IPT60 Plasma Cutting Torch

It is the popular IPT60 Plasma Cutting Torch. Without HF Ignition, easy to start arc. It is compatible with standard of 60A Plasma Cutting Machine. (i.e. CUT60, CUT70.) The Brand of machines would be Rilon, Riland, Jasic, Mitech, Chiry, UNT, Krypton, Longetivity and so on. The IPT60 Plasma Cutting Torch is a widely recognized and versatile cutting tool used with plasma cutting machines. It's designed to efficiently cut various types of metal, including steel, stainless steel, aluminum, brass, and copper.

IPT60 Plasma Cutting Torch: Key Features

Pilot Arc Start: Many IPT60 torches feature a pilot arc. This means the torch can start the arc without needing to touch the workpiece, which is excellent for cutting expanded metal, rusty, or painted surfaces, and extends consumable life.

Non-High Frequency (Non-HF) Ignition (Common): A significant number of IPT60 torches use a blow-back start mechanism rather than a high-frequency (HF) start. This reduces electromagnetic interference (EMI), making it safer for use around sensitive electronics, computers, and CNC equipment.

Balanced Power & Precision: The IPT60 is designed to handle common metal thicknesses (typically up to 5/8" to 3/4" production cut) while still offering relatively precise and clean cuts, making it versatile for various tasks.

Widespread Compatibility: It's a very common torch model, found on many 40A to 60A plasma cutters from different manufacturers. This often means consumables are readily available and reasonably priced.

Durable Design: Built to withstand the rigors of metal fabrication, IPT60 torches are generally robust, offering good longevity with proper maintenance.

Technical Data:

| Current | 60Amp | Gas Flow | 120-130LPM |

| Duty Cycle | 60% | Ignition | Without HF |

| Gas | Air/N2 | Post Flow | 55 seconds recommended |

| Gas Pressure | 4.5-5.0 Bar | Standard Length | 6M |

IPT60 Plasma Cutting Torch: Key Application Scenarios

The IPT60 Plasma Cutting Torch is a versatile tool, perfect for a range of metal-cutting tasks.

Automotive Repair & Customization: Ideal for cutting out rusted body panels, fabricating custom brackets, or modifying exhaust systems.

DIY & Home Workshop Projects: Great for building metal furniture, creating artistic metal decor, or fabricating custom parts for home improvements.

Light Industrial Fabrication: Used in smaller shops for cutting materials for railings, gates, structural components, and various custom metalwork.

Artistic Metalwork & Sculpture: Enables artists to make intricate cuts and detailed designs for sculptures, signs, and other decorative pieces.

Farm & Ranch Maintenance: Perfect for quick repairs to farm equipment, fences, and other metal structures on site.

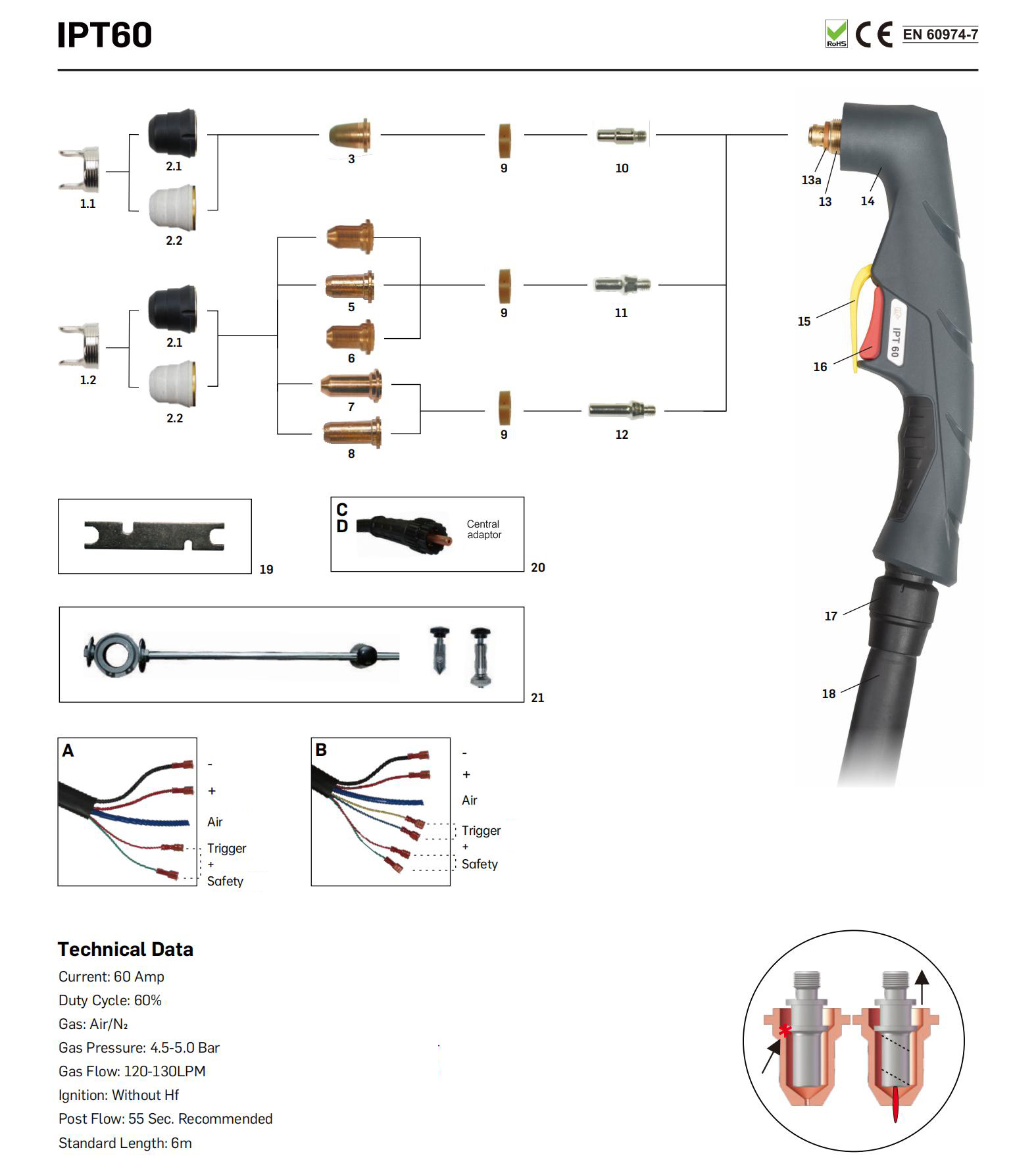

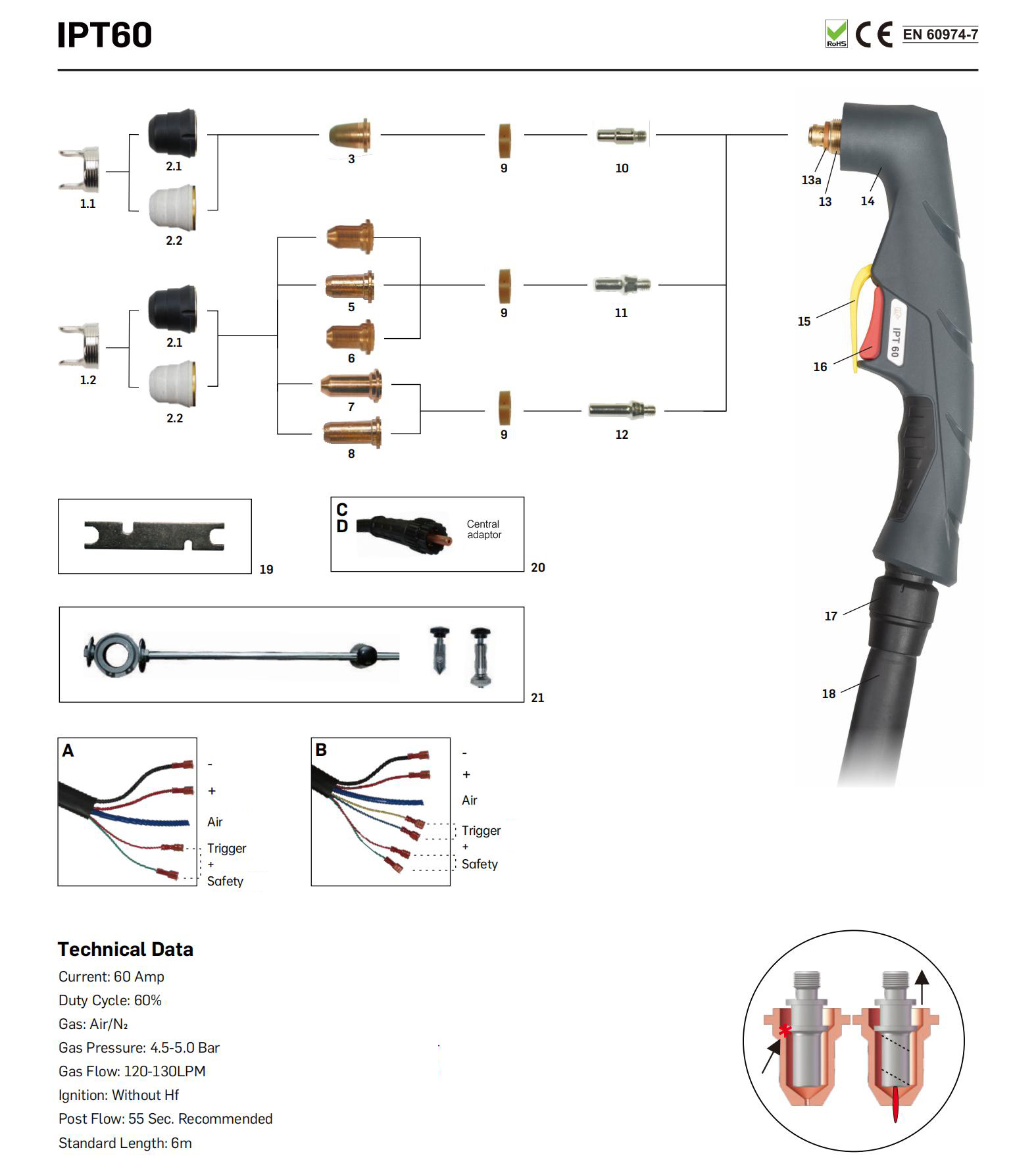

Spare Parts Details:

| Complete Torch |  |

| Code | Description |

| A | IJWU03052 | Plasma torch IPT60/6M 1/4G/integrated/2 wries |

| A | IJWU03052-00 | Plasma torch IPT60/6M 1/4G/integrated/2 wries/back striking |

| B | IJWU03053 | Plasma torch IPT60/6M 1/4G/separate/2 wries |

| B | IJWU03053-00 | Plasma torch IPT60/6M 1/4G/separate/2 wries/back striking |

| C | IJWU03054 | Plasma torch IPT60/6M/central adaptor/2 wries |

| C | IJWU03054-00 | Plasma torch IPT60/6M/central adaptor/2 wries/back striking |

| D | IJWU030441 | Plasma torch IPT60/6M/central adaptor/4 wries |

| D | IJWU030441-00 | Plasma torch IPT60/6M/central adaptor/4 wries/back striking |

(带“ ●”为标准配置 / With " ●" is the standard configuration)

| Position Code | Ref. | Description |

| 1 |

| Double pointed spacer |

| 1.1 | IJTN0009-01 |

| Double pointed spacer/IPT60 |

| 1.2 | IJTN0009 | 60432 | Double pointed spacer/IPT60/backing striking |

| 2 ● |

| Outside nozzle |

| 2.1 | IJWT0672-03 | 60389 | Outside nozzle 6holes IPT60/bakelite |

| 2.2 ● | IJWT1672-05 |

| Outside nozzle 6holes IPT60/Gray Glass fiber |

| 3 |

| Tip |

| 3.1 | IJWV0672-06 | PD0116-06 | Tip Φ0.6mm/10-20A IPT60 |

| 3.2 | IJWV0672-08 | PD0116-08 | Tip Φ0.8mm/20-30A IPT60 |

| 3.3 | IJWV0672-09 | PD0116-09 | Tip Φ0.9mm/30-40A IPT60 |

| 4 |

| Tip |

| 4.1 | IJWV1671-06 | 51318.06 | Tip Φ0.6mm/10-20A IPT60/back striking |

| 4.2 | IJWV1671-08 | 51318.08 | Tip Φ0.8mm/20-30A IPT60/back striking |

| 4.3 | IJWV1671-09 | 51318.09 | Tip Φ0.9mm/30-40A IPT60/back striking |

| 4.4 | IJWV1671-10 |

| Tip Φ1.0mm/40-50A IPT60/back striking |

| 5 | IJWV1678-09 | 51312P.09 | Tip Φ0.9mm/30-40A IPT60/Contact cutting/back striking |

| 6 |

| Tip |

| 6.1 | IJWV1679-10 | 51313P.10 | Flat tip Φ1.0mm/40-50A IPT60/backing striking |

| 6.2 | IJWV1679-11 | 51313P.11 | Flat tip Φ1.1mm/50-60A IPT60/backing striking |

| 7 ● |

| Tip |

| 7.1 | IJWV1610-06 | 51318L.06 | Extended tip Φ0.6mm/10-20A IPT60/backing striking |

| 7.2 | IJWV1610-08 | 51318L.08 | Extended tip Φ0.8mm/20-30A IPT60/backing striking |

| 8 |

|

|

| 8.1 | IJWV1614-09 |

| 51314.09 | Extended tip Φ0.9mm/30-40A IPT60/Contact cutting/backing striking |

| 8.2 | IJWV1614-10 |

|

| Extended tip Φ1.0mm/40-50A IPT60/Contact cutting/backing striking |

| 9 | IJWG1612 |

| 60028 | Diffuser IPT20C-IPT60 |

| 10 | IJWC0671 | PR0110 |

| Electrode Plasma IPT20C-IPT60 |

| 11 | IJWC1059 |

| 52582 | Electrode Plasma IPT20C-IPT60/backing striking |

| 12 | IJWC1050 |

| 52583 | Extended electrode IPT20C-IPT60/backing striking |

| 13 | IJWA0087 |

|

| IPX-45/60 hand torch head |

| 13a | IJGU0710 |

| 51620.60 | "O"ring Φ15XΦ18 IPT60 RED SIL |

| 14 | IJHW0049-01 |

|

| Plasma handle manual/IPT20-60/PX torch head |

| 15 | IJIK0733 |

|

| Protection part/Plasma/Yellow |

| 16 | IJIR0081 |

| 07301.20 | Trigger red |

| 17 IJIK0809 Plasma Joint/IPT20-60 |

| 18 Cable assembly |

| 18.1 IJWO011 06071-22 Cable assembly/IPT60/6M/2 wires/centre adaptor |

| 18.2 IJWO011 06074-22 Cable assembly/IPT60/6M/2 wires/integrated |

| 18.3 IJWO011 06077-22 Cable assembly/IPT60/6M/4 wires/centre adaptor |

| 18.4 IJWO011 06072-22 Cable assembly/IPT60/6M/2 wires/PX torch head/separate |

| 19 IJDH6017 Spanner for Plasma |

| 20 IJAY0089 Central adaptor torch side Plasma 5 pins |

| 21 | IJTN0718 | Circle cutting attachment |

| 21.1 IJTN0684 Roller stand IPT20C-60 / with spanner |

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

IPT60 Plasma Cutting Torch: Frequently Asked Questions

1. What is the IPT60 Plasma Cutting Torch used for?

The IPT60 Plasma Cutting Torch is a versatile tool primarily used for cutting various metals, including mild steel, stainless steel, aluminum, brass, and copper. It's ideal for a range of applications, from DIY projects and automotive repairs to light industrial fabrication and artistic metalwork. Its precision and clean cuts make it a popular choice for detailed work and general metal processing.

2. What are the key features of the IPT60 Plasma Torch?

The IPT60 Plasma Torch typically offers a balance of power and precision. Key features often include a durable design for extended lifespan, efficient cutting capabilities for various metal thicknesses, and compatibility with a wide range of plasma cutting machines. Many IPT60 torches are designed for pilot arc starting, which allows for cutting on rusty or painted surfaces without needing direct contact. They are also known for stable arc performance and excellent consumable life.

3. Is the IPT60 torch compatible with my plasma cutter?

The IPT60 Plasma Cutting Torch is commonly found on a variety of plasma cutters, particularly those with a cutting capacity in the 40-60 amp range. To confirm compatibility, always check your plasma cutter's manual or product specifications to see if it lists IPT60 torch compatibility. You should also verify the connection type (e.g., central connector, 2-pin/4-pin connections for trigger, air, etc.).

4. What consumables does the IPT60 Plasma Torch use?

The IPT60 Plasma Torch uses specific consumables that need to be replaced periodically for optimal performance. These typically include:

Nozzles/Tips: These direct the plasma arc and determine the cut quality and thickness.

Electrodes: These generate the arc.

Swirl Rings: These create the swirling motion of the plasma gas.

Shield Cups/Drag Shields: These protect the nozzle and direct the gas flow, sometimes allowing for drag cutting.

Retaining Caps: These hold the consumables in place. Always ensure you purchase genuine or high-quality compatible IPT60 consumables to maintain cutting efficiency and torch longevity.

5. How do I maintain my IPT60 Plasma Cutting Torch?

Proper maintenance extends the life of your IPT60 torch and ensures consistent performance:

Inspect Consumables Regularly: Check nozzles, electrodes, and shield cups for wear and replace them when they show signs of pitting, enlargement, or damage.

Keep it Clean: Periodically clean the torch body and connections to prevent dust and debris buildup.

Ensure Proper Air Pressure: Always use clean, dry air at the recommended pressure for your plasma cutter, as moisture and contaminants can severely damage consumables and the torch.

Avoid Overheating: Adhere to the duty cycle of your plasma cutter to prevent the torch from overheating.

Store Properly: When not in use, store the torch in a clean, dry environment.

6. What metal thickness can the IPT60 torch cut?

The IPT60 Plasma Cutting Torch is generally rated for cutting various metal thicknesses, depending on the amperage of the plasma cutter it's attached to. For a typical 60-amp plasma cutter, you can expect:

Severance Cut: Up to 1 inch (25mm)

Production Cut: Up to 5/8 inch (16mm)

Clean Cut: Up to 1/2 inch (12mm) Always refer to your specific plasma cutter's specifications for precise cutting capacities, as performance can vary based on machine quality, air pressure, and operator technique.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių