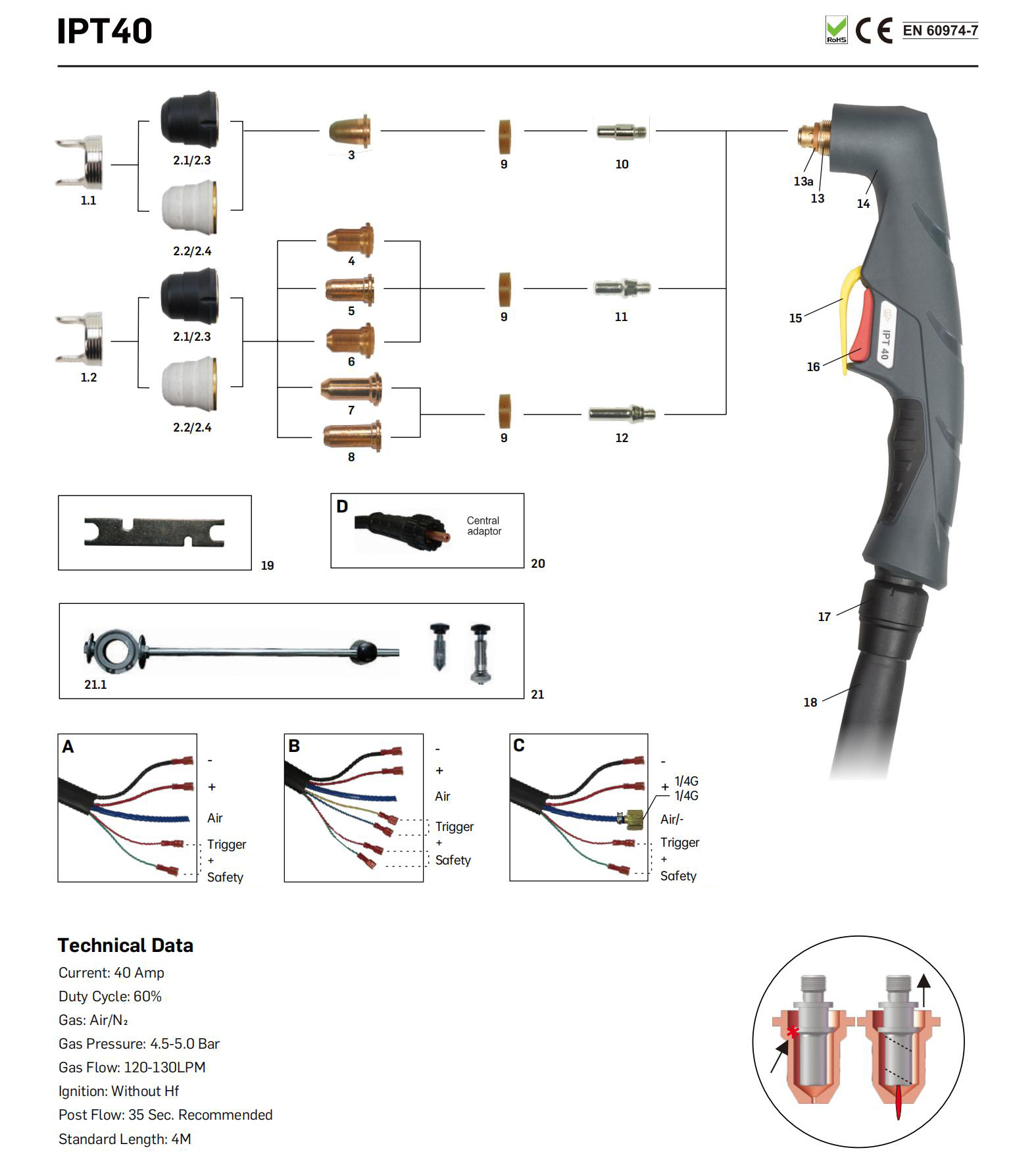

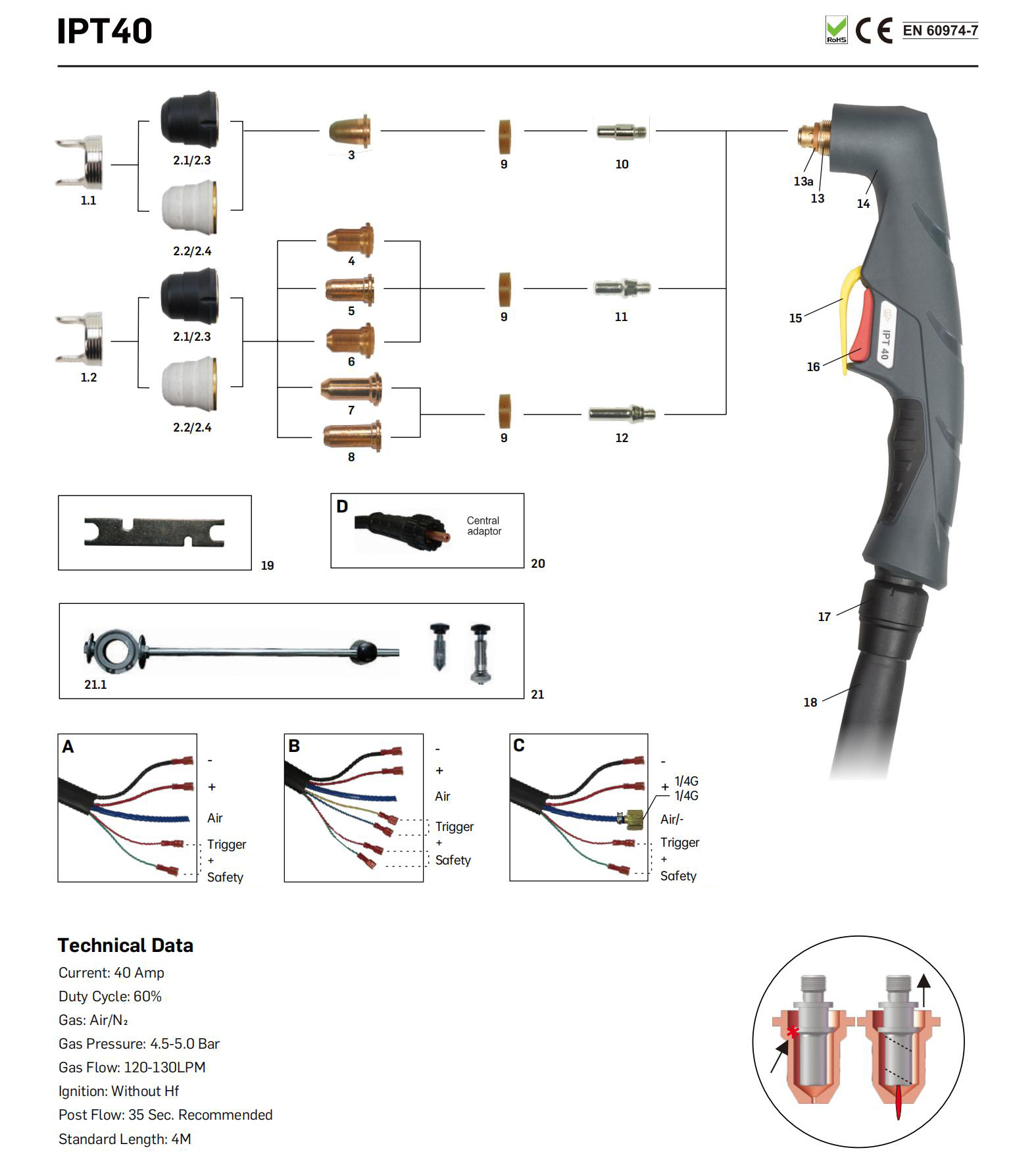

IPT40 Plasma Cutting Torch

The IPT40 Plasma Cutting Torch Gun from Changzhou Inwelt is a high-performance, ergonomic tool designed for precision cutting. Engineered for operator comfort and efficiency, this plasma torch is compatible with standard 60A plasma cutting machines, such as the Cut40, and offers reliable arc initiation without high-frequency (HF) ignition. Whether you're a professional welder or a DIY enthusiast, the IPT40 delivers exceptional results for cutting materials with thicknesses of 8mm to 12mm at 40A.

Why Choose the IPT40 Plasma Cutting Torch?

The IPT40 is a popular choice among professionals due to its advanced features, durability, and ease of use. Built with high-quality materials and cutting-edge technology, this plasma cutting torch ensures consistent performance and longevity. Below are the key reasons why the IPT40 stands out in the market.

Superior Ergonomics and Operator Comfort

The IPT40 Plasma Cutting Torch is designed with operator comfort in mind. Its lightweight construction and ergonomic grip reduce fatigue during extended use, making it ideal for both small-scale projects and heavy-duty industrial applications. The torch features a trigger safety cover to prevent accidental activation, enhancing user safety and control.

Reliable Performance Without HF Ignition

Unlike traditional plasma torches that rely on high-frequency ignition, the IPT40 uses a non-HF arc starting mechanism. This feature simplifies arc initiation, reduces wear on consumables, and ensures a stable cutting process, even in challenging environments. The torch is optimized for clean, precise cuts on various metals, including steel, stainless steel, and aluminum.

Compatibility with 60A Plasma Cutting Machines

The IPT40 is fully compatible with standard 60A plasma cutting machines, such as the Cut40. This compatibility makes it a versatile addition to any workshop, allowing seamless integration with existing equipment. Whether you're upgrading your current setup or building a new one, the IPT40 is a reliable choice.

Key Features of the IPT40 Plasma Cutting Torch

The IPT40 is packed with features that enhance its performance and usability. Here’s a detailed look at what makes this plasma cutting torch a top pick for professionals.

High-Quality Consumables Included

The IPT40 comes with a set of high-quality consumables, ensuring you can start cutting right away. These consumables are designed to withstand high temperatures and prolonged use, reducing the need for frequent replacements and lowering operational costs.

Precision Cutting for Various Materials

Capable of cutting materials with thicknesses ranging from 8mm to 12mm at 40A, the IPT40 delivers clean and accurate cuts. Its advanced plasma technology ensures minimal slag and smooth edges, making it suitable for applications requiring high precision, such as automotive repair, metal fabrication, and construction.

Trigger Safety Cover for Enhanced Safety

Safety is a priority with the IPT40. The trigger safety cover prevents unintended activation, reducing the risk of accidents in busy work environments. This feature is particularly valuable for novice users or those working in high-pressure settings.

» The IPT40 Without High Frequency Air Plasma Cutter Torch cutting 8MM-12MM thick plate under 40A.

» The IPT40 torch include consumables comes with one set of consumables (1 nozzle, 1 electrode, 1 swirl ring, 1 shield cup) installed on torch head, can be use directly

» The IPT40 plasma torch can work with 40A plasma cutting machine such as CUT40 etc

» Make people feel comfortable in the hand when the IPT40 plasma torch is fitted with a high density plastic handle

Technical Specifications

| Current | 40Amp | Gas Flow | 120-130 LPM |

| Duty Cycle | 60% | Ignition | Without HF |

| Gas | Air/N2 | Post Flow | 35 seconds recommended |

| Gas Pressure | 4.5-5.0 Bar | Standard Length | 4M |

Model: IPT40 Plasma Cutting Torch

Compatibility: Standard 60A plasma cutting machines (e.g., Cut40)

Ignition Type: Non-HF arc initiation

Cutting Capacity: 8mm–12mm at 40A

Material: High-quality, heat-resistant components

Safety Features: Trigger safety cover

Applications: Metal fabrication, automotive repair, industrial cutting

Benefits of Using the IPT40 Plasma Cutting Torch

The IPT40 offers several advantages that make it a preferred choice for professionals and hobbyists alike. Here are some of the key benefits:

Ease of Use: The non-HF ignition system simplifies arc starting, making it accessible for users of all skill levels.

Durability: Constructed with premium materials, the IPT40 is built to withstand rigorous use in demanding environments.

Cost-Effective: The included consumables and long-lasting design reduce maintenance costs over time.

Versatility: Suitable for a wide range of applications, from light-duty DIY projects to heavy-duty industrial tasks.

How to Use the IPT40 Plasma Cutting Torch

Using the IPT40 is straightforward, thanks to its user-friendly design. Follow these steps to get started:

Setup: Connect the IPT40 torch to a compatible 60A plasma cutting machine, such as the Cut40.

Safety Check: Ensure the trigger safety cover is engaged and inspect consumables for wear.

Material Preparation: Secure the material to be cut and select the appropriate power settings (up to 40A for 8mm–12mm thickness).

Cutting: Initiate the arc using the non-HF ignition system and guide the torch along the desired cutting path.

Maintenance: Regularly inspect and replace consumables to maintain optimal performance.

Why Buy from Changzhou INWELT?

Changzhou Inwelt is a trusted name in the welding and cutting industry, known for delivering high-quality tools and equipment. When you purchase the IPT40 Plasma Cutting Torch, you benefit from:

Quality Assurance: Each torch is manufactured using advanced processing technology and high-quality raw materials.

Customer Support: Changzhou Inwelt offers reliable customer service to assist with setup, troubleshooting, and maintenance.

Competitive Pricing: Get premium performance at an affordable price, making the IPT40 a cost-effective investment for your workshop.

IPT40 Plasma Cutting Torch Application Areas

The IPT40 Plasma Cutting Torch from Changzhou Inwelt is a versatile, high-performance tool designed for precision cutting across a wide range of industries. Compatible with standard 60A plasma cutting machines like the Cut40, the IPT40 excels in cutting conductive materials such as steel, stainless steel, and aluminum with thicknesses of 8mm to 12mm at 40A. Its ergonomic design, non-HF arc ignition, and durable construction make it ideal for both professional and DIY applications. Below are the key application areas where the IPT40 delivers exceptional results.

Metal Fabrication

The IPT40 is widely used in metal fabrication shops for creating precise cuts in various metals. Its ability to produce clean, smooth edges with minimal slag makes it a preferred choice for fabricators.

Custom Metal Structures

The IPT40 is perfect for crafting custom metal components, such as brackets, frames, and supports. Its precision cutting capabilities ensure accurate shapes and sizes, meeting the demands of bespoke fabrication projects.

Sheet Metal Processing

In sheet metal workshops, the IPT40 is used to cut thin to medium-gauge metal sheets for applications like HVAC systems, roofing, and cladding. The torch’s non-HF ignition ensures consistent performance, even during high-volume production.

Automotive Repair

The automotive industry relies on the IPT40 for repair, modification, and customization of vehicle components. Its versatility and ease of use make it a valuable tool in auto shops.

Body Panel Repairs

The IPT40 is used to cut damaged sections of car body panels for repairs or replacements. Its ability to handle materials up to 12mm thick at 40A allows for precise cuts in steel and aluminum panels, ensuring seamless repairs.

Custom Automotive Fabrication

For custom car builds or modifications, the IPT40 is ideal for creating intricate parts, such as exhaust components, roll cages, or chassis reinforcements. The torch’s ergonomic design reduces operator fatigue during detailed work.

Construction and Demolition

In construction and demolition projects, the IPT40 is used for cutting metal components on-site, offering portability and reliability for demanding environments.

Structural Steel Cutting

The IPT40 is employed to cut steel beams, pipes, and other structural components during construction or demolition. Its non-HF arc ignition ensures safe and stable operation in rugged job sites.

Salvage and Scrap Processing

For demolition and recycling operations, the IPT40 is used to cut scrap metal into manageable sizes for processing or recycling. Its efficiency and durability make it suitable for high-volume cutting tasks.

Industrial Manufacturing

The IPT40 supports various manufacturing processes by providing precise and efficient cutting for industrial applications.

Machinery Component Production

Manufacturers use the IPT40 to produce metal parts for machinery, such as gears, housings, and frames. The torch’s clean cuts reduce the need for additional finishing, streamlining production.

Heavy Equipment Maintenance

In industries like mining or agriculture, the IPT40 is used for maintaining and repairing heavy equipment by cutting replacement parts or removing worn components with precision.

DIY and Hobbyist Projects

The IPT40 is also popular among DIY enthusiasts and hobbyists for its ease of use and versatility in small-scale projects.

Home Workshop Metalwork

For home workshops, the IPT40 is ideal for crafting custom metal projects, such as garden art, furniture, or small sculptures. Its user-friendly non-HF ignition system makes it accessible for beginners.

Automotive and Motorcycle Customization

Hobbyists use the IPT40 to create custom parts for motorcycles or cars, such as brackets, mounts, or decorative panels, allowing for creative and precise modifications.

Spare Parts Details:

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

IPT40 Plasma Cutting Torch FAQs

Q1: What is the IPT40 Plasma Cutting Torch?

The IPT40 Plasma Cutting Torch is a high-performance tool manufactured by Changzhou Inwelt, designed for precision cutting of metals such as steel, stainless steel, and aluminum. It is compatible with standard 60A plasma cutting machines, like the Cut40, and features a non-HF arc ignition system for reliable performance.

Q2: What materials can the IPT40 cut?

The IPT40 can cut a variety of conductive materials, including mild steel, stainless steel, aluminum, and other metals. It is capable of cutting thicknesses ranging from 8mm to 12mm at 40A, depending on the material and power settings.

Q3: Is the IPT40 compatible with my plasma cutting machine?

The IPT40 is designed to work with standard 60A plasma cutting machines, such as the Cut40. To ensure compatibility, check your machine’s specifications or contact Changzhou Inwelt’s customer support for assistance.

Q4: What is non-HF arc ignition, and why is it beneficial?

Non-HF (non-high-frequency) arc ignition simplifies the arc-starting process by eliminating the need for high-frequency signals. This reduces wear on consumables, enhances safety, and ensures stable performance, making the IPT40 easier to use, especially in environments sensitive to electrical interference.

Q5: What consumables are included with the IPT40?

The IPT40 comes with a set of high-quality consumables, including electrodes and nozzles, designed for durability and optimal cutting performance. These consumables are easy to replace and available for purchase from Changzhou Inwelt.

Q6: How do I maintain the IPT40 Plasma Cutting Torch?

To maintain the IPT40, regularly inspect consumables for wear and replace them as needed. Keep the torch clean and free of debris, and store it in a dry, safe environment. Refer to the user manual for detailed maintenance instructions.

Q7: What safety features does the IPT40 have?

The IPT40 includes a trigger safety cover to prevent accidental activation, enhancing user safety. Additionally, its ergonomic design reduces operator fatigue, and the non-HF ignition system minimizes electrical risks during operation.

Q8: What is the cutting capacity of the IPT40?

At 40A, the IPT40 can cut materials with thicknesses of 8mm to 12mm, depending on the material type and cutting conditions. For best results, adjust the power settings on your plasma cutting machine to match the material thickness.

Q9: Can beginners use the IPT40 Plasma Cutting Torch?

Yes, the IPT40 is user-friendly and suitable for both beginners and professionals. Its non-HF ignition system simplifies arc starting, and the ergonomic design makes it easy to handle. However, proper training and safety precautions are recommended for all users.

Q10: Where can I purchase the IPT40 Plasma Cutting Torch?

You can purchase the IPT40 Plasma Cutting Torch directly from Changzhou INWELT ’s website or authorized distributors. For more information on pricing and availability, visit their official website or contact their customer support team.

Q11: How do I contact Changzhou Inwelt for support?

For support, you can reach Changzhou INWELT through their official website’s contact page or customer service hotline. They offer assistance with setup, troubleshooting, and replacement parts for the IPT40 Plasma Cutting Torch.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių