P80 Plasma Cutting Torch

"INWELT WELDING TECH" P80 Plasma Machine Cutting Cutter Torch Head CNC Table Customizable.

This hand torch body is suitable for a P80 plasma cutter torch, nozzle, and electrode With this torch body, convenient to replace the broken during the cutting process and complete the cutting project smoothly.

This hand torch body can be used for P80 P-80 Plasma Cutter torch

Pencil & Straight 0-degree Machine Torch Head Body

Convenient to replace the broken during the cutting process, and complete the cutting project smoothly.

The P80 Plasma Cutting Torch is an excellent choice for metal cutting due to its superior performance and broad applicability. If you're looking for an efficient, durable, and easy-to-operate plasma cutting tool, the P80 is definitely worth considering.

Benefits and Features of the P80 Plasma Cutting Torch

High-Efficiency Cutting: Designed to produce a stable and focused plasma arc, the P80 ensures fast, high-efficiency metal cutting, boosting productivity.

Strong Cutting Capability: It's suitable for cutting a variety of conductive metals, including stainless steel, carbon steel, aluminum, and copper, across a wide range of thicknesses.

» The P80 High Frequency Air Plasma Cutter Torch cutting 40MM thick plate under the current of 120A.

» Can be used in high frequency contact 60A-120A following up of air plasma arc cutting machine series products, high-frequency air plasma is suitable for various brands of 60A-120A following cutting machine.

» The Brand of Machine would be Rilon, Riland, Jasic, Mitech, Chiry, UNT, Krypton, Longetivity, Berlan, Tonsense and so on

» These torches for Plasma cutting machines such as CUT-50, CUT-100, CUT-120, CUT-80, CUT-60, LGK-60, LGK-80, LGK100, LGK-120, etc.

Technical Data:

Current | 80Amp | Gas Flow | 220LPM |

Duty Cycle | 60% | Ignition | HF |

Gas | Air | Post flow | 80 seconds recommended |

Gas Pressure | 4.5-5.0 Bar | Standard Length | 5M |

Applications of the P80 Plasma Cutting Torch

The P80 Plasma Cutting Torch is extensively used in:

Metal Manufacturing & Fabrication: Shipbuilding, automotive manufacturing, structural steelwork, and general machinery.

» General engineering

» Construction industries

» Power cycle

» Railway industries

» Heavy duty industry

Factors to Consider When Choosing a P80 Plasma Cutting Torch

When selecting a P80 Plasma Cutting Torch, keep these points in mind:

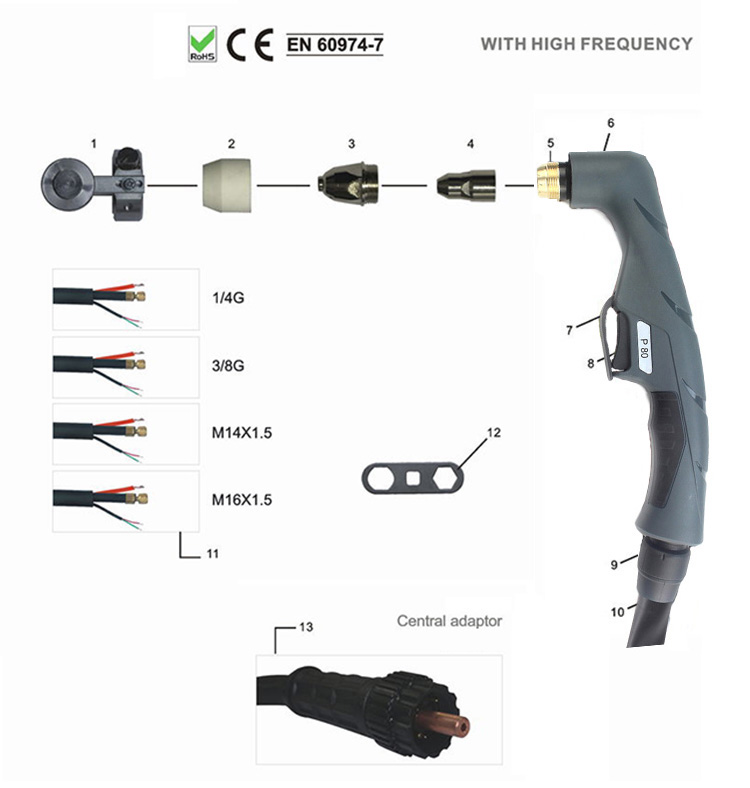

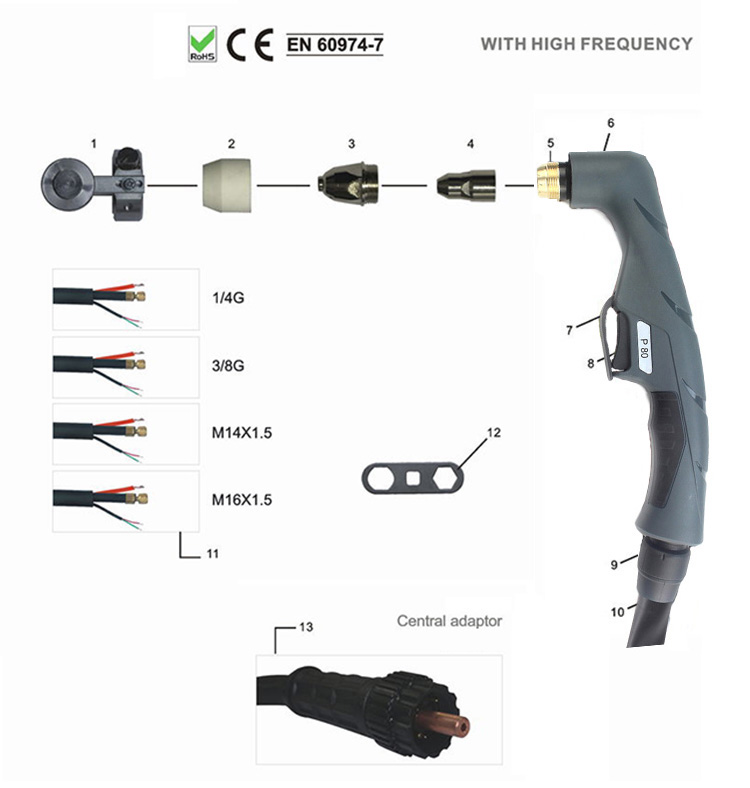

Spare Parts Details:

Code |  Description Description

|

|

|

IJWU0658 | Plasma cutting | torch/p80/10m | /5m center adaptor |

IJWU0657 | Plasma cutting | torch/p80/10m | /5m 3/8G |

IJWU0996 | Plasma cutting | torch/p80/10m | /5m M16x1.5 |

IJWU0992 | Plasma cutting | torch/p80/10m | /5m 1/4G |

IJWU0993 | Plasma cutting | torch/p80/10m | /5m M14x1.5 |

IJWU8111 | Plasma cutting | torch/p80/16m | /5m M16x1.5 |

IJWU8112 | Plasma cutting | torch/p80/16m | /5m M14x1.5 |

IJWU8113 | Plasma cutting | torch/p80/14m | /5m M16x1.5 |

IJWU8114 | Plasma cutting | torch/p80/12m | /5m M16x1.5 |

|

Position | Code | Ref. | Description |

1 | IJTN0710 |

| Isolated wheel/p80 |

2 | IJWT0024 | TGN02004 | Ceramic outside nozzle/p80 |

3 |

|

| Tip |

3.1 | IJWV0040-10 | TET01110 | Tip Φ1.0mm P80 |

3.2 | IJWV0040-13 | TET01130 | Tip Φ1.0mm P80 |

3.3 | IJWV0040-15 | TET01512 | Tip Φ1.0mm P80 |

4 | IJWC0031 | TET02033 | Electorde/p80 |

5 | IJWA0004 | TKU08103 | Plasma torch head p80/light |

6 | IJHW0046 |

| Plasma handle manuale/aseires/red |

7 | IJIK0733 |

| Protection Part/plasma/yellow |

8 | IJIR0081 |

| Trigger |

9 | IJIK0804 |

| Joint/small/newtype |

10 |

|

| Cable assembly |

10.1 | IJWO00810061-00 |

| Cable assembly/p80/10mmq/5m center adaptor |

10.2 | IJWO00810062-00 |

| Cable assembly/p80/10mmq/5matt.1/4G |

10.3 | IJWO00810063-00 |

| Cable assembly/p80/10mmq/5matt.3/8G |

10.4 | IJWO00810064-00 |

| Cable assembly/p80/10mmq/5m M14*1 |

10.5 | IJWO00810065-00 |

| Cable assembly/p80/10mmq/5m M14*1,5 |

10.6 | IJWO00810066-00 |

| Cable assembly/p80/10mmq/5m M16*1,5 |

10.7 | IJWO10810061-00 |

| Cable assembly/pp80/10mmq/5m center adaptor |

10.8 | IJWO10810062-00 |

| Cable assembly/pp80/10mmq/5matt.1/4g |

10.9 | IJWO10810063-00 |

| Cable assembly/pp80/10mmq/5matt.3/8g |

10.10 | IJWO10810064-00 |

| Cable assembly/pp80/10mmq/5m M14*1,5 |

10.11 | IJWO10810065-00 |

| Cable assembly/pp80/10mmq/5m M14*1,5 |

10.12 | IJWO10810066-00 |

| Cable assembly/pp80/10mmq/5m M16*1,5 |

11 |

|

| Connecting adaptor |

12 | IJDH6010 |

| Spanner for p80 |

13 | IJAY0089 |

| Centre adaptor torchside plasma 5pins |

Our Catalog:

INWELT PLASMA TORCH CATALOG.pdf

INWELT PLASMA TORCH CATALOG.pdf

P80 Plasma Cutting Torch: Your Frequently Asked Questions Answered

Q1: What is a P80 Plasma Cutting Torch?

The P80 Plasma Cutting Torch is a widely used and essential component of a plasma cutting system.It's the part that actually cuts the metal! It works by generating a highly concentrated, superheated stream of plasma, which rapidly melts and blows away metal, allowing for precise and efficient cuts on various conductive materials.

Q2: What metals can the P80 torch cut?

The P80 Plasma Cutting Torch is incredibly versatile and can cut a broad range of conductive metals. This includes stainless steel, carbon steel, aluminum, copper, brass, and even galvanized steel. Its robust design allows it to handle different thicknesses effectively.

Q3: How do I maintain my P80 Plasma Cutting Torch?

Proper maintenance is key to extending the life of your P80 torch:

Regularly inspect and replace consumables: This includes the nozzle, electrode, swirl ring, and shield cap. These wear out over time and significantly impact cut quality.

Keep the torch clean: Remove any spatter or debris from the tip.

Check for air leaks: Ensure all connections are tight to maintain proper gas flow.

Store it properly: Protect it from dust and damage when not in use.

Q4: What are the typical consumables for a P80 torch and when should I replace them?

The primary consumables for a P80 torch are the nozzle, electrode, swirl ring, and shield cap.

You should replace consumables when you notice a degradation in cut quality, such as:

Ragged or uneven cuts

Excessive dross (slag)

Frequent arc extinguishing

A "double arc" or unstable arc

Visible wear or damage on the nozzle or electrode (e.g., a large pit in the electrode, an enlarged or oblong hole in the nozzle).

Regular inspection is the best way to determine when a replacement is needed.

Q5: Can I use a P80 torch with any plasma cutter?

While the P80 is widely compatible, it's crucial to check the specifications of your specific plasma cutting machine. Most plasma cutters are designed to work with a certain type or amperage range of torch. Always ensure your machine's output (amperage) and torch connection are suitable for the P80. When in doubt, consult your plasma cutter's manual or the torch manufacturer's guidelines.

Q6: What air pressure is recommended for a P80 torch?

The recommended air pressure for a P80 torch depends on the specific amperage you're cutting at and the material thickness. However, a general range for most cutting applications is typically between 60 PSI to 90 PSI (4 to 6 bar). Always refer to your plasma cutter's manual and the torch manufacturer's recommendations for precise settings, as incorrect pressure can affect cut quality and consumable life.

Q7: What makes the P80 torch a popular choice?

Several factors contribute to the P80's popularity:

High Efficiency: It's known for fast and clean cuts, significantly improving productivity.

Durability: Built with quality materials, it withstands demanding use and high temperatures, leading to a longer lifespan.

Precision: It delivers excellent cut quality with minimal heat distortion, reducing post-processing work.

Compatibility: The P80 is widely compatible with many different plasma cutting machines, making it a common replacement and upgrade option.

Cost-Effectiveness: Both the torch itself and its consumables are generally affordable and widely available.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių

Description

Description