Introduction: The Triad of Perfect Welds

Every MIG welder, from a hobbyist in their garage to a professional on the production line, has faced the same frustrating question: "Why does my weld look like that?" The answer almost always lies in the intricate dance between three critical parameters: voltage, wire feed speed (WFS), and shielding gas. Mastering these settings is the difference between a weak, messy, spatter-filled bead and a strong, clean, aesthetically pleasing weld that penetrates deeply.

MIG welding is often called an "easy" process to learn, but it's notoriously difficult to master. The machine can feel like a mysterious black box with confusing dials. This guide aims to demystify that box. We will break down each component of the MIG welding triad, explain how they interact with each other, and provide you with the knowledge and charts you need to confidently set up your machine for any material or project.

By the end of this article, you will no longer be guessing. You will understand the science behind the arc, how to diagnose common welding problems by looking at the bead, and how to systematically fine-tune your settings to achieve flawless results every time. Let's transform your welding from good to exceptional.

The Role of Shielding Gas: The Invisible Protector

Before we even touch voltage or wire speed, we must start with the environment in which the weld is formed. Shielding gas is arguably the most fundamental setting, as it directly influences arc characteristics, penetration, and bead profile.

What is Shielding Gas and Why is it Critical?

Shielding gas is an inert or semi-inert gas mixture directed over the weld pool to protect the molten metal from reactive elements in the atmosphere, primarily oxygen, nitrogen, and hydrogen. If these elements contaminate the weld, it can lead to porosity (bubbles), excessive spatter, brittleness, and a significantly weakened joint.

Common Shielding Gas Types and Their Applications

1. Carbon Dioxide (CO₂)

Characteristics: An active gas. Provides very deep penetration and is inexpensive. However, it produces a harsher, less stable arc with more spatter and a rougher bead appearance compared to mixed gases.

Best For: Pure CO₂ is often used for thick material where maximum penetration is needed and appearance is secondary. It's a common, low-cost choice for heavy equipment repair and fabrication.

2. Argon (Ar)

Characteristics: An inert gas. Produces a very smooth, stable arc with minimal spatter and a clean, aesthetically pleasing bead. Provides a narrower penetration profile.

Best For: Primarily used for welding non-ferrous metals like aluminum, copper, and titanium. Rarely used alone for steel.

3. Argon and Carbon Dioxide Mixes (e.g., C25)

Characteristics: This is the "gold standard" for most MIG welding of mild steel. A 75% Argon / 25% CO₂ mix offers the best of both worlds: the stable arc and clean finish of argon, with the improved penetration of CO₂. Spatter is dramatically reduced compared to pure CO₂.

Best For: The most common choice for general fabrication, automotive work, and hobbyist welding on mild steel. It produces high-quality welds with minimal cleanup.

4. Argon and Oxygen Mixes (e.g., 98% Ar / 2% O₂)

Characteristics: The small amount of oxygen stabilizes the arc and improves fluidity of the weld pool, leading to a flatter bead profile and less undercut. It is not for use on aluminum, chromium, or copper.

Best For: Spray transfer welding on thicker mild and stainless steel.

5. Ternary Mixtures (Argon/CO₂/Helium)

Characteristics: Helium increases heat input, leading to a wider, flatter penetration profile. These specialized mixes are designed for specific outcomes on stainless steel and other alloys.

Best For: Stainless steel and other specialty alloys where specific bead geometry is required.

Demystifying Wire Feed Speed (WFS): The Amperage Control

Wire feed speed (WFS) is measured in inches per minute (IPM) and is the primary control for welding amperage. The more wire you feed into the weld per minute, the higher the amperage.

The Relationship Between WFS and Amperage

Think of it like this: the wire is the conductor for the electrical current. A longer conductor (more wire) has more resistance, which generates more heat (amperage). Therefore, adjusting the WFS dial directly controls the heat of the arc.

Too Low WFS: The wire will burn back to the tip, creating a popping sound and likely burning your contact tip. The weld will have poor penetration and may sit on top of the material without fusing (lack of fusion).

Too High WFS: The wire will advance faster than it can be melted, causing it to "birdnest" at the drive rolls and pushing the gun back. The arc will sound erratic, and you'll get excessive spatter and a tall, ropey bead.

How to Set a Starting Point for WFS

WFS is determined by material thickness. A general rule of thumb is to set your WFS and then adjust your voltage to match it.

A Useful Chart for Mild Steel with C25 Gas:

| Material Thickness (Gauge) | Material Thickness (Inches) | Recommended Wire Feed Speed (IPM) | Recommended Wire Diameter |

| 24 Ga | 0.024" | 90 - 130 | 0.023" |

| 22 Ga | 0.030" | 110 - 150 | 0.023" |

| 18 Ga | 0.048" | 180 - 220 | 0.030" |

| 16 Ga | 0.060" | 210 - 250 | 0.030" |

| 1/8" (11 Ga) | 0.125" | 240 - 290 | 0.035" |

| 3/16" | 0.188" | 300 - 350 | 0.035" or 0.045" |

| 1/4" | 0.250" | 380 - 450 | 0.045" |

Note: These are starting points. Always test on a scrap piece of the same material first!

Understanding Voltage: The Arc Length Control

Voltage controls the length of the arc and the width of the weld bead. It's a measure of electrical pressure.

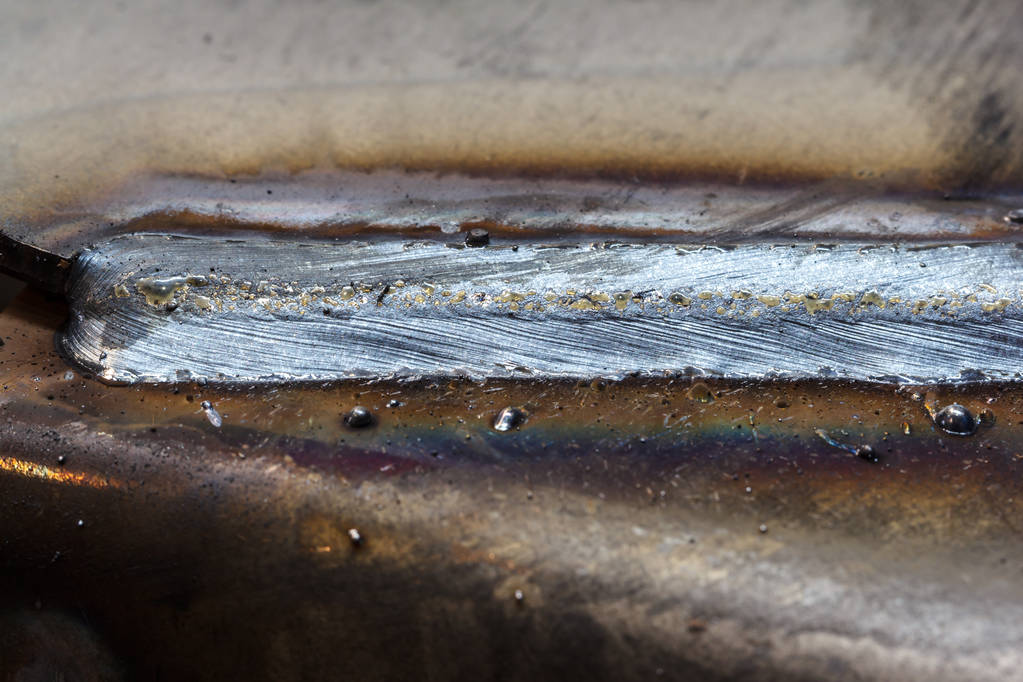

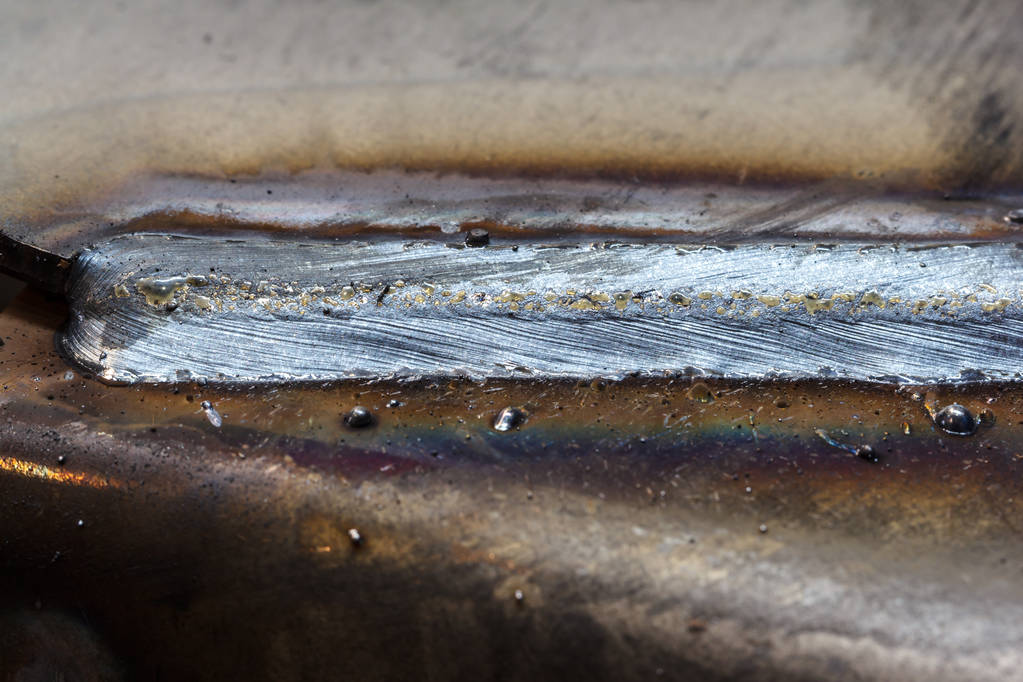

Too Low Voltage: Creates a short, "stubby" arc. The wire will dig into the material, creating a narrow, convex (high crowned) bead with poor tie-in at the toes (edges) and possible undercut. The arc will sound harsh and sputter.

Too High Voltage: Creates a long, loud, roaring arc. The weld puddle will be excessively fluid and wide, leading to a flat, wide bead with a high risk of burn-through on thinner material. Spatter will increase.

The "Sweet Spot": Listening to the Arc

The correct voltage produces a distinctive crackling or frying bacon sound. This is a steady, consistent noise. When you hear this, you know your voltage and WFS are in harmony.

The Synergy: How Voltage, WFS, and Gas Work Together

You cannot adjust one parameter in isolation. They are intrinsically linked.

The "Push" and "Pull" Relationship

Imagine Voltage and WFS are on a seesaw.

If you increase WFS (amperage/heat), you are pushing more wire into the puddle. To melt this additional wire properly and maintain the correct arc length, you typically need to increase the voltage.

If you decrease WFS, you are feeding less wire, so you need less heat to melt it. You will typically need to decrease the voltage to avoid overmelting the puddle.

Gas is the moderator of this relationship. The gas mixture you choose will define the range in which this Voltage/WFS seesaw operates. For example, the voltage required for a given WFS is generally lower with a C25 mix than it is with pure CO₂.

Practical Tuning Procedure:

SELECT your gas based on the material.

SET your wire feed speed based on material thickness (use the chart as a start).

ADJUST voltage while welding on a test piece. Listen for the steady "crackle" and look for a flat to slightly convex bead that ties in smoothly with the base metal.

FINE-TUNE: If you have excessive spatter and a ropey bead, increase voltage. If you have a convex bead and poor penetration, increase WFS and then voltage to match.

Advanced Considerations: Transfer Modes

The interaction of these three settings also determines the method, or "transfer mode," by which the molten metal moves from the wire to the weld pool.

Short Circuit Transfer: Occurs at low voltage and amperage. The wire actually touches the workpiece (shorts) multiple times per second. Ideal for thin materials and out-of-position welding.

Globular Transfer: Occurs with higher heat. Large droplets of metal transfer across the arc. This mode is prone to spatter and is generally undesirable.

Spray Transfer: Occurs at high voltage and amperage with an argon-rich gas. The metal transfers in a fine, misted spray without spatter. Excellent for high-production flat and horizontal welding on thicker materials.

Troubleshooting Common Weld Issues

Use this guide to diagnose your settings by looking at your weld:

| Weld Issue | Likely Cause | Solution |

| Excessive Spatter | Voltage too low, or CO₂ % too high | Increase voltage slightly; use Ar/CO₂ mix |

| Ropy, Convex Bead | Wire feed speed too high for voltage | Increase voltage or decrease WFS |

| Wide, Flat Bead w/ Burn-through | Voltage too high | Decrease voltage |

| Porosity (Holes) | Contaminated gas (moisture, air), insufficient gas flow | Check for leaks, ensure gas is on, increase CFH |

| Lack of Fusion | Amperage (WFS) too low, travel speed too fast | Increase WFS, slow down travel speed |

| Undercut | Voltage too high, travel speed too fast | Decrease voltage, slow down travel speed |

Conclusion: From Theory to Practice

Mastering MIG welding settings is not about memorizing numbers; it's about understanding the fundamental principles of how voltage, wire feed speed, and shielding gas interact to create a weld. It's a skill developed through practice and mindful experimentation.

Start with the guidelines and charts provided here. Always keep a notepad next to your welder. Write down your material thickness, gas type, settings, and the resulting weld quality. This logbook will become your most valuable personal reference guide, tailored specifically to your machine and your technique.

By taking control of these three dials, you elevate your work from simple attachment to crafted connection. You will spend less time grinding and more time welding, achieving stronger, cleaner, and more professional results on every project.

Ready to dial in your perfect weld? Explore our range of high-quality MIG welders and shielding gases, designed to give you consistent and reliable performance, shot after shot.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Latine

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Беларуская мова

Bosanski

Български

ქართული

Lietuvių