IPTM100 CNC Plasma Cutting Torch for Precision CNC Machines

Overview of the IPTM100 Plasma Cutting Torch

The IPTM100 Plasma Cutting Torch by INWELT is a high-performance, air-cooled cutting solution designed for 100A CNC plasma cutting machines. Engineered for precision and durability, this torch is ideal for industrial applications, offering reliable arc starting without high-frequency (HF) ignition. Compatible with standard 100A CNC plasma cutting systems, the IPTM100 delivers clean cuts on materials up to 30–40 mm thick, making it a versatile choice for metal fabrication, automotive, and manufacturing industries.

Key Features of the IPTM100 Plasma Cutting Torch

No HF Ignition: Ensures easy and safe arc starting, reducing electromagnetic interference and improving operator safety.

Air/N2 Cooling System: Efficient air or nitrogen cooling enhances torch longevity and performance during extended use.

100A Cutting Capacity: Capable of cutting 30–40 mm thick plates with precision under 100A–120A power settings.

Durable Consumables: Includes a set of high-quality consumables for consistent cutting performance and reduced maintenance costs.

6M Torch Length: Provides flexibility and reach for large-scale CNC plasma cutting projects.

Technical Data:

| Current | 100Amp | Gas Flow | 200LPM |

| Duty Cycle | 60% | Ignition | Without HF |

| Gas | Air/N2 | Post flow | 100 seconds recommended |

| Gas Pressure | 4.5-5.0 Bar | Standard Length | 6M |

Why Choose the IPTM100 for CNC Plasma Cutting?

The IPTM100 stands out for its compatibility with standard CNC plasma cutting machines and its robust design tailored for high-demand environments. Its non-HF ignition system simplifies operation while maintaining cutting precision, making it suitable for both small workshops and large industrial setups. The air-cooled design minimizes downtime, ensuring continuous productivity.

Benefits for Industrial Applications

Enhanced Precision: Delivers clean, accurate cuts for intricate designs and heavy-duty materials.

Cost-Effective Operation: Long-lasting consumables and efficient cooling reduce operational costs.

Versatile Compatibility: Seamlessly integrates with 100A CNC plasma cutting systems for diverse applications.

User-Friendly Design: Simplified arc starting enhances usability for operators of all skill levels.

Applications of the IPTM100 Plasma Torch

The IPTM100 is ideal for a range of industries, including:

Metal Fabrication: Perfect for cutting steel, aluminum, and other metals with precision.

Automotive Repair: Suitable for custom fabrication and repair tasks.

Industrial Manufacturing: Supports large-scale production with consistent cutting quality.

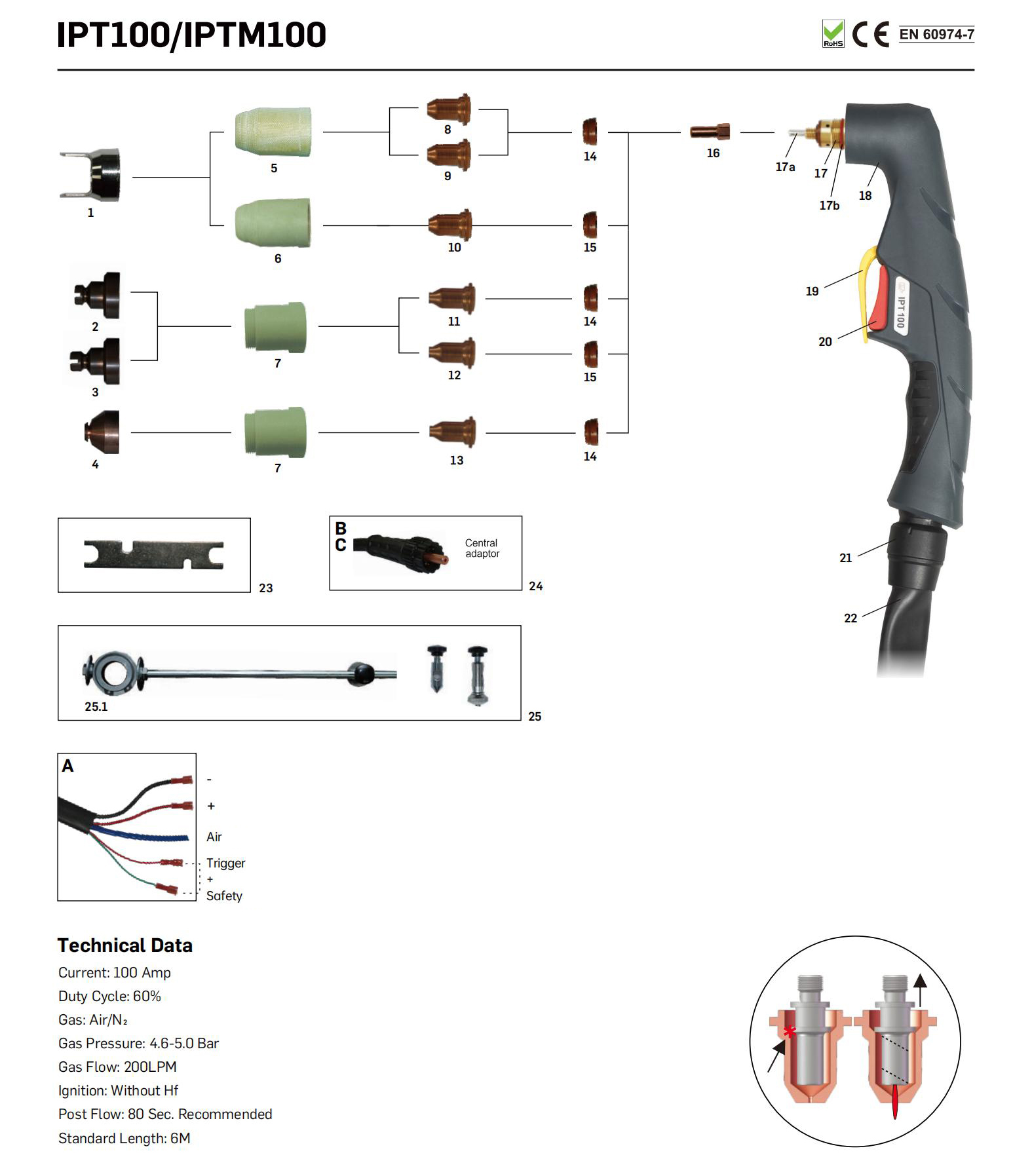

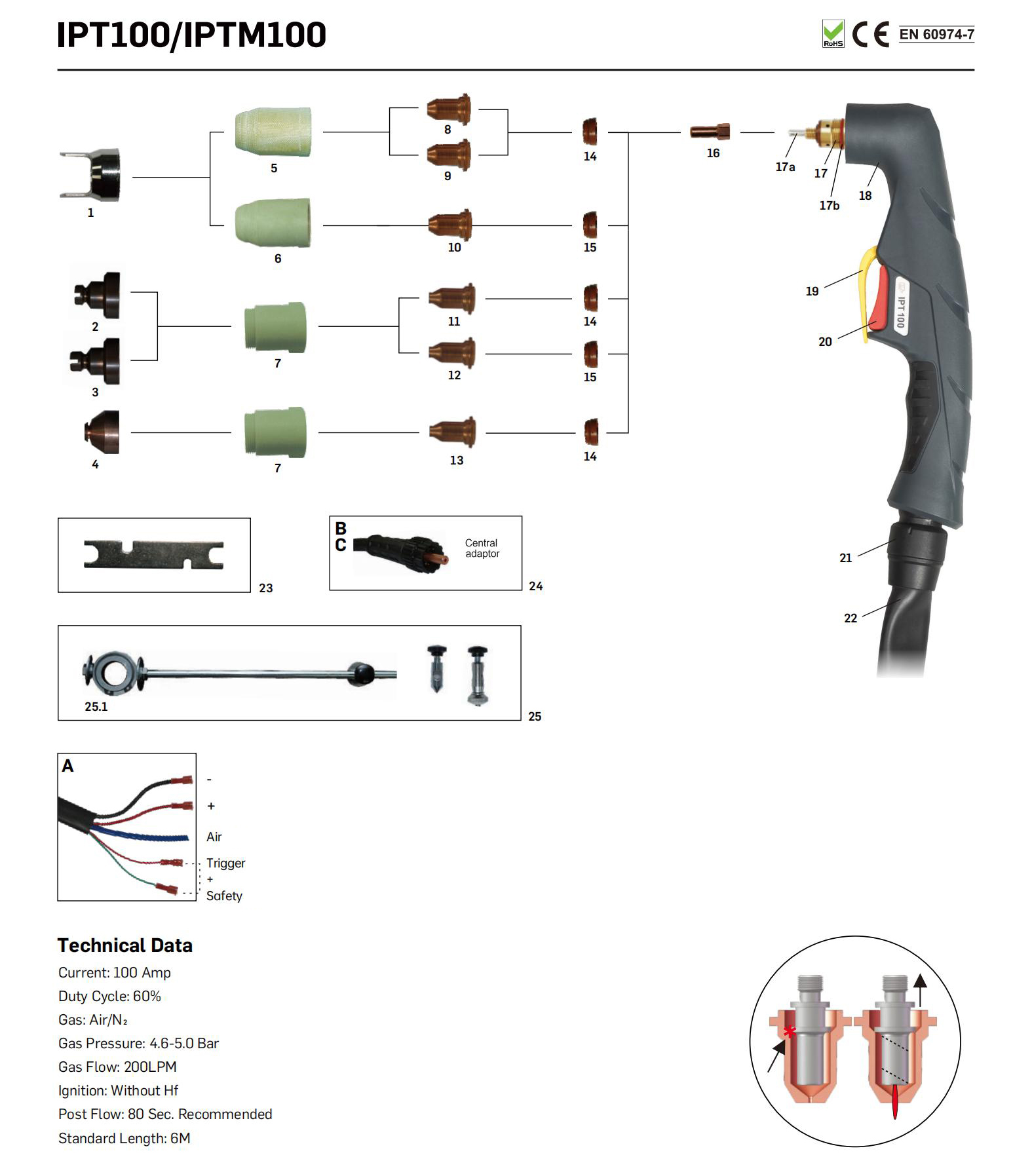

Spare Parts Details:

| Position | Code | Ref. | Description |

| (With " ●" is the standard configuration) |

|

| 1 | IJTN0096 | 60444 | Double pointed spacer/IPT100 |

| 2 | IJTN0711 | 60504 | Shield cap/40-70A/cotact cutting |

| 3 | IJTN0655 | 60505 | Shield cap/80-120A/cotact cutting |

| 4 | IJTN1075 | 60508 | Shield cap/gouging |

| 5 | IJWT1689-05 | 60500 | Outside IPT100/30-70A/Gray glass fiber |

| 6 ● | IJWT1687-05 | 60501 | Outside nozzle IPT100/80-120A/Gray glass fiber |

| 7 | IJWT1685-05 | 60502 | Outside nozzle IPT100/Contact cut and gouging |

| 8 | IJWV1683-09 | 51245.09 | Tip Φ0.9mm/cotact cutting/30-70A /back striking |

| 9 | Tip |

| 9.1 | IJWV1689-10 | 51246.10 | Tip Φ1.0mm/40-50A/ IPT100/back striking |

| 9.2 | IJWV1689-11 | 51246.11 | Tip Φ1.1mm/50-60A/ IPT100/back striking |

| 9.3 | IJWV1689-12 | 51246.12 | Tip Φ1.2mm/60-70A/ IPT100/back striking |

| 10 | Tip |

| 10.1 | IJWV1687-14 | 51248.14 | Tip Φ1.4mm/80-90A/ IPT100/back striking |

| 10.2 | IJWV1687-15 | 51248.15 | Tip Φ1.5mm/100-110A/ IPT100/back striking |

| 10.3 ● | IJWV1687-16 | 51248.16 | Tip Φ1.6mm/110-120A/ IPT100/back striking |

| 11 | Tip |

| 11.1 | IJWV1685-10 | 51276.10 | Contact tip Φ1.0mm/40-50A/IPT100/back striking |

| 11.2 | IJWV1685-11 | 51276.11 | Contact tip Φ1.1mm/50-60A/IPT100/back striking |

| 11.3 | IJWV1685-12 | 51276.12 | Contact tip Φ1.2mm/60-70A/IPT100/back striking |

| 12 | Tip |

| 12.1 | JWV1697-14 | 51278.14 | Contact tip Φ1.4mm/80-90A/IPT100/back striking |

| 12.2 | IJWV1697-15 | 51278.15 | Contact tip Φ1.5mm/100-110A/IPT100/back striking |

| 12.3 | IJWV1697-16 | 51278.16 | Contact tip Φ1.6mm/110-120A /IPT100/back striking |

| 13 | IJWV1698-22 | 51278G.22 | Tip gouging IPT100/120A/gouing/back striking |

| 14 | IJWG1673 | 60025 | Diffuser IPT100/30-70A |

| 15 | IJWG1672 | 60026 | Diffuser IPT100/80-120A and gouging |

| 16 ● | IJWC1687 | 52556 | Electrode plasma IPT100 |

| 17 | JWA0056-01 |

| Plasma torch head IPT100/90° |

| 17a | IJAO0785 | 09700.48 | Air tube IPT100 |

| 17b | IJGU0716 | 51190.41 | "O"ring Φ18x21mm IPT100 |

| 18 | IJHW0042-01 |

| Plasma handle manual/IPT80-100/Red |

| 19 | IJIK0733 |

| Protection part/plasma/yellow |

| 20 | IJIR0081 |

| Trigger |

| 21 | IJIK0804 |

| Joint/small/new type |

| 22 | Cable assembly |

| 22.1 | IJWO01210074-300 | Cable assembly/IPT100/6M/2 wires/integrated |

| 22.2 | IJWO01210134-300 | Cable assembly/IPT100/12M/2 wires/integrated |

| 22.3 | IJWO01210071-300 | Cable assembly/IPT100/6M/2 wires/centre adaptor |

| 22.4 | IJWO01210131-300 | Cable assembly/IPT100/12M/2 wires/centre adaptor |

| 22.5 | IJWO01210077-300 | Cable assembly/IPT100/6M/4 wires/centre adaptor |

| 22.6 | IJWO01210137-300 | Cable assembly/IPT100//12M/4 wires/centre adaptor |

| 23 IJDH6017 Spanner for Plasma |

| 24 IJAY0089 Central adaptor torch side plasma 5 pins |

| 25 | IJTN0716 | Circle | cutting | attachment/IPT100 |

| 25.1 IJTN0683 Roller stand IPT100/ with spanner |

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

FAQs About the IPTM100 Plasma Cutting Torch

1. What is the cutting capacity of the IPTM100 Plasma Cutting Torch?

The IPTM100 is designed for 100A–120A CNC plasma cutting machines and can cut metal plates up to 30–40 mm thick with precision, depending on the material and power settings.

2. Is the IPTM100 compatible with my CNC plasma cutting machine?

The IPTM100 is compatible with standard 100A CNC plasma cutting systems. Please verify your machine’s specifications or contact INWELT to ensure compatibility.

3. Does the IPTM100 use high-frequency (HF) ignition?

No, the IPTM100 features a non-HF ignition system, which simplifies arc starting, reduces electromagnetic interference, and enhances operator safety.

4. What type of cooling does the IPTM100 Plasma Torch use?

The IPTM100 uses an air/N2 (nitrogen) cooling system, which ensures efficient heat dissipation and extends the torch’s lifespan during extended use.

5. What consumables are included with the IPTM100, and how long do they last?

The IPTM100 comes with a set of durable consumables. Lifespan varies based on usage intensity, but INWELT’s high-quality consumables are designed for long-lasting performance. Replacement consumables are available for purchase.

6. What materials can the IPTM100 Plasma Torch cut?

The IPTM100 is suitable for cutting a variety of metals, including steel, stainless steel, aluminum, and other conductive materials, making it ideal for metal fabrication, automotive, and industrial applications.

7. How long is the IPTM100 Plasma Torch cable?

The IPTM100 comes with a 6-meter torch cable, providing ample reach for large-scale CNC plasma cutting projects.

8. How do I maintain the IPTM100 Plasma Cutting Torch?

Regular maintenance includes checking and replacing consumables as needed, ensuring proper air/N2 cooling flow, and keeping the torch clean. Refer to the user manual or contact INWELT for detailed maintenance guidelines.

9. Where can I purchase the IPTM100 Plasma Cutting Torch or its consumables?

You can inquire about the IPTM100 and its consumables directly through INWELT’s official website or contact their sales team for pricing and availability.

10. What makes the IPTM100 different from other plasma cutting torches?

The IPTM100 stands out for its non-HF ignition, air/N2 cooling, and compatibility with 100A CNC systems. Its durable design and 6-meter cable make it a reliable choice for precision cutting in demanding industrial environments.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių