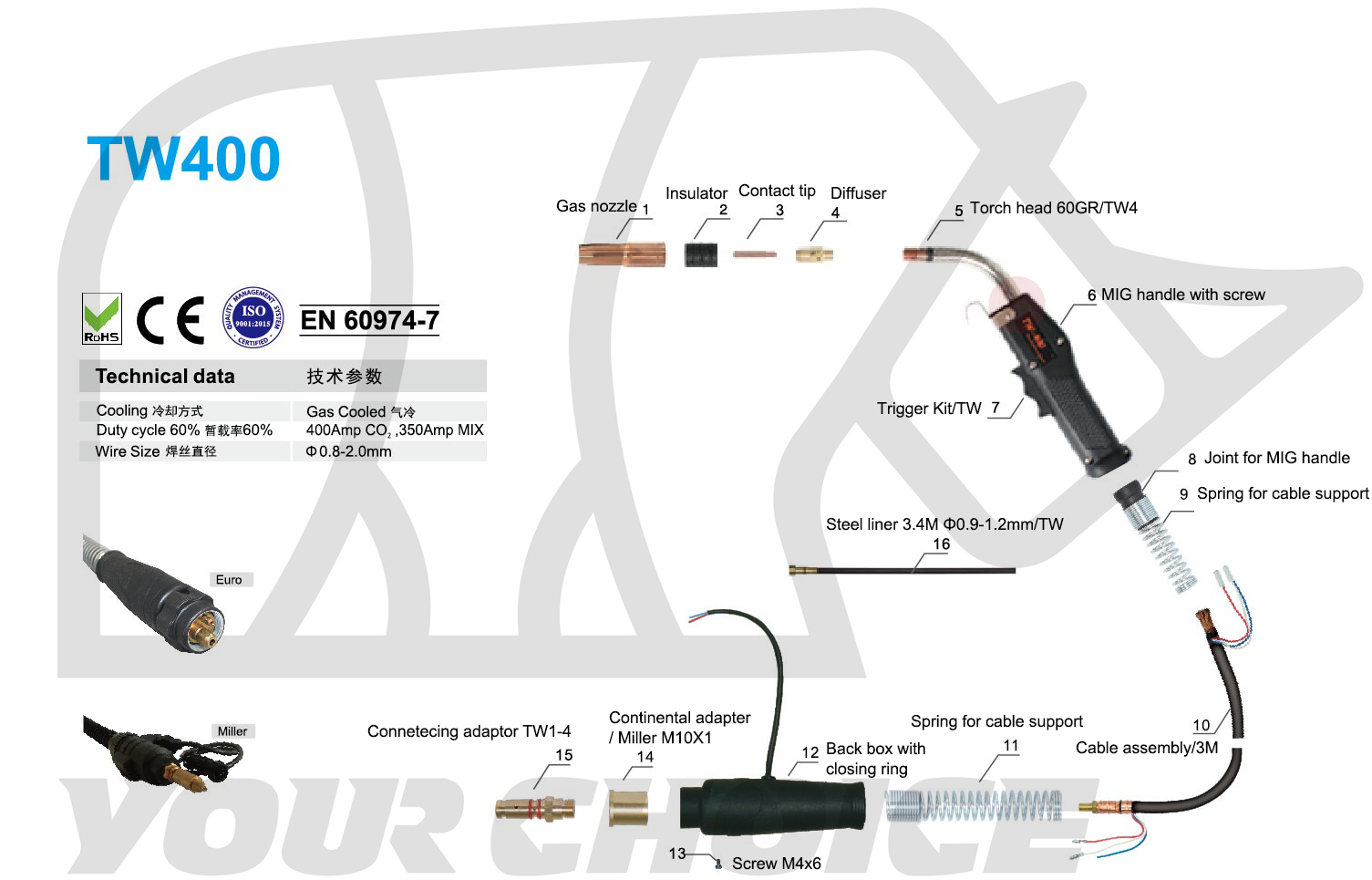

Technical Data:

| Cooling | Gas Cooled | Wire Size | Φ0.8-2.0mm |

| Duty 60% DC | 400Amp CO2, 350Amp MIX | Package | OPP Bag + 1Set/Box |

| Switches | Single | Length | 3m/4m/5m |

| Certificate | CE & Rohs | Gas nozzle | Φ16 mm |

| Position | Code | Ref. | Description |

| 1 | UDT0602 | 24A-62 | Gas nozzle Φ16 |

| 2 | IJDL0697 | 34A | Insulator |

| 3 | IJDV0010-12 | 14-116 | Contact tip Φ1.2mm/ 1/4-28X37.4 |

| 4 | IJDG0081 | 54A | Diffuser |

| 5 | IJDA0600-01 |

| 5 Torch head 60GR/TW4/64J-60/Nickel-plated outer tube |

| 6 | IJDW0704 | 84A | MIG handle with screw |

| 7 | IJIR0092 |

| Trigger Kit/TW |

| 8 | IJIK0788 |

| Joint for MIG handle |

| 9 | IJGU0887-02 |

| Spring for cable support/Zin/Long/TW |

| 10 | IJD00919 |

| Cable assembly/3M |

| 11 | IJGU0835 |

| Spring for cable support/Blue and white zinc plating |

| 12 | IJIK0883 |

| Back box with closing ring |

| 13 | IJGU0074 | EA0018 | Screw M4x6 |

| 14 | IJAI7062 |

| Continental adapter / Miller M10X1 |

| 15 | IJUP0003 |

| Connetecing adaptor TW1-4 |

| 16 | IJJD0010-03 |

| Steel liner 3.4M Φ0.9-1.2mm/TW |

| Complete Torch |

| IJDU5911 | 410-3545 | TW4 Torch 3m |

| IJDU5917 | 412-3545 | TW4 Torch 4m |

| IJDU5918 | 415-3545 | TW4 Torch 4.6m |

| IJDU5926 | X410-3545 | TW4 Torch 3m euro adaptor |

| IJDU5922 | X412-3545 | Tw4 Torch 4m euro adaptor |

| IJDU5923 | X415-3545 | Tw4 Torch 4.6m euro adaptor |

| IJDU5924 | M410-3545 | Tw4 Torch 3m Miller adaptor |

| IJDU5925 | M412-3545 | Tw4 Torch 4m Miller adaptor |

| IJDU5931 | M415-3545 | Tw4 Torch 4.6m Miller adaptor |

Labeled Diagram of TW400 MIG Gun Components

Our comprehensive diagram highlights all critical parts of the TW400 MIG welding gun, including the torch, welder, and gun components. Each part is clearly labeled with descriptions to aid in identification and understanding.

Key Components of the TW400 MIG Welding Gun

Torch Body: The main structure that houses internal components and directs the welding arc.

Nozzle: Directs shielding gas to protect the weld pool from contamination.

Contact Tip: Transfers electrical current to the welding wire for arc creation.

Gas Diffuser: Distributes shielding gas evenly around the weld area.

Trigger: Controls the wire feed and gas flow for precise welding operation.

Handle: Ergonomic grip for comfortable handling during extended use.

Liner: Guides the welding wire from the spool to the contact tip, ensuring smooth feeding.

Neck: Connects the torch body to the nozzle, allowing flexibility and maneuverability.

Power Cable: Supplies electrical current to the torch for welding.

Gas Hose: Delivers shielding gas to the torch for weld protection.

Understanding MIG Welding Gun Parts

The TW400 MIG welding gun is composed of several integral parts that work together to ensure efficient welding performance. Below, we explore the roles of these components in greater detail.

Torch Welding Process

The MIG welding process relies on the TW400’s components to deliver a consistent arc, shielding gas, and wire feed. The torch directs the arc to melt the welding wire, while the shielding gas protects the weld pool from atmospheric contamination, ensuring strong, clean welds.

MIG Welder Gun Parts

In addition to the torch-specific components, the TW400 integrates with the MIG welder system. Key welder gun parts include:

Wire Feed Mechanism: Controls the speed and consistency of the welding wire feed.

Power Supply Connection: Links the gun to the welder’s power source for reliable operation.

Control Switch: Allows the welder to adjust settings like voltage and wire speed directly from the gun.

Applications of the TW400 MIG Welding Torch

The TW400 is suitable for a variety of welding applications, including:

Farm and shop welding projects

Heavy repairs and maintenance

Auto body work and fabrication

Welding aluminum, copper, stainless steel, and other alloys

Technical Specifications

Rating: 400 amps at 60% duty cycle

Cooling: Gas-cooled

Length Options: 3m, 4m, 5m

Consumables: Compatible with Lincoln and Tweco Series nozzles and contact tips

Materials: Rubber and nylon casing, high-quality phosphor bronze switch

Tips for Torch Welding Aluminum with the TW400

Welding aluminum with the TW400 MIG gun requires specific techniques to achieve optimal results. Below are expert tips to enhance your aluminum welding performance:

Preparation for Aluminum Welding

Use the Right Wire: Opt for aluminum-specific welding wire (e.g., ER4043 or ER5356) to ensure compatibility.

Adjust Gas Settings: Use 100% argon as the shielding gas for aluminum welding, as it provides better arc stability.

Clean the Surface: Remove oxides and contaminants from the aluminum surface using a stainless steel brush to prevent weld imperfections.

Welding Techniques

Push Technique: Use a push motion rather than a pull to achieve a cleaner weld bead and better gas coverage.

Control Heat Input: Aluminum conducts heat quickly, so adjust voltage and wire speed to avoid burn-through.

Maintain Consistent Travel Speed: A steady pace ensures uniform welds and prevents overheating.

Maintenance and Upgrades for the TW400 MIG Gun

To keep your TW400 MIG welding gun in top condition, regular maintenance is essential. Inspect components like the contact tip, nozzle, and liner for wear and replace them as needed. Upgrading to high-quality consumables can also enhance performance and extend the gun’s lifespan.

Where to Find Replacement Parts

For replacement parts or upgrades, visit trusted suppliers for recommended vendors. Ensure compatibility with the TW400 model to maintain optimal performance.

Conclusion

The TW400 Gas Cooled MIG Welding Torch & Gun is a versatile tool for professional and hobbyist welders alike. By understanding its labeled components and following best practices for maintenance and aluminum welding, you can achieve superior results. Explore our detailed diagram and tips to master the torch welding process and elevate your welding projects.

Why Choose INWELT WELDING TECH?

INWELT WELDING TECH is a trusted manufacturer and supplier of advanced welding equipment. With a commitment to quality and affordability, INWELT delivers durable, high-performance tools backed by a full range of consumables and spare parts. Contact us at service2@czinwelt.com or WhatsApp at +86-17315080879 for inquiries.

Our Catalog:

INWELT MIG WELDING TORCH.pdf

INWELT MIG WELDING TORCH.pdf

TW400 Gas Cooled MIG Welding Torch FAQs

What is the TW400 MIG Welding Torch used for?

It’s designed for MIG welding, delivering a consistent arc and shielding gas for welding metals like steel and aluminum.

What are the main components of the TW400?

Key parts include the torch body, nozzle, contact tip, gas diffuser, trigger, handle, liner, neck, power cable, and gas hose.

Can the TW400 weld aluminum?

Yes, with aluminum-specific wire (e.g., ER4043), 100% argon gas, and proper settings.

How do I maintain the TW400 MIG Torch?

Regularly inspect and replace worn parts like the contact tip, nozzle, and liner. Clean the torch to prevent debris buildup.

What shielding gas is recommended for the TW400?

Use argon for aluminum or a CO2/argon mix for steel, depending on the material.

How do I replace the contact tip on the TW400?

Power off the welder, remove the nozzle, unscrew the old contact tip, and install a new one compatible with your wire size.

Is the TW400 suitable for heavy-duty welding?

It’s ideal for light to medium-duty welding but may require upgrades for continuous heavy use.

Where can I find replacement parts for the TW400?

Check with authorized suppliers or the manufacturer’s recommended vendors for compatible parts.

What wire sizes are compatible with the TW400?

It supports common wire sizes like 0.023", 0.030", and 0.035", depending on the contact tip and liner.

How do I troubleshoot wire feed issues with the TW400?

Check the liner for blockages, ensure proper tension on the wire feed rollers, and verify the contact tip isn’t worn.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių