Plasma Cutting-The Use of An Electric Arc to Cut Metal

Principle of The Process

Plasma cutting uses the 'transferred arc' mode. The arc is constricted between the electrode and the material to be cut, due to the gas flow used, causing the energy flow density and the temperature of the plasma jet to rise even further. The gas flow consists of active or inert gases or gas mixtures.

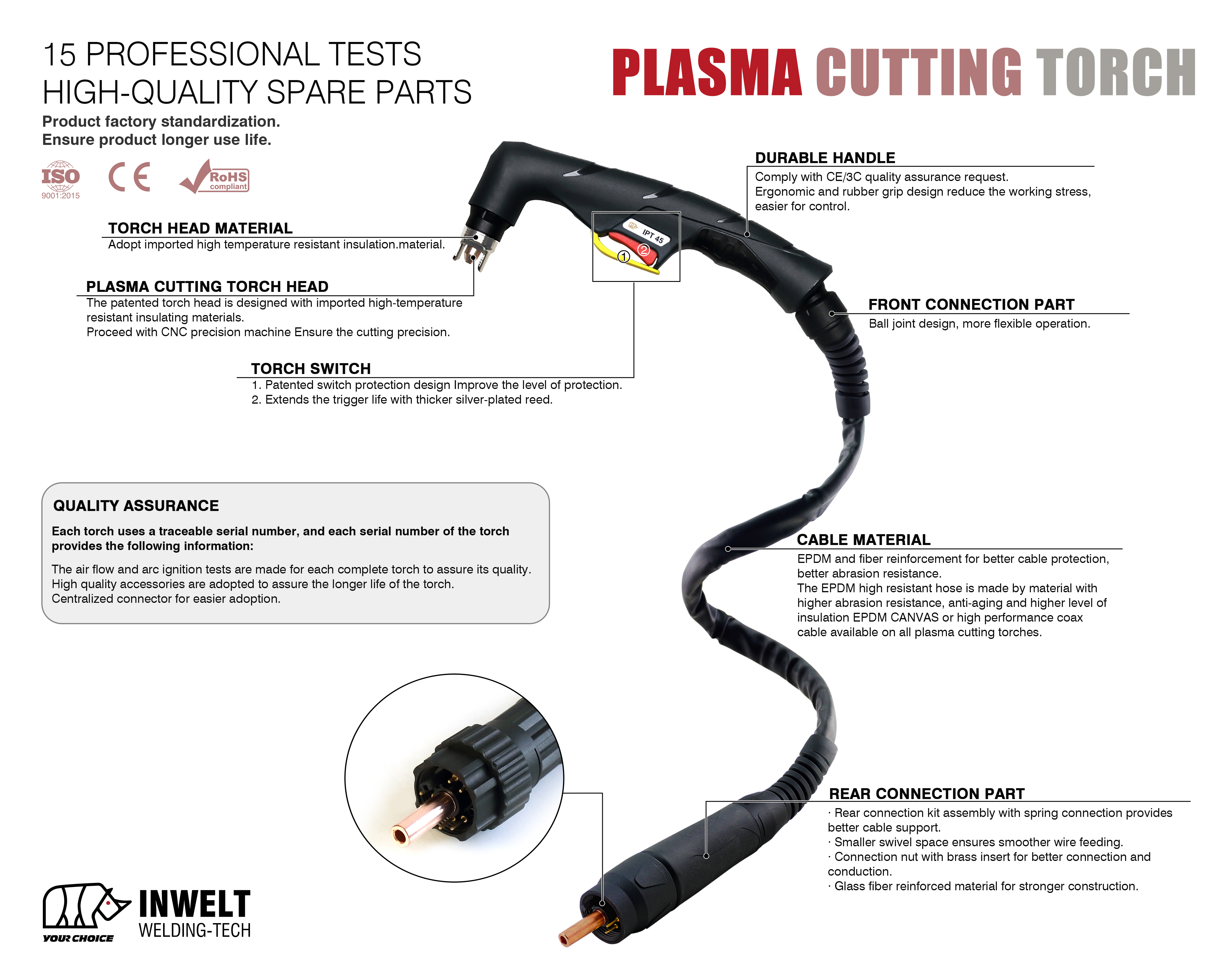

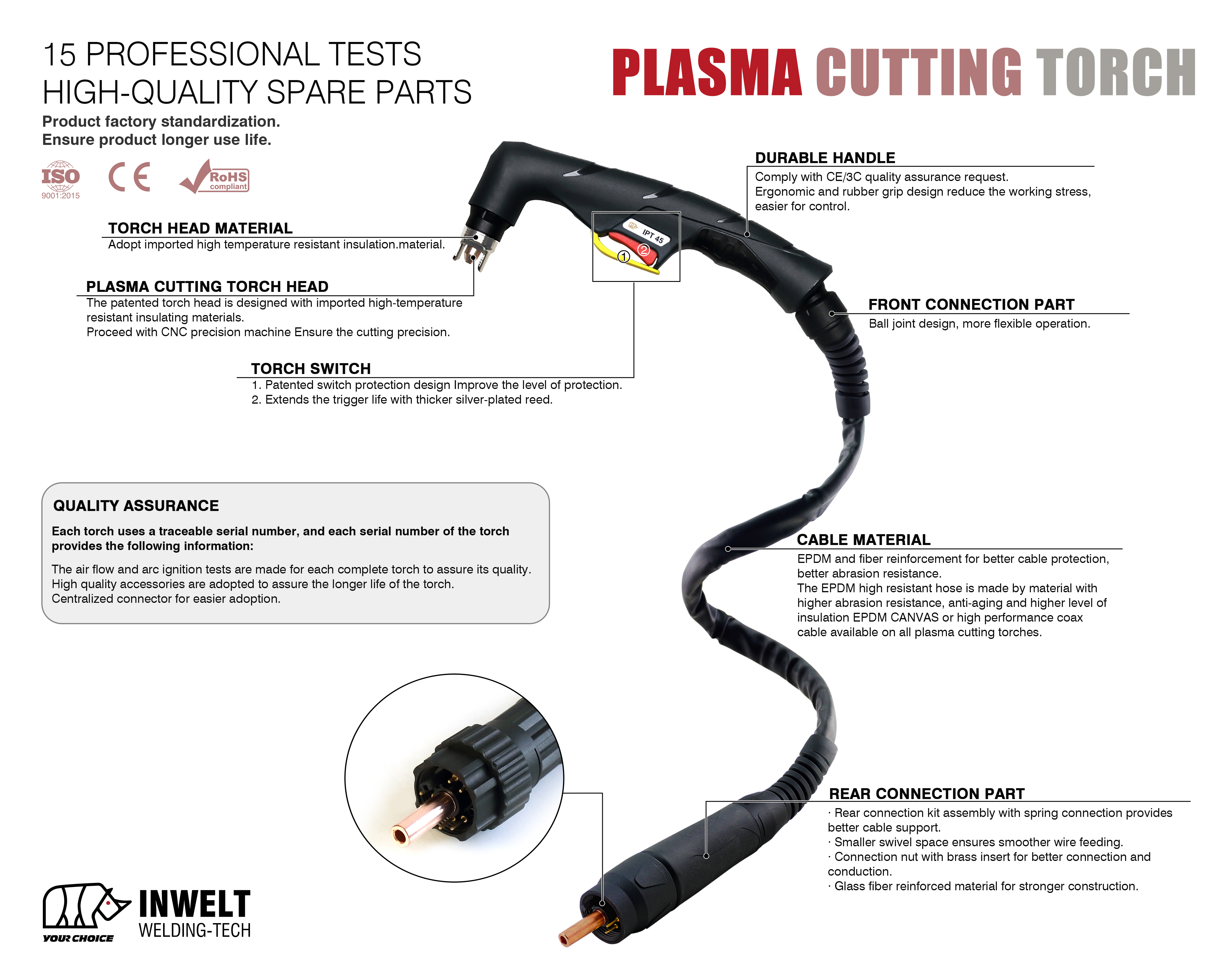

Elevate your metal fabrication with INWELT's premium plasma cutting torches – engineered for precision, durability, and efficiency. Whether you're in a repair shop or high-volume manufacturing, our manual and automated plasma cutting torches deliver clean cuts on steel, aluminum, and more. As a leading plasma torch manufacturer, we offer competitive pricing, OEM customization, and global shipping. Shop plasma cutting torches today and boost productivity by 30%!

INWELT can offers different types of Plasma cutting manual power sources, such as our LT & PT ranges.

Anyway Plasma is mostly used in automation, so we have also a wide range of automated installations to answer the most demanding needs.

Why Choose INWELT Plasma Cutting Torches? Key Advantages for Pros

INWELT stands out as a trusted plasma cutting torch supplier with 15+ years of expertise. Our torches outperform competitors in speed, safety, and cost savings – ideal for welders searching for the best plasma cutting torches for stainless steel or heavy-duty applications.

Superior Cutting Performance

High-Speed Precision: Achieve up to 8m/min on 10mm steel with minimal dross – perfect for automotive and aerospace.

Versatile Material Compatibility: Cuts conductive metals like mild steel, aluminum, copper, and galvanized steel up to 50mm thick.

Energy Efficiency: IGBT inverter tech saves 85% on power, reducing operational costs for portable plasma cutters.

Built for Durability & Safety

Robust Design: IP54-rated for dust/splatter resistance; compatible with fume extraction systems (ISO 15012-4 compliant).

Extended Consumable Life: 1,500–3,000 starts on manual models; 2x longer on automated with optimized gas flow.

Certifications: CE, RoHS, EN 60974-7 (EU); UL ANSI Z49.1 (US); ISO 9001 globally – ensuring OSHA-compliant operations.

Cost-Effective Ownership

3-Year Warranty: Peace of mind with 24/7 support and free online training.

Wholesale Options: Bulk discounts for plasma torch wholesale – contact us for custom lengths and Euro/Binzel compatibility.

Quick ROI: Lower than laser cutting costs while matching quality – ideal for small shops to large factories.

Manual Plasma Cutting Torches: Portable Power for On-the-Go Cutting

For flexible, hands-free cutting in repair shops, construction sites, or artistic metalwork, our manual plasma cutting torches (LT & PT series) are unbeatable. Search no more for handheld plasma cutting torch options – these portable units plug into 110V–240V generators for instant setup.

LT Series: Drag-and-Cut Simplicity

Power Specs: 30–80A, ideal for 110V–240V AC; pierces up to 25mm.

Ergonomic Features: Swivel neck for tight spaces; lightweight (under 2kg) for all-day use.

Best For: Aluminum welding or stainless steel repairs – best manual plasma cutting torch for beginners.

PT Series: High-Amperage Versatility

Power Specs: Up to 80A with HF start for non-touch ignition.

Safety Add-Ons: Thermal overload protection and HF noise suppression.

Consumables: PMX-compatible nozzles/electrodes; 500+ pierces per set.

Automated Plasma Cutting Torches: Precision for CNC & Robotic Systems

Scale up with our automated plasma cutting torches, integrated seamlessly into CNC tables or robotic arms. Perfect for industrial pros needing high amperage plasma torch solutions for 24/7 production – from automotive parts to aerospace components.

Advanced Tech for Industrial Efficiency

Power Specs: 100–400A on 3-phase 380V–480V; supports piercing up to 25mm.

AI Enhancements: Arc stability algorithms reduce rework by 40%; collision sensors for uninterrupted runs.

Software Integration: Preloaded DXF profiles for quick setup; real-time wear monitoring via app.

Comparison: Manual vs. Automated Plasma Torches

| Feature | Manual (LT/PT) | Automated (CNC/Robotic) |

| Power Range | 30–80A | 100–400A |

| Max Thickness | 25mm pierce / 50mm edge | 25mm pierce / 50mm edge |

| Speed | Up to 4m/min | Up to 8m/min |

| Portability | High (handheld) | Fixed (machine-mounted) |

| Best Use | Field repairs, art | Mass production |

| Consumable Life | 1,500 starts | 3,000+ starts |

How Plasma Cutting Torches Work: The Cutting Principle Explained

Plasma cutting torches use a high-velocity jet of ionized gas (plasma) created by an electric arc to melt and eject metal. Compressed air or argon/hydrogen mixes propel the plasma at 20,000°F – slicing through thick plates faster than oxy-fuel.

Step-by-Step Process

Arc Initiation: HF or pilot arc starts the plasma without touching the workpiece.

Gas Ionization: Nozzle focuses gas into superheated plasma stream.

Material Separation: Plasma melts metal; shield gas blows away molten residue for clean edges.

Shielding: Outer layer prevents oxidation, ensuring bevel-free cuts.

Frequently Asked Questions (FAQ): Manual & Automated Plasma Cutting Torches

Boost your site's rich snippets with FAQ schema markup. We've optimized these for voice search queries like "what is the best plasma cutting torch for thick metal?"

Q1: What materials can plasma cutting torches cut?

A: Conductive metals only – mild steel, stainless steel, aluminum, copper, brass, and galvanized up to 50mm. Not for non-conductive like wood or plastic.

Q2: Manual vs. automated: Which plasma cutting torch is right for me?

A: Choose manual for portability in field work; automated for precision in factories. Our LT series excels for handheld plasma torch needs.

Q3: How do I maintain my plasma cutting torch consumables?

A: Clean nozzles weekly; replace electrodes after 500 pierces. INWELT offers kits for plasma torch consumables wholesale.

Q4: Are INWELT torches compatible with Hypertherm or Lincoln systems?

A: Yes – PMX-compatible for easy swaps.

Q5: What's the warranty on your plasma cutting torches for sale?

A: 3 years limited, plus lifetime tech support. CE/UL certified for global peace of mind.

Q6: Can these torches handle high-amperage cutting for thick steel?

A: Absolutely – up to 400A on automated models for 50mm+ plates. Ideal for air plasma cutting torch pros.

Q7: Do you offer fume extraction integration?

A: Yes, all models pair with our welding fume extraction guns for OSHA compliance.

Q8: How fast is shipping for plasma cutting torches?

A: 7–20 days worldwide.

Q9: What's the difference between air and gas plasma torches?

A: Air is cost-effective for general use; argon mixes for finer cuts on aluminum.

Still have questions? Email sales1@czinwelt.com or WhatsApp +86-18112882579 for expert advice!

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių